Preparation method of core-shell carbon-coated micro-nano zirconium powder

A carbon coating, micro-nano technology, applied in the field of micro-nano metal powder coating, can solve problems such as difficult to meet application requirements, high equipment requirements, complex process, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

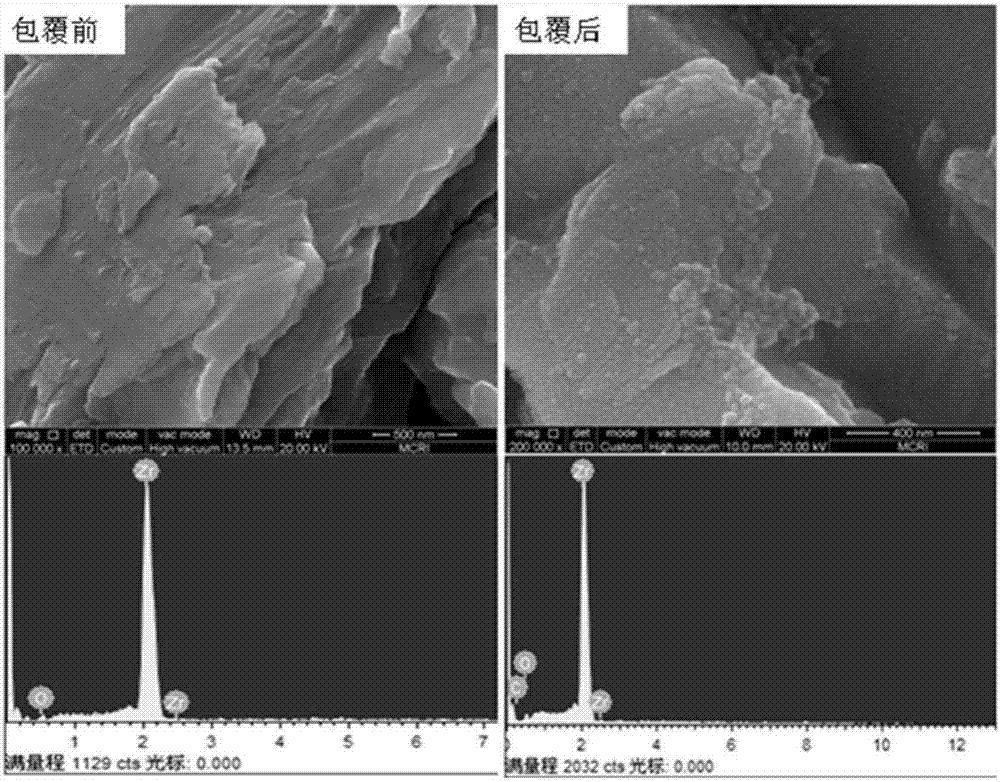

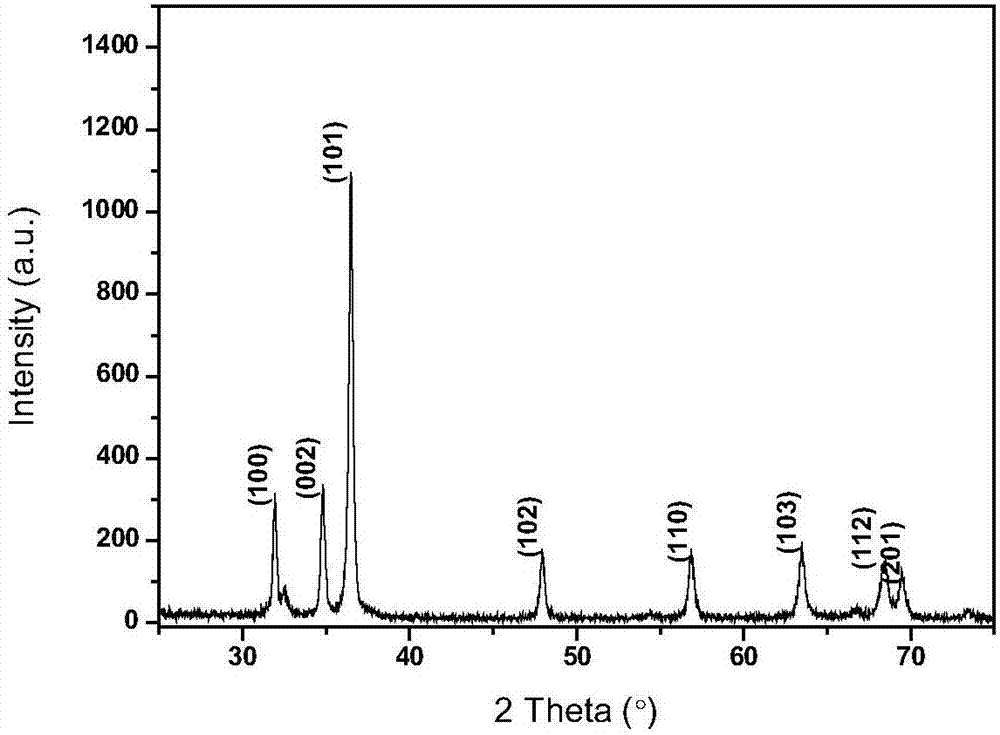

[0024] Weigh 0.2g of levodopa in 100mL of water, heat to dissolve it completely, and add 2.0g of zirconium powder with an average particle size of 5μm into the dopa solution, stir for 30min and wait for uniform dispersion, then adjust the pH of the system to 9 with concentrated ammonia water ~11, Stir and react at room temperature for 24 hours, let stand, centrifuge, pour out the supernatant after layering, wash the solid with water for several times until neutral and colorless and transparent, put it in a vacuum oven to dry;

[0025] Under an argon atmosphere, the obtained precursor was placed in a tube furnace, the temperature was programmed to rise to 400°C at 5°C / min, kept for 2 hours, and then heated to 650°C for 4 hours to obtain core-shell carbon-coated micro-nano zirconium powder.

Embodiment 2

[0027] Weigh 0.1g of levodopa in 100mL of water, heat to dissolve it completely, and add 2.0g of zirconium powder with an average particle size of 5μm into the dopa solution, stir for 30min and wait for uniform dispersion, then adjust