Sludge reduction reaction system and treatment method

A technology of reaction system and treatment method, applied in the field of sludge reduction reaction system and treatment, can solve the problems of unfavorable large-scale popularization and application, low efficiency of ozone utilization, complex equipment structure, etc., and achieve simple structure, small footprint, The effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

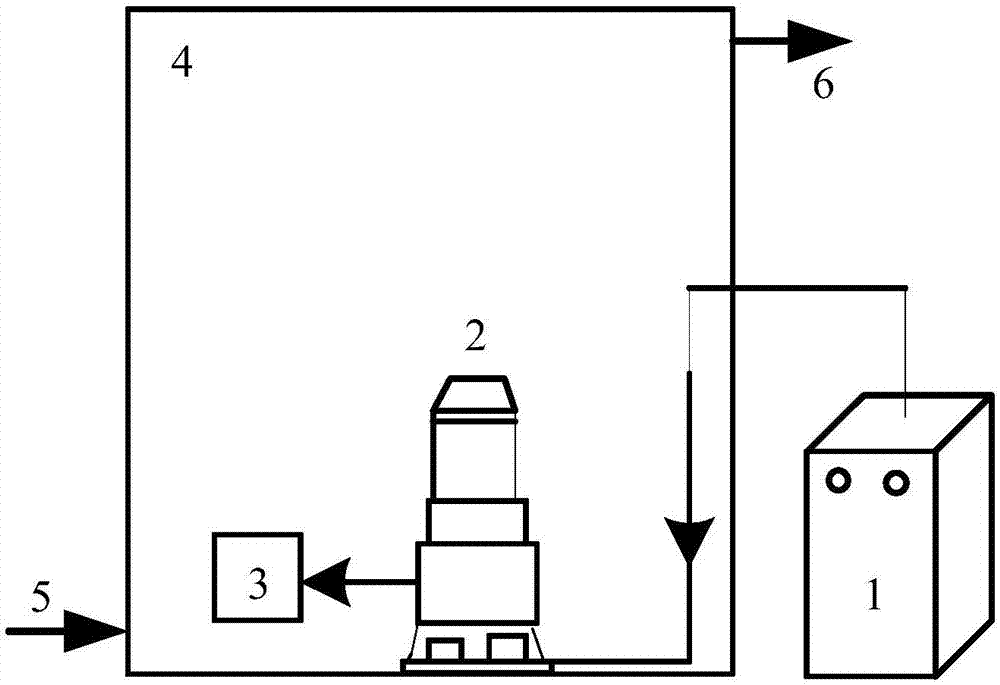

[0039] In this embodiment, sludge reduction is carried out aiming at the low dosage of ozone in the reaction tank 4 .

[0040] The 30g / h ozone generator 1 is installed outside the 30L reaction tank 4, and the submersible sewage pump 2 and releaser 3 are installed inside the reaction tank 4. A sludge inlet 5 is connected to the bottom of the reaction tank 4, and a sludge outlet 6 is connected to the upper part.

[0041] The gas outlet of the ozone generator 1 is connected to the inlet of the submersible sewage pump 2 through a trachea, and the outlet of the submersible sewage pump 2 is connected to the inlet of the releaser 3 .

[0042] The sludge with MLSS concentration of 14.14g / L is filled with the reaction tank 4, and then the sludge feeding is stopped. Then start the ozone generator 1 and the submersible sewage pump 2. The inlet of the submersible sewage pump 2 uses negative pressure to suck in ozone gas and sludge at the same time, mix in the pump to form a mixture of oz...

Embodiment 2

[0046] In this embodiment, sludge reduction is carried out by increasing the dosage of ozone in the reaction tank 4 .

[0047] The 25.5g / h ozone generator 1 is installed outside the 40L reaction tank 4, and the submersible sewage pump 2 and the releaser 3 are installed inside the reaction tank 4. A sludge inlet 5 is connected to the bottom of the reaction tank 4, and a sludge outlet 6 is connected to the upper part.

[0048] The gas outlet of the ozone generator 1 is connected to the inlet of the submersible sewage pump 2 through a trachea, and the outlet of the submersible sewage pump 2 is connected to the inlet of the releaser 3 .

[0049] The sludge with MLSS concentration of 14.14g / L is filled with the reaction tank 4, and then the sludge feeding is stopped. Then start the ozone generator 1 and the submersible sewage pump 2. The inlet of the submersible sewage pump 2 uses negative pressure to suck in ozone gas and sludge at the same time, mix in the pump to form a mixture...

Embodiment 3

[0053] In this embodiment, sludge reduction is carried out by increasing the dosage of ozone in the reaction tank 4 .

[0054] The 30g / h ozone generator 1 is installed outside the 40L reaction tank 4, and the submersible sewage pump 2 and the releaser 3 are installed inside the reaction tank 4. A sludge inlet 5 is connected to the bottom of the reaction tank 4, and a sludge outlet 6 is connected to the upper part.

[0055] The gas outlet of the ozone generator 1 is connected to the inlet of the submersible sewage pump 2 through a trachea, and the outlet of the submersible sewage pump 2 is connected to the inlet of the releaser 3 .

[0056] The sludge with MLSS concentration of 14.14g / L is filled with the reaction tank 4, and then the sludge feeding is stopped. Then start the ozone generator 1 and the submersible sewage pump 2. The inlet of the submersible sewage pump 2 uses negative pressure to suck in ozone gas and sludge at the same time, mix in the pump to form a mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com