Preparation method for boehmite nanocrystal

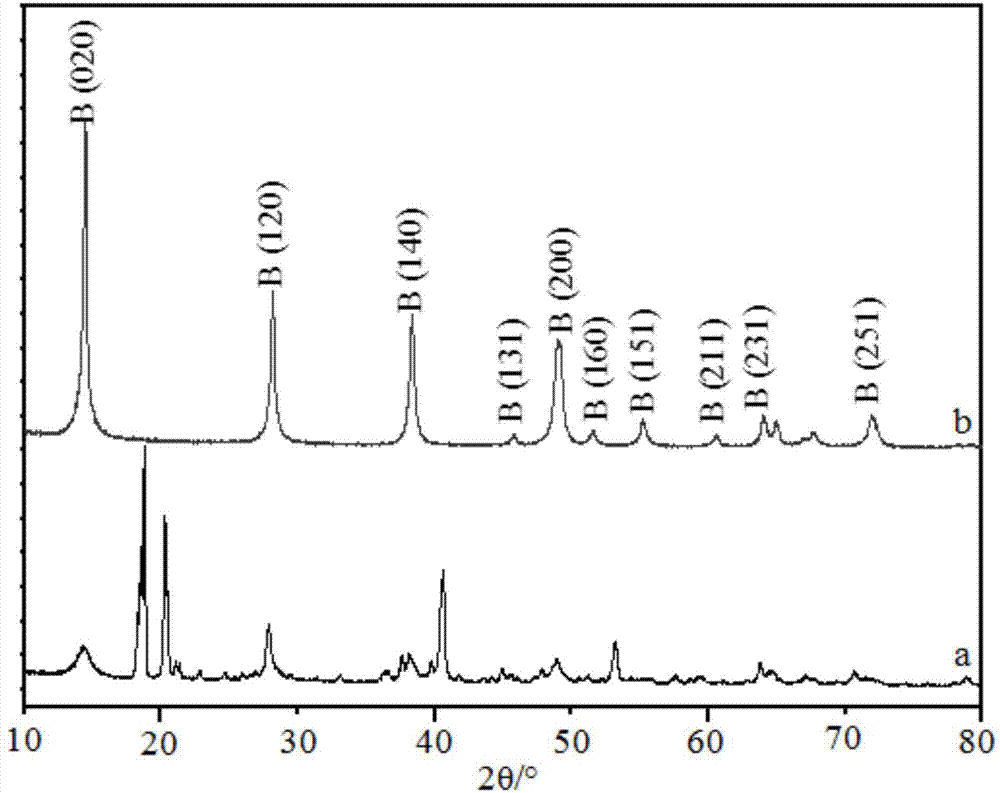

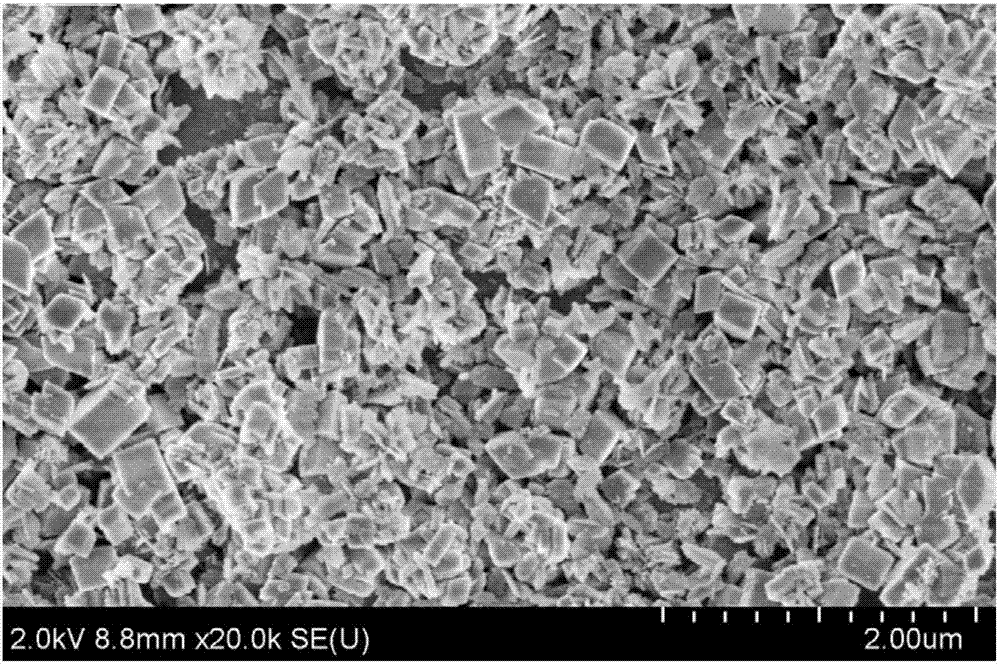

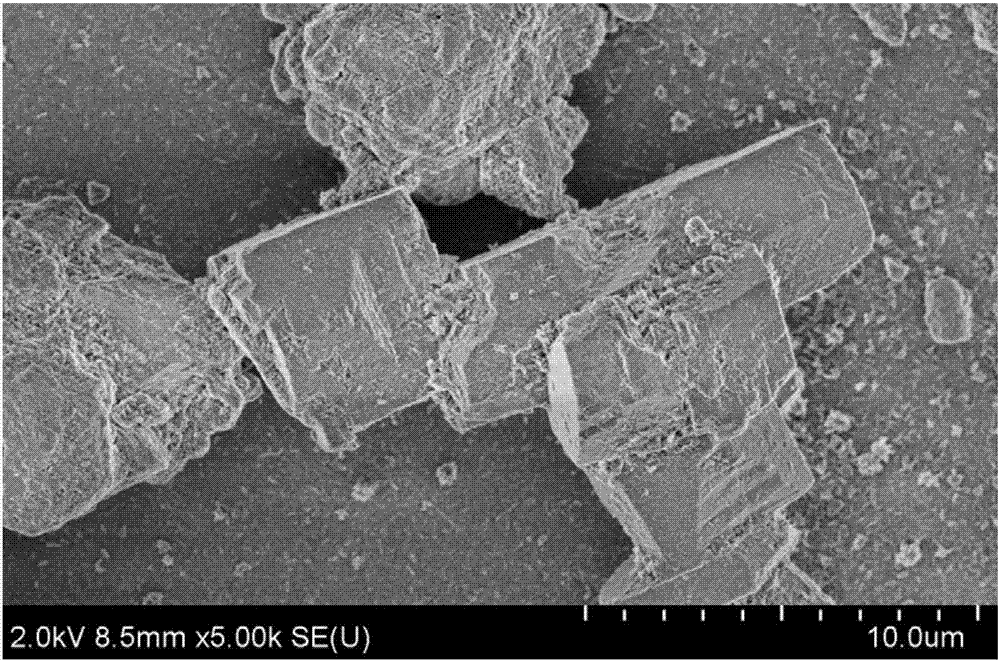

A technology of boehmite and nanocrystals, which is applied in the field of preparation of boehmite nanocrystals, can solve problems such as uneven particle size of boehmite nanocrystals, complex preparation process, and large powder size, and achieve low preparation cost, Simplified preparation procedures and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention discloses a method for preparing boehmite nanocrystals, which comprises the following steps:

[0040] Step S1, placing aluminum hydroxide powder in water according to a mass ratio of 0.2:1 to 0.8:1 to obtain a first mixed system.

[0041] Specifically, the aluminum hydroxide powder described herein may be at least one of pseudo-boehmite, diaspore, gibbsite, gibbsite, nord gibbsite, and gibbsite, Or a mixture of boehmite and at least one of the above.

[0042] In the embodiments of the present application, it is preferable to use the product obtained by the displacement reaction of aluminum powder and water, which is a mixture of gibbsite and boehmite, and the mass percentage of gibbsite reaches 80%-85%, The mass percentage of boehmite is only about 15% to 20%.

[0043] Preferably, the mass ratio of aluminum hydroxide powder to water is controlled to be 0.2:1 to 0.4:1.

[0044] Step S2: Adjust the pH value of the first mixed system to 6-10 to obtain a second mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com