Fully automatic betel nut halogenating equipment

A fully automatic, betel nut technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of inability to accurately control, low work efficiency, complex equipment structure, etc., to improve the degree of automation and work efficiency, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

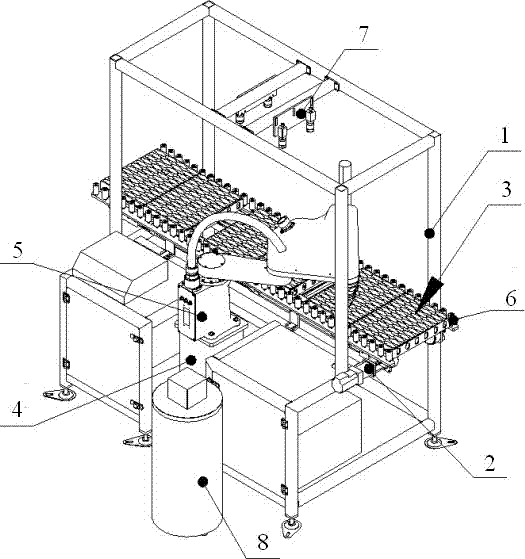

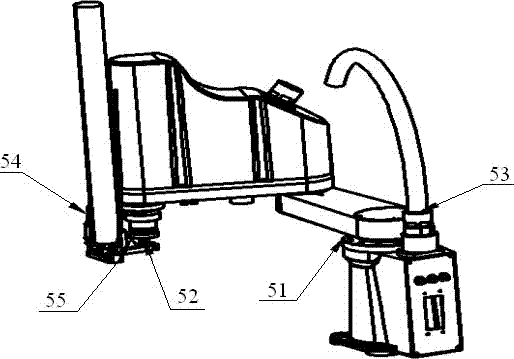

[0020] A fully automatic betel nut pointing equipment, its structure is as follows figure 1 As shown, it includes a frame assembly 1, a betel nut tray 3, a feeding conveying mechanism 2, a conveying guide mechanism 6, a visual inspection assembly 7, a halogen point mechanism 5, a heating barrel 8 and a control device. Results The brine-pointing mechanism was controlled to light the betel nut on the betel nut tray, the feeding and conveying mechanism was used to move the position of the betel nut tray on the frame assembly, and the conveying guide mechanism was used to position the betel nut tray.

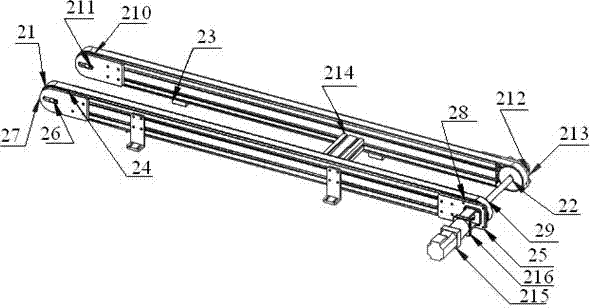

[0021] The betel nut charging tray 3 is horizontally arranged in the middle part of the frame assembly, and its structure is as follows: Figure 5 As shown, there is a notch on the betel nut tray for placing a single betel nut. The number of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com