Preparation method of transition metal oxide/graphene composite material, lithium ion battery negative pole and lithium ion battery

A lithium-ion battery and transition metal technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as uneven distribution of transition metal oxides, uneven distribution of nitrogen-doped graphene, and shedding of transition metal oxides , to achieve the effects of reducing volume change, low cost, and improving electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

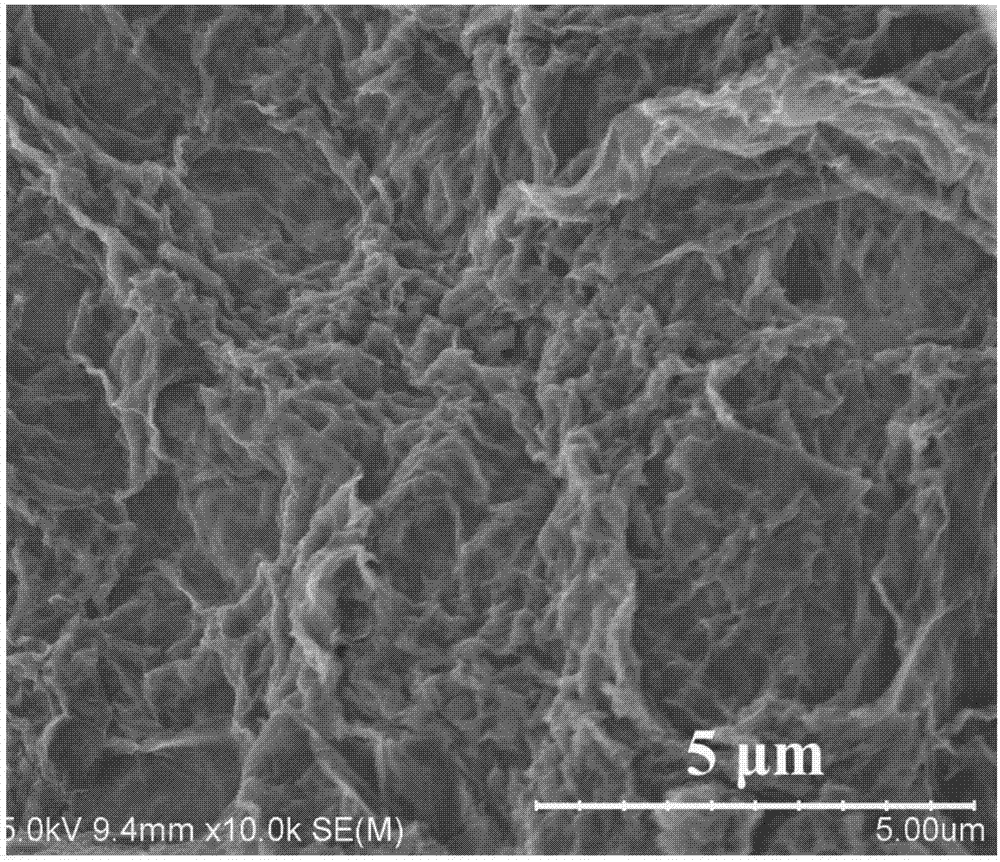

[0053] The preparation method of ferric oxide and graphene composite material comprises the following steps:

[0054] Hydrothermal process: weigh 5.0g graphite and 3.75g NaNO respectively 3 Put it into a 1L beaker, stir vigorously, slowly add 150mL of concentrated sulfuric acid, stir for 0.5 hours, then slowly add 20g of KMnO 4 , Added in 0.5 hours, and continued to stir for 20 hours, because the viscosity of the reactant increased, the stirring was stopped, and a paste-like purple-red substance was obtained. After standing for 5 days, slowly add 500mL deionized water and 30mL H 2 o 2 At this time, the color of the solution becomes more obvious bright yellow. After the solution is fully reacted, it is centrifuged and washed to obtain graphite oxide. Dissolve 70mg of graphite oxide in 80mL of deionized water, add 6mL of concentrated sulfuric acid (ρ=1.84g / cm 3 ), ultrasonically dispersed for 3 hours, the solution was moved into a small glass bottle, and then it was transfer...

