Preparation method of photothermal conversion device based on graphene glass, graphene glass and photothermal conversion device

A photothermal conversion, graphene technology, applied in heating devices, solar thermal energy, solar thermal devices and other directions, can solve the problems of limited wide-range application, difficult to achieve full-band spectral absorption, complex photothermal material preparation process, etc. The effect of improving the utilization rate of light energy, shortening the preparation time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the preparation of graphene glass

[0049] Highly controllable graphene nanosheets were grown directly on the cleaned soda-lime glass substrate by plasma-enhanced chemical vapor deposition technology, and directly used in photothermal conversion devices. The specific method includes the following steps:

[0050] 1) Ordinary soda-lime glass substrate cleaning:

[0051] 2) Low temperature growth of graphene:

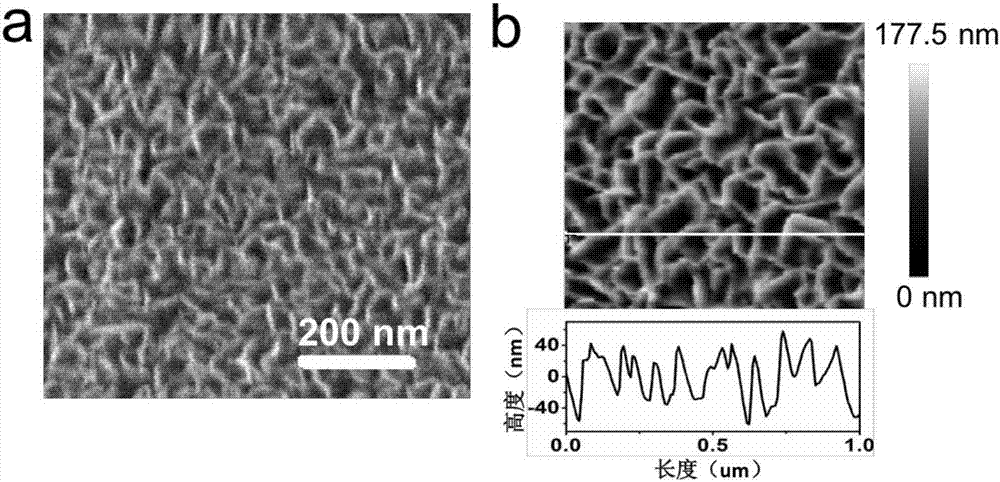

[0052] Low-temperature growth of graphene by direct current plasma-enhanced chemical vapor deposition (dc-PECVD). Place the cleaned glass substrate in the reaction chamber, pump the pressure of the reaction chamber below 0.2mbar, and then pass 200sccm Ar (heater purge) and 20sccm H 2 , the temperature was raised to 500-600°C; after the temperature was stabilized, 40sccm methane was introduced into the reaction chamber, and the pressure in the reaction chamber was controlled to be 5mbar; the graphene growth time was 2-15min to obtain graphene with di...

Embodiment 2

