Preparation method of green vitriol

A technology of green alum and evaporative crystallization, applied in the direction of ferric sulfate, etc., can solve the problems of low purity and high cost of green alum, and achieve the effect of wide source and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

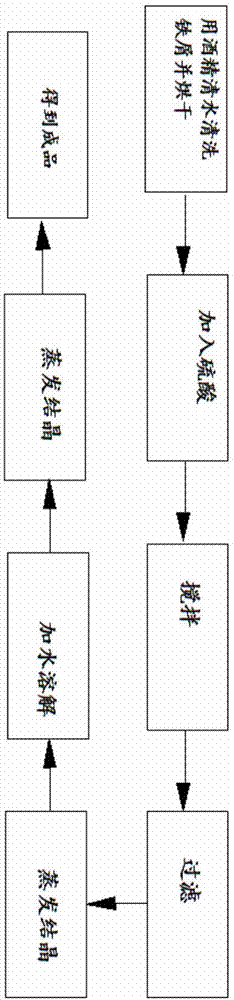

[0014] refer to figure 1 , the preparation method of a kind of vitriol of the present invention comprises the following steps:

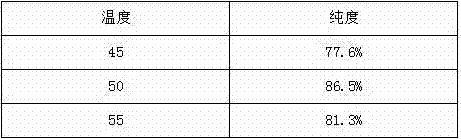

[0015] Wash a portion of scrap iron with alcohol, then wash and dry with distilled water, add a portion of 3mol / L sulfuric acid and keep stirring, filter the resulting solution, place an iron block on the filtered filter paper, and put the filtrate in Evaporate and crystallize by heating in a nitrogen atmosphere. When the solution has an obvious crystal film, measure the temperature with a thermometer and keep the temperature at 45 degrees. When 1 / 5 of the solution is left, filter the mixture, slowly add the obtained filter residue to distilled water and stir to heat Until the crystals are completely dissolved, the solution is evaporated and crystallized, the temperature is kept at 45 degrees, and the purity of ferric sulfate is measured by infrared spectroscopy.

Embodiment 2

[0017] refer to figure 1 , the preparation method of a kind of vitriol of the present invention comprises the following steps:

[0018] Wash a portion of scrap iron with alcohol, then wash and dry with distilled water, add a portion of 3mol / L sulfuric acid and keep stirring, filter the resulting solution, place an iron block on the filtered filter paper, and put the filtrate in Heating, evaporating and crystallizing in a nitrogen atmosphere, measuring the temperature with a thermometer when an obvious crystal film appears in the solution, keeping the temperature at 50 degrees, and filtering the mixture when 1 / 5 of the solution is left, slowly adding the obtained filter residue into distilled water and stirring and heating Until the crystals are completely dissolved, the solution is evaporated and crystallized, the temperature is kept at 50 degrees, and the purity of ferric sulfate is measured by infrared spectroscopy.

Embodiment 3

[0020] refer to figure 1 , the preparation method of a kind of vitriol of the present invention comprises the following steps:

[0021] Wash a portion of scrap iron with alcohol, then wash and dry with distilled water, add a portion of 3mol / L sulfuric acid and keep stirring, filter the resulting solution, place an iron block on the filtered filter paper, and put the filtrate in Evaporate and crystallize by heating in a nitrogen atmosphere. When the solution has an obvious crystal film, measure the temperature with a thermometer and keep the temperature at 55 degrees. When 1 / 5 of the solution is left, filter the mixture, slowly add the obtained filter residue to distilled water and stir to heat Until the crystals are completely dissolved, the solution is evaporated and crystallized, the temperature is kept at 55 degrees, and the purity of ferric sulfate is measured by infrared spectroscopy.

[0022] The data were combined to compare the purity of magnesium sulfate crystals at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com