Environment-friendly temperature difference engine

An engine and temperature difference technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of large consumption of petrochemical energy, air quality decline, environmental pollution and other problems, achieve low energy consumption, slow down the temperature rise, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

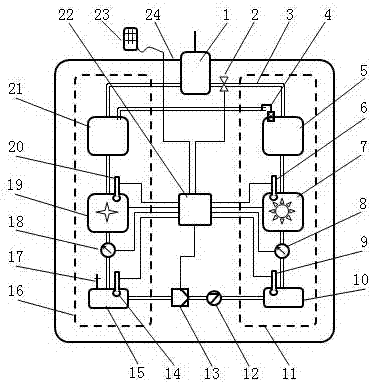

[0017] Below in conjunction with accompanying drawing, a kind of environment-friendly temperature difference engine of the present invention is described further:

[0018] Such as figure 1 As shown, it is a schematic diagram of the composition of each part of the present invention, which is quite different from ordinary internal combustion engines. General internal combustion engines must consume petrochemical fuels, mix with high-pressure air in the engine cylinder, ignite and burn, quickly generate a large amount of heat energy and release more gas, It is used to promote the movement of the cylinder piston, which essentially converts the chemical energy of the petrochemical fuel into mechanical kinetic energy; while the thermoelectric engine of the present invention does not require petrochemical fuel, and uses the medium to circulate in the closed channel, and the gas-liquid phase of the medium is alternately converted to generate high-pressure gas to push The piston and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com