the pH of the system to 9 with concentrated ammonia water ~11, Stir and react at room temperature for 24 hours, let stand, centrifuge, pour out the supernatant after layering, wash the solid with water for several times until neutral and colorless and transparent, put it in a vacuum oven to dry;

[0028] Under an argon atmosphere, the obtained precursor was placed in a tube furnace, the temperature was programmed to rise to 400°C at 10°C / min, kept for 2 hours, and then heated to 650°C for 4 hours to obtain core-shell carbon-coated micro-nano zirconium powder.

Embodiment 3

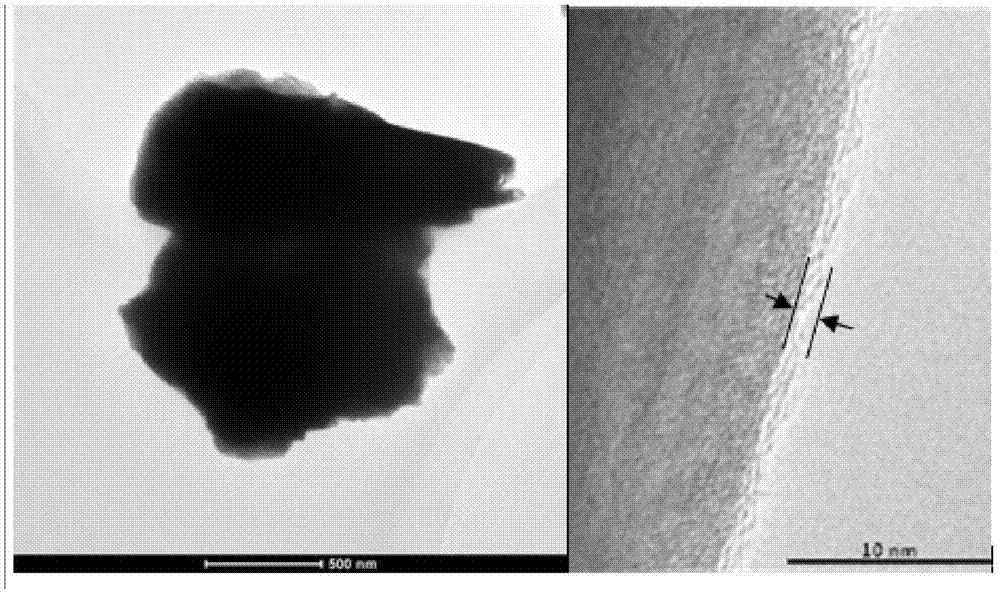

[0030] Weigh 0.1g of levodopa in 100mL of water, heat to dissolve it completely, and add 2.0g of zirconium powder with an average particle size of 80nm into the dopa solution, stir for 30min and wait for uniform dispersion, then adjust the pH of the system to 9 with concentrated ammonia water ~11, Stir and react at room temperature for 24 hours, let stand, centrifuge, pour out the supernatant after layering, wash the solid with water for several times until neutral and colorless and transparent, put it in a vacuum oven to dry;

[0031] Under an argon atmosphere, the obtained precursor was placed in a tube furnace, the temperature was programmed to rise to 400°C at 5°C / min, kept for 2 hours, and then heated to 650°C for 4 hours to obtain core-shell carbon-coated micro-nano zirconium powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com