Redundant system of engine rotating speed and phase sensors and control method of redundant system

A phase sensor, engine speed technology, applied in engine control, machine/engine, electrical control and other directions, can solve problems such as insurmountable, signal error, signal error, etc., to achieve convenient overall layout, stable system operation, and reduce design costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

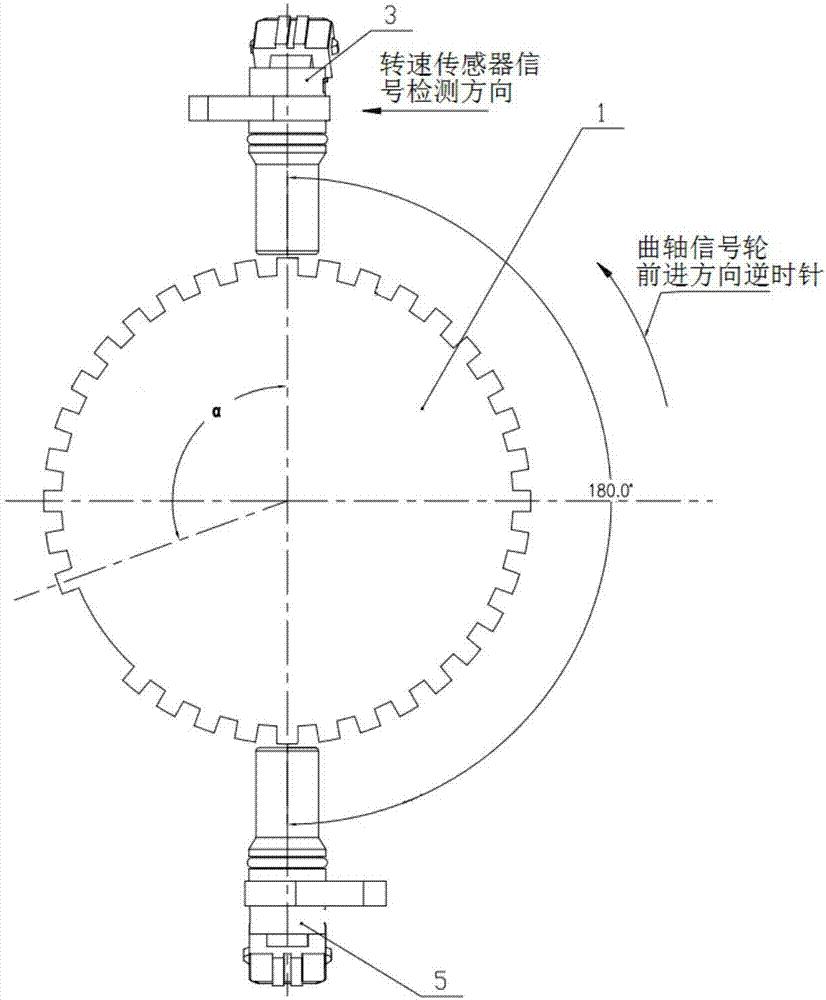

[0022] like figure 1 As shown, the first crankshaft speed sensor 3 and the second crankshaft speed sensor 5 share a crankshaft signal wheel 1, and the center line of the first crankshaft speed sensor 3 is along the rotation direction of the crankshaft signal wheel 1 and the center of the first tooth of the crankshaft signal wheel 1 after missing teeth. Lines form a certain angle, and the center line of the second crankshaft speed sensor 5 forms an angle of 180° with the centerline of the first crankshaft speed sensor 3 along the direction of rotation of the crankshaft signal wheel 1. Now, the piston of the first cylinder of the engine is at compression top dead center.

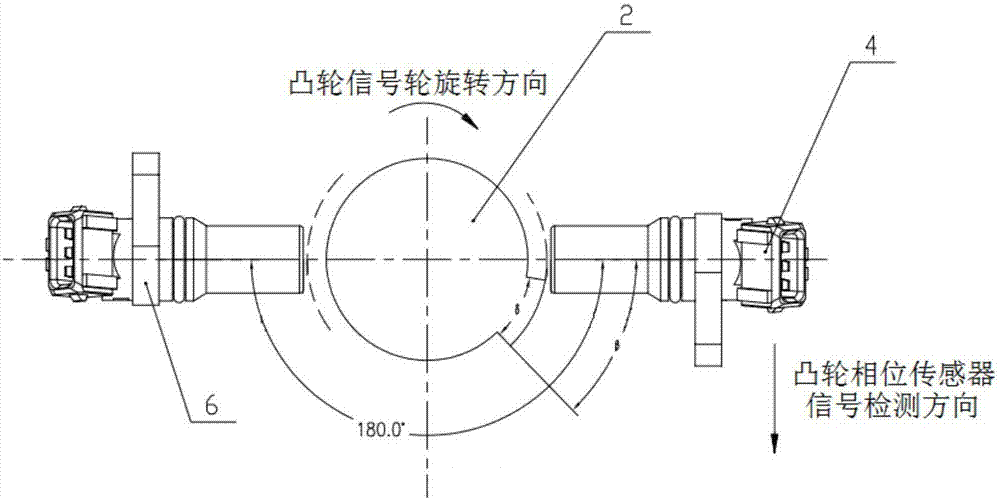

[0023] like figure 2 As shown, the first cam phase sensor 4 and the second cam phase sensor 6 share a cam signal wheel 2, and when the piston of the first cylinder of the engine is at compression top dead center, the center line of the first cam phase sensor 4 is along the rotation direction of the cam signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com