SCR denitration reactor

A denitrification reactor and reactor technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of reduced reaction efficiency of SCR denitrification reactor, complex structure of flue gas diversion device, unreasonable design, etc. Achieve the effect of saving reaction cost, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

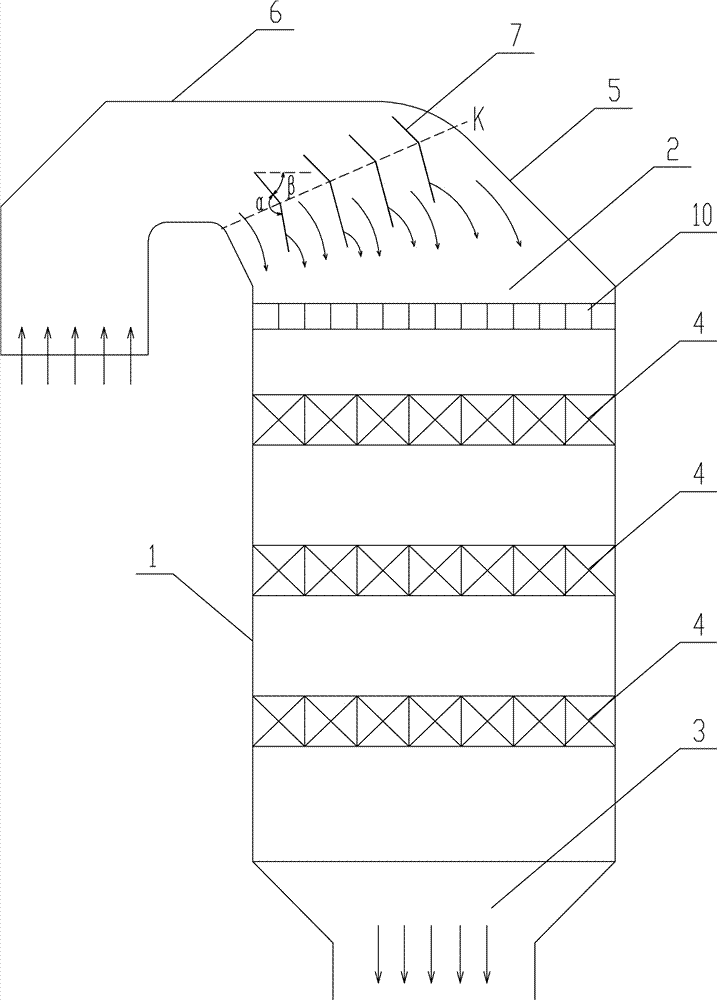

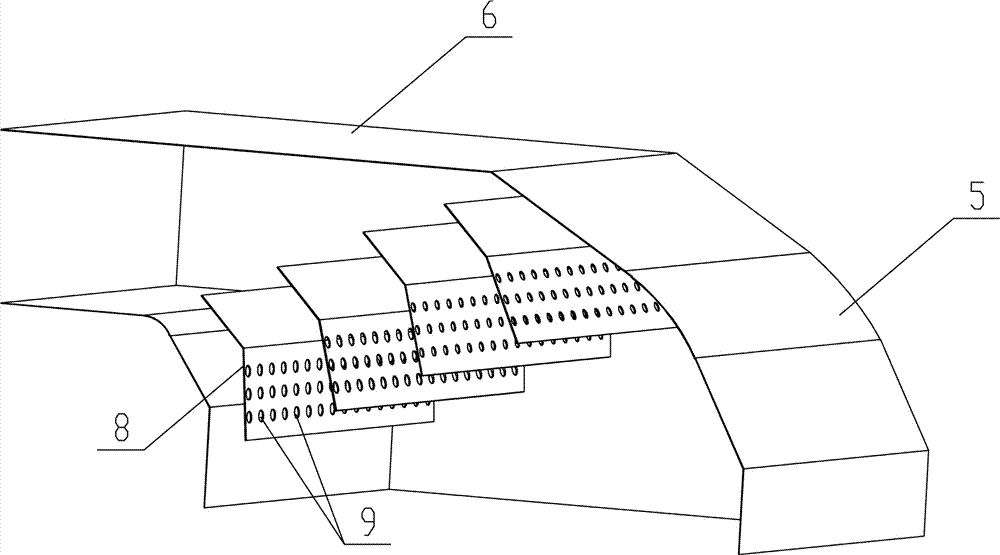

[0013] see figure 1 , figure 2 , a kind of SCR denitration reactor, has reactor body 1, and reactor body 1 has upper side air inlet 2 and lower side air outlet 3, and multilayer denitration catalyst 4 is arranged in reactor body 1, and in reactor body The air inlet end of 1 is connected to the intake flue 6 through the angled flue 5; a group of smoke guides 7 are arranged in the angled flue 5, and the smoke guides 7 include four guides arranged side by side. Flow sheet 8, flow guide sheet 8 is composed of two flat plates to form a folded structure, and the range of the fold angle α is 130 to 160 degrees. The fold points of each flow guide sheet are distributed on the same straight line, and the straight line is figure 1 K is used to indicate; on the deflector 8, the angle β between the flat plate arranged on the side of the air inlet flue 6 and the horizontal plane ranges from 45 to 50 degrees, and the angle β arranged on the air inlet end of the reactor body 1 A number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com