Application of environment-friendly enzyme in restoration of soil polluted by heavy metal and restoration method

An environmentally friendly enzyme and technology for polluted soil, applied in the restoration of polluted soil and other directions, can solve problems such as secondary pollution costs, and achieve the effects of short repair cycle, simple preparation method, and improved repair efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 Remediation of industrial site heavy metal polluted soil

[0062] 1. A leaching agent for heavy metal-contaminated soil, i.e., an environmentally friendly enzyme, is prepared from three components: kitchen waste, water and brown sugar; wherein, the kitchen waste is composed of the following raw materials in weight percentage: fruit 40%, Vegetables 50%, Plant Leaves 10%:

[0063] The fruit is selected from one or more of oranges, lemons, apples, peaches, melons, and bananas;

[0064] The vegetables are selected from one or more of leafy vegetables, root tubers or fruit vegetables;

[0065] Wherein the plant leaves are selected from one or more of orange leaves, corn leaves, and landscaping pruned leaves.

[0066] 2. According to the above parts by weight, the eluting agent selects the raw materials of each component respectively for subsequent use, and its application method comprises the following steps:

[0067] (1) Preparation of natural acidic washing...

Embodiment 2

[0072] Embodiment 2 Remediation of Farmland Heavy Metal Contaminated Soil

[0073] 1. A leaching agent for heavy metal-contaminated soil, i.e., an environmentally friendly enzyme, is prepared from three components: kitchen waste, water and brown sugar; wherein, the kitchen waste is composed of the following raw materials in weight percentage: fruit 40%, Vegetables 50%, Plant Leaves 10%:

[0074] The fruit is selected from one or more of oranges, lemons, apples, peaches, melons, and bananas;

[0075] The vegetables are selected from one or more of leafy vegetables, root tubers or fruit vegetables;

[0076] Wherein the plant leaves are selected from one or more of orange leaves, corn leaves, and landscaping pruned leaves.

[0077] 2. According to the above parts by weight, the eluting agent selects the raw materials of each component respectively for subsequent use, and its application method comprises the following steps:

[0078] (1) Preparation of natural acidic washing ag...

Embodiment 3

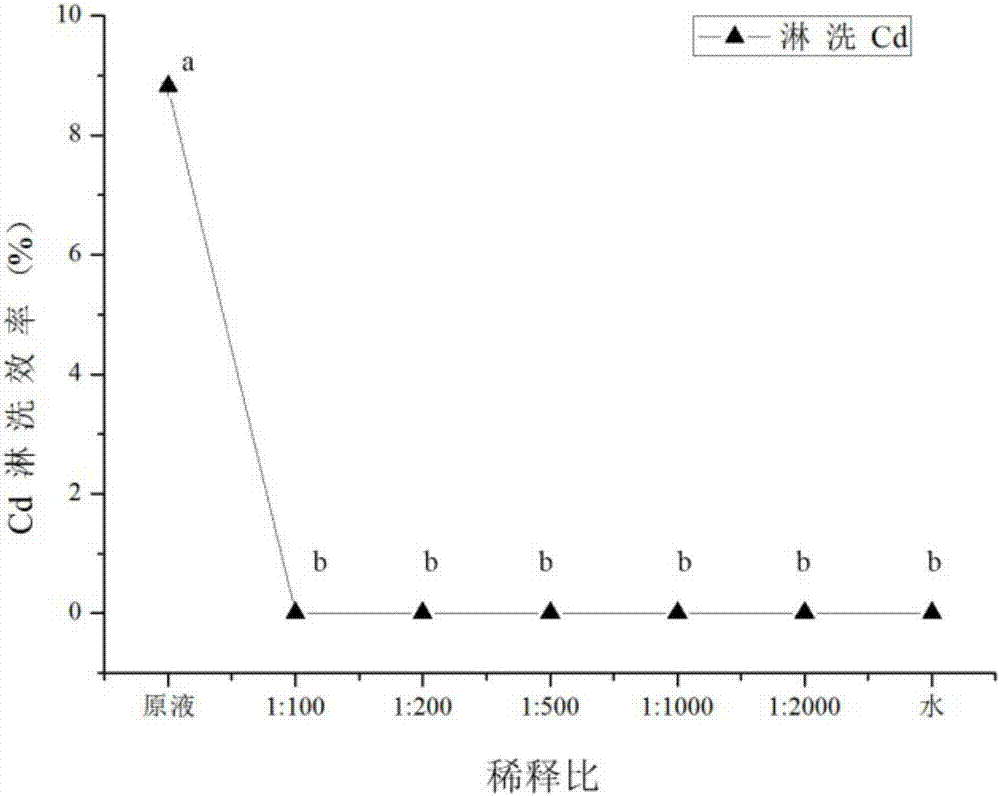

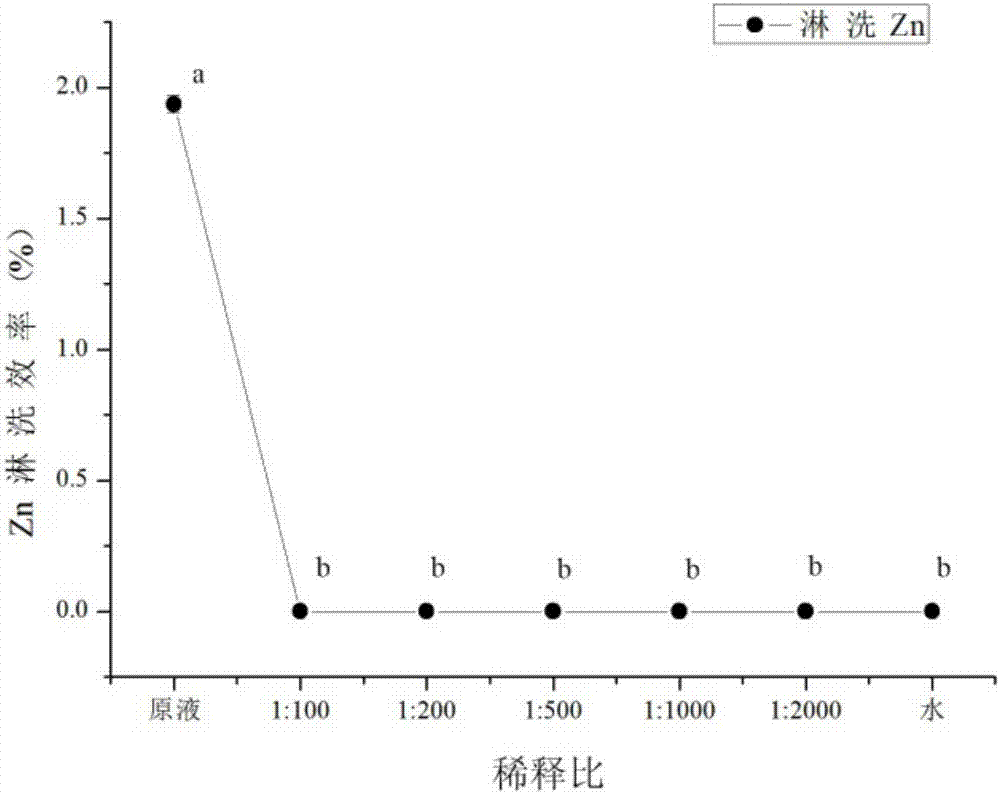

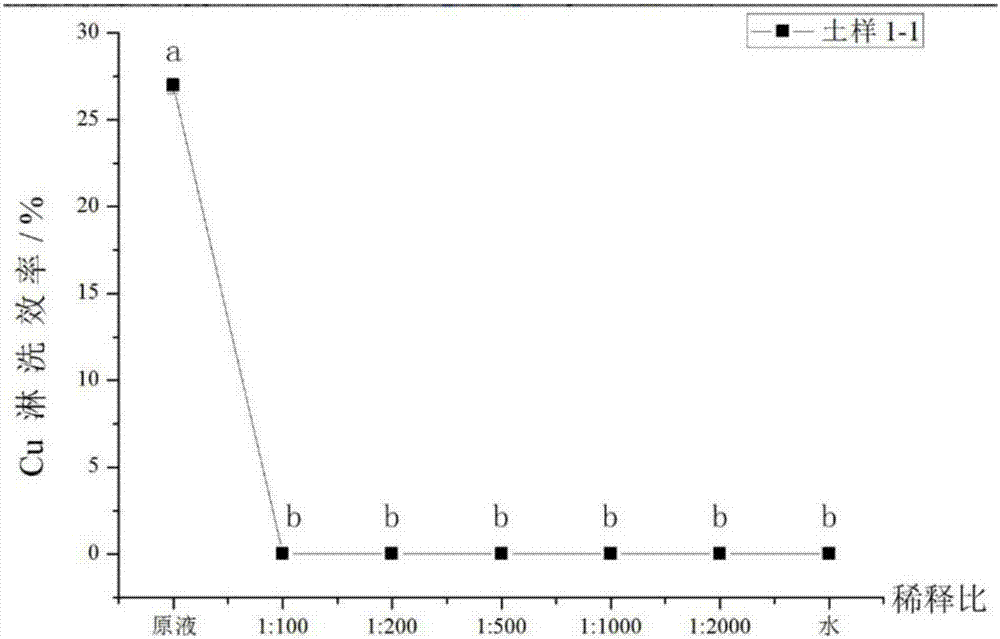

[0081] The impact of embodiment 3 different dilution ratios on the rinse effect

[0082] 1. Washing method

[0083] Environmentally friendly enzymes made from 50% fruits and 50% vegetables were diluted with water in different proportions, and the industrial site soils with very serious heavy metal pollution were washed separately (Cd 106mg / kg, Zn 14430mg / kg, Cu 220 mg / kg, Pb2371mg / kg, Ni 37.1mg / kg, Mn 2.93g / kg), the solid-to-liquid ratio is 1g:3mL, shake and rinse for 1h, and observe the influence of different dilution ratios on the rinse effect.

[0084] 2. Washing results

[0085] Depend on Figure 1 to Figure 5 It can be seen that when the dilution ratio of the environmental protection enzyme is 1:0 to 100, the leaching effect on the soil of industrial sites with serious heavy metal pollution is better. The efficiency is the best, respectively reaching 8.81%, 1.94%, 27%, 9.5% and 25%. However, if the dilution ratio exceeds 1:100, the rinsing effect is not obvious. So ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com