Embodiment 2

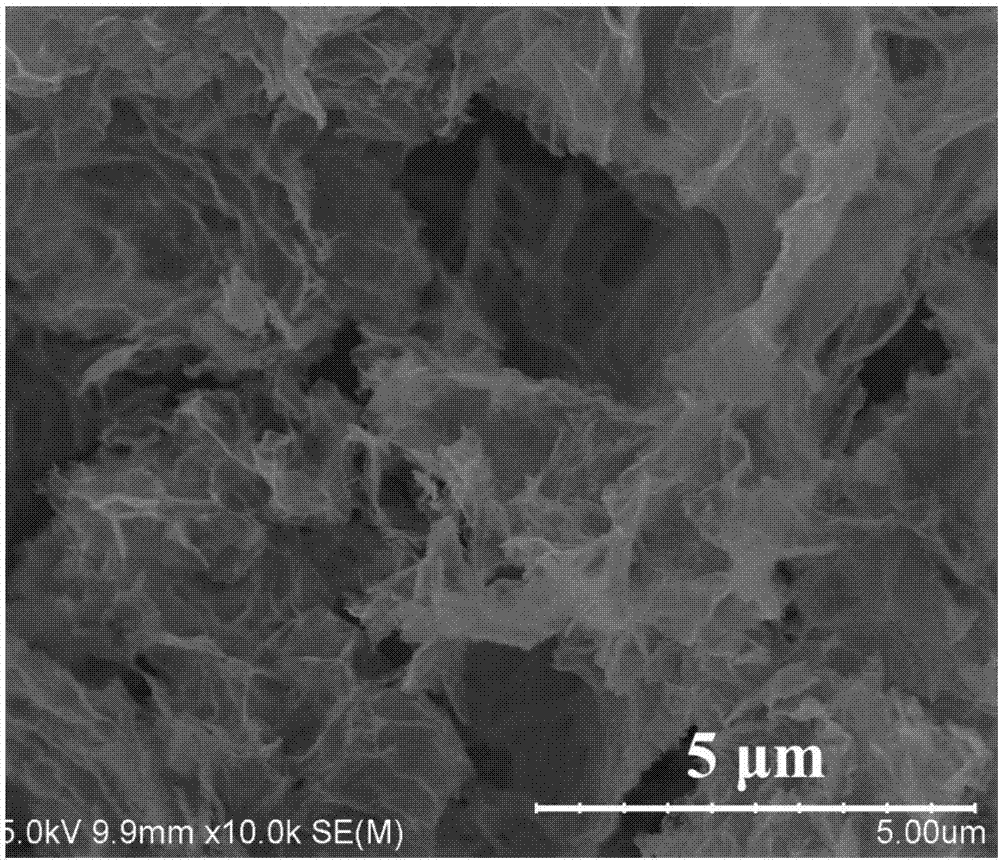

[0057] The preparation method of nickel oxide and graphene composite material comprises the following steps:

[0058] Hydrothermal process: weigh 5.0g graphite and 3.75g NaNO respectively 3 Put it into a 1L beaker, stir vigorously, slowly add 150mL of concentrated sulfuric acid, stir for 0.5 hours, then slowly add 20g of KMnO 4 , Added in 0.5 hours, and continued to stir for 20 hours, because the viscosity of the reactant increased, the stirring was stopped, and a paste-like purple-red substance was obtained. After standing for 5 days, slowly add 500mL deionized water and 30mL H 2 o 2 At this time, the color of the solution becomes more obvious bright yellow. After the solution is fully reacted, it is centrifuged and washed to obtain graphite oxide. Dissolve 100mg of graphite oxide in 80mL of deionized water, add 8mL of concentrated sulfuric acid, ultrasonically disperse for 3 hours, transfer the solution into a small glass bottle, and then transfer it to 5 hydrothermal rea...

