Preparation method of high molecular weight R-polylactic acid-low molecular weight L-polylactic acid mixing fiber and product

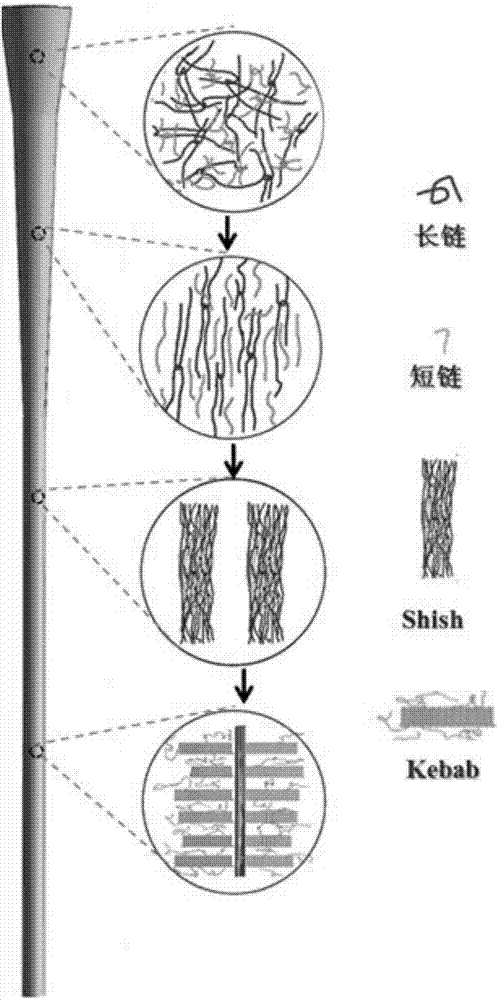

A technology of right-handed polylactic acid and left-handed polylactic acid, which is applied in the direction of conjugated synthetic polymer artificial filament, melt spinning method, stretch spinning method, etc., can solve the problem of difficult to obtain PLA fiber, slow crystallization of polylactic acid, and affecting performance and other issues, to achieve the effect of promoting the generation of shish, controllable production process, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take the weight average molecular weight as 5×10 5 g / mol HPDLA with a weight average molecular weight of 1.5×10 5 g / mol of LPLLA as starting material.

[0029] Dissolve 10g of HPDLA and 10g of LPLLA in 150ml of dichloromethane, stir magnetically for 3 hours at room temperature, pour the mixed solution into 50ml of absolute ethanol while stirring to obtain a precipitate with a mass ratio of HPDLA / LPLLA of 1:1, and place it in a vacuum oven Dry to obtain the masterbatch.

[0030] 10g of the above-mentioned masterbatch and 40g of LPLLA were melt-extruded and granulated in a micro-extruder at 240°C to obtain a HPDLA / LPLLA blend;

[0031] The blend was melt-spun at a spinning temperature of 240°C, a winding speed of 100m / min, a hot drawing temperature of 100°C, and a draw ratio of 2 times to obtain PLA blended fibers.

[0032] Specific test methods: 1) Use a single fiber heat shrinkage tester to test the hot air shrinkage rate of PLA blended fibers. The test temperature i...

Embodiment 2

[0038] Take the weight average molecular weight as 10×10 5 g / mol HPDLA with a weight average molecular weight of 1.5×10 5 g / mol of LPLLA as starting material.

[0039] Dissolve 10g of HPDLA and 10g of LPLLA in 150ml of dichloromethane, stir magnetically for 3 hours at room temperature, pour the mixed solution into 50ml of absolute ethanol while stirring to obtain a precipitate with a mass ratio of HPDLA / LPLLA of 1:1, and place it in a vacuum oven Dry to obtain the masterbatch.

[0040] 10g of the above-mentioned masterbatch and 40g of LPLLA were melt-extruded and granulated in a micro-extruder at 240°C to obtain a HPDLA / LPLLA blend;

[0041] The blend was melt-spun at a spinning temperature of 250°C, a winding speed of 120m / min, a hot drawing temperature of 120°C, and a draw ratio of 2.5 times to obtain PLA blended fibers.

[0042] The test method of shrinkage in hot air and shrinkage in boiling water is the same as in Example 1.

[0043] The hot air shrinkage rate of the ...

Embodiment 3

[0045] Take the weight average molecular weight as 10×10 5 g / mol HPDLA with a weight average molecular weight of 1.5×10 5 g / mol of LPLLA as starting material.

[0046]Dissolve 10g of HPDLA and 10g of LPLLA in 150ml of dichloromethane, stir magnetically for 3 hours at room temperature, pour the mixed solution into 50ml of absolute ethanol while stirring to obtain a precipitate with a mass ratio of HPDLA / LPLLA of 1:1, and place it in a vacuum oven Dry to obtain the masterbatch.

[0047] 10g of the above-mentioned masterbatch and 40g of LPLLA were melt-extruded and granulated in a micro-extruder at 220°C to obtain a HPDLA / LPLLA blend;

[0048] The blend was melt-spun at a spinning temperature of 255°C, a winding speed of 200m / min, a hot drawing temperature of 120°C, and a draw ratio of 3.5 times to obtain PLA blended fibers.

[0049] The test method of shrinkage in hot air and shrinkage in boiling water is the same as in Example 1.

[0050] The hot air shrinkage rate of the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com