Electrowetting device with spacer and preparation method of electrowetting device

A spacer and electrowetting technology, applied in the field of electrowetting, can solve problems such as device center collapse, complex manufacturing process, and functional failure, and achieve the effects of preventing internal collapse, low operation difficulty, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

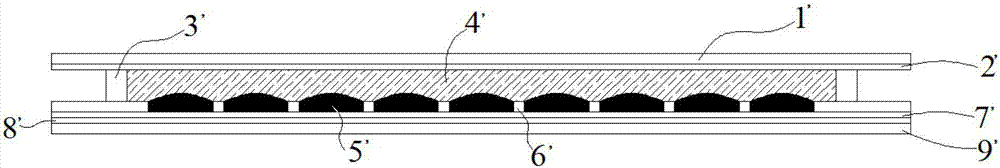

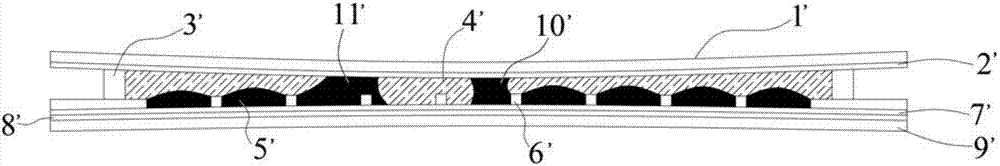

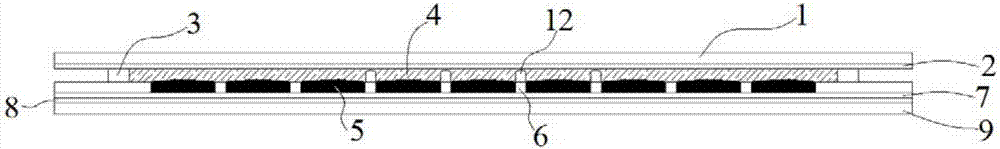

[0031] The present invention provides an electrowetting device with spacers, the cross-sectional view of which is as image 3 As shown, it includes an upper substrate, a lower substrate, and a packaging frame 3 that encapsulates the upper and lower substrates. The upper substrate includes an upper support plate 1 and a first electrode 2, and the lower substrate includes The lower support plate 9, the second electrode 8, the hydrophobic insulating layer 7 and the pixel wall 6. The electrowetting device also includes a non-polar liquid 5 and a polar solution 4. The non-polar solution 5 is evenly filled in the pixel wall 6 In the enclosed multiple pixel grids, the polar solution 4 is filled in the sealed cavity formed by the upper substrate and the lower substrate. The upper surface of the pixel wall 6 is provided with multiple spacers 12, which are randomly dispersed On the pixel wall 6, it can be on the upper surface of the horizontal wall or the vertical wall of the pixel wall 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com