Method for harvesting porphyridium cruentum based on foam floatation

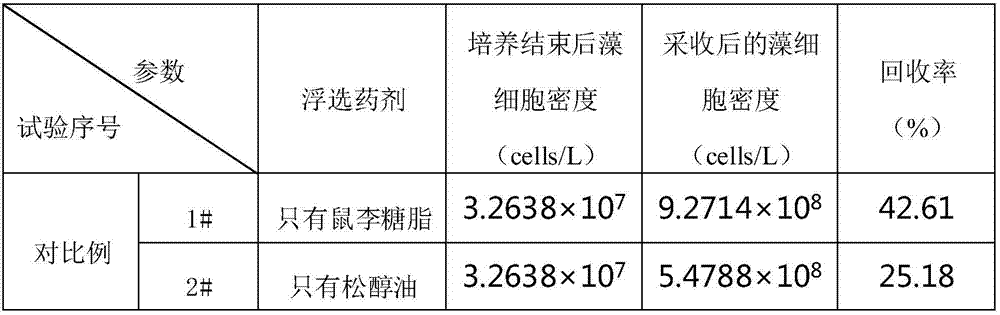

A harvesting method and foam flotation technology, applied in the direction of single-cell algae and separation of microorganisms, can solve the problem of low recovery rate of Porphyridium algae, and achieve the effects of easy industrialization, low addition amount, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for separation of Porphylococcus foam selection flotation, comprising the steps of:

[0030] (1) Pretreatment: the algae cell density of the porphyridium algae liquid to be harvested is 3.2638×10 7 cells / L, adjust the pH of the algae liquid of Porphyridum algae to be harvested to 7 by a pH regulator, and then add rhamnolipid to the algae algae to be harvested at a ratio of solid-to-liquid ratio (kg:L) of 0.05:1000 solution, protected from light at room temperature, and magnetically stirred at 800 rpm for 5 minutes to obtain the pretreated Porphyridium algae liquid;

[0031] (2) Flotation: transfer the pretreated Porphyrococcus algae liquid to a single-cell flotation machine, and then use terpineol oil at a solid-to-liquid ratio (solid-to-liquid ratio is kg: L, here refers to terpineol oil With the solid-to-liquid ratio of the algae liquid of Porphyridum algae to be harvested, the solid-to-liquid ratio of terpineol oil added in the following examples has the sa...

Embodiment 2

[0035] A method for separation of Porphylococcus foam selection flotation, comprising the steps of:

[0036] (1) Pretreatment: the algae cell density of the porphyridium algae liquid to be harvested is 3.2638×10 7cells / L, adjust the pH of the algae liquid of Porphyridum algae to be harvested to 9 through a pH regulator, and then add rhamnolipid to the algae algae to be harvested at a ratio of solid-to-liquid ratio (kg:L) of 0.09:1000 solution, at room temperature in the dark and magnetically stirred at a speed of 1200rpm for 15min to obtain the pretreated Porphyridium algae liquid;

[0037] (2) Flotation: Transfer the pretreated Porphyridium algae liquid to the single-tank flotation machine, then add pine oil at a ratio of solid-to-liquid ratio (kg:L) of 0.005:1000, and then set the aeration flow rate is 150L / h, the impeller speed is 800rpm, and the flotation stops after 10 minutes to obtain floating products and tailings wastewater;

[0038] (3) Post-treatment: use a scrape...

Embodiment 3

[0041] A method for separation of Porphylococcus foam selection flotation, comprising the steps of:

[0042] (1) Pretreatment: the algae cell density of the porphyridium algae liquid to be harvested is 3.2638×10 7 cells / L, adjust the pH of the algae liquid of Porphyridum algae to be harvested to 8 through a pH regulator, and then add rhamnolipid to the algae algae to be harvested at a ratio of solid-to-liquid ratio (kg:L) of 0.07:1000 solution, at room temperature, protected from light and magnetically stirred at a speed of 1000 rpm for 10 minutes, to obtain the pretreated Porphyridum algae liquid;

[0043] (2) Flotation: Transfer the pretreated Porphyridum algae liquid to the single-tank flotation machine, then add pinitol oil at a ratio of solid-liquid ratio (kg:L) 0.004:1000, and then set the aeration flow rate 100L / h, the impeller speed is 600rpm, and the flotation stops after 8 minutes to obtain floating products and tailings wastewater;

[0044] (3) Post-treatment: Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com