Embodiment 3

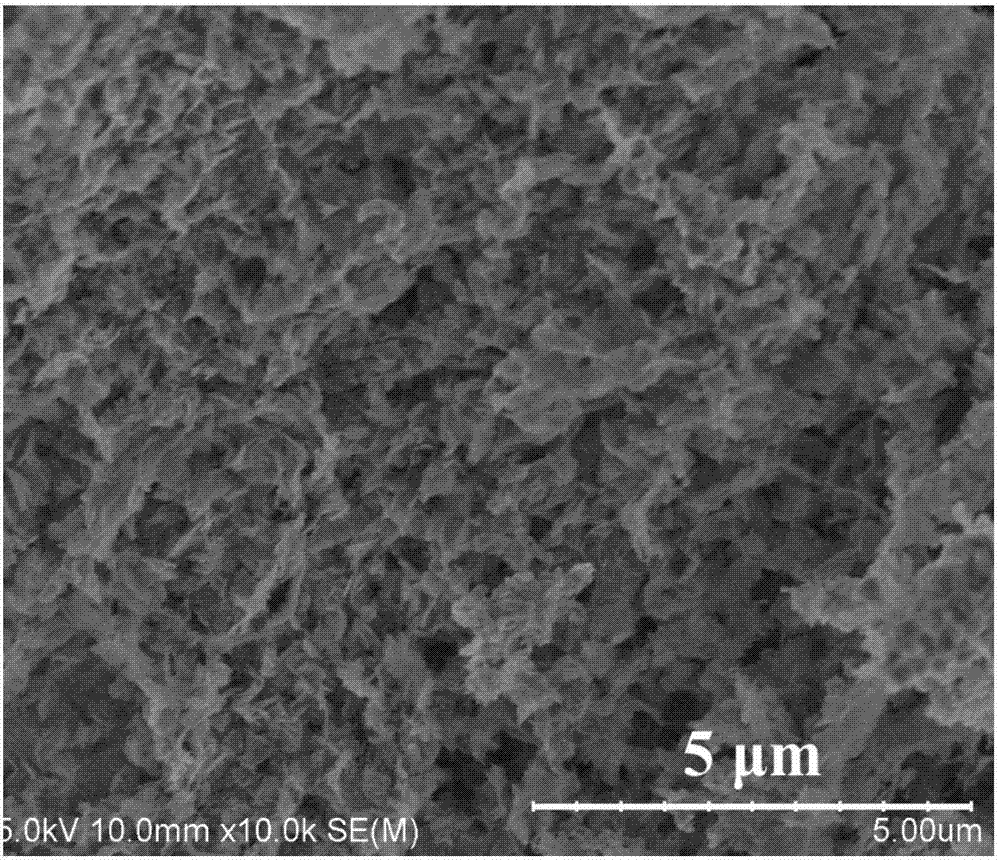

[0061] The preparation method of tricobalt tetroxide and graphene composite material comprises the following steps:

[0062] Hydrothermal process: weigh 5.0g graphite and 3.75g NaNO respectively 3 Put it into a 1L beaker, stir vigorously, slowly add 150mL of concentrated sulfuric acid, stir for 0.5 hours, then slowly add 20g of KMnO 4 , Added in 0.5 hours, and continued to stir for 20 hours, because the viscosity of the reactant increased, the stirring was stopped, and a paste-like purple-red substance was obtained. After standing for 5 days, slowly add 500mL deionized water and 30mL H 2 o 2 At this time, the color of the solution becomes more obvious bright yellow. After the solution is fully reacted, it is centrifuged and washed to obtain graphite oxide. Dissolve 120mg of graphite oxide in 80mL of deionized water, add 10mL of concentrated sulfuric acid, disperse ultrasonically for 3 hours, transfer the solution into a small glass bottle, then transfer it to 5 hydrothermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com