Cleaning device used for titanium-magnesium alloy door plank

A technology of cleaning device and titanium-magnesium alloy, used in grinding/polishing safety devices, metal processing equipment, machine tools for surface polishing, etc., can solve the problems of low degree of automation, achieve obvious speed advantages, avoid dust adhesion, and ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

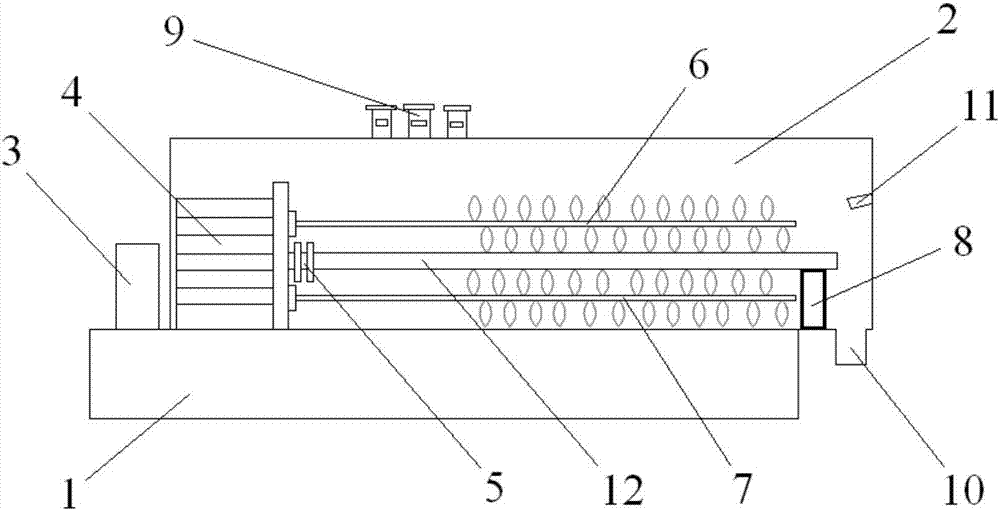

[0022] A cleaning device for a titanium-magnesium alloy door panel, characterized in that it includes a base 1, a sealed cabin 2, a console 3, a motor 4, a clamping part 5, a first polishing roller 6, a second polishing roller 7, and a bracket 8 , a blower 9, a dust bag 10, an ultrasonic oscillator 11, wherein the sealed cabin 2 and the console 3 are respectively fixedly connected to the upper surface of the base 1, and the motor 4 is fixedly connected to the upper surface of the base 1 and is located in the sealed cabin 2 Inside, the motor 4 is connected to the console 3 through wires, the first polishing roller 6 is connected to the motor 4 through its own central axis, the second polishing roller 7 is connected to the motor 4 through its own central axis, and the clamping part 5 is fixed Connected on the outer surface of the motor 4, the bracket 8 is fixedly connected on the upper surface of the base 1 and is located inside the sealed cabin 2, the upper surface of the bracke...

Embodiment 2

[0029] A cleaning device for a titanium-magnesium alloy door panel, characterized in that it includes a base 1, a sealed cabin 2, a console 3, a motor 4, a clamping part 5, a first polishing roller 6, a second polishing roller 7, and a bracket 8 , a blower 9, a dust bag 10, an ultrasonic oscillator 11, wherein the sealed cabin 2 and the console 3 are respectively fixedly connected to the upper surface of the base 1, and the motor 4 is fixedly connected to the upper surface of the base 1 and is located in the sealed cabin 2 Inside, the motor 4 is connected to the console 3 through wires, the first polishing roller 6 is connected to the motor 4 through its own central axis, the second polishing roller 7 is connected to the motor 4 through its own central axis, and the clamping part 5 is fixed Connected on the outer surface of the motor 4, the bracket 8 is fixedly connected on the upper surface of the base 1 and is located inside the sealed cabin 2, the upper surface of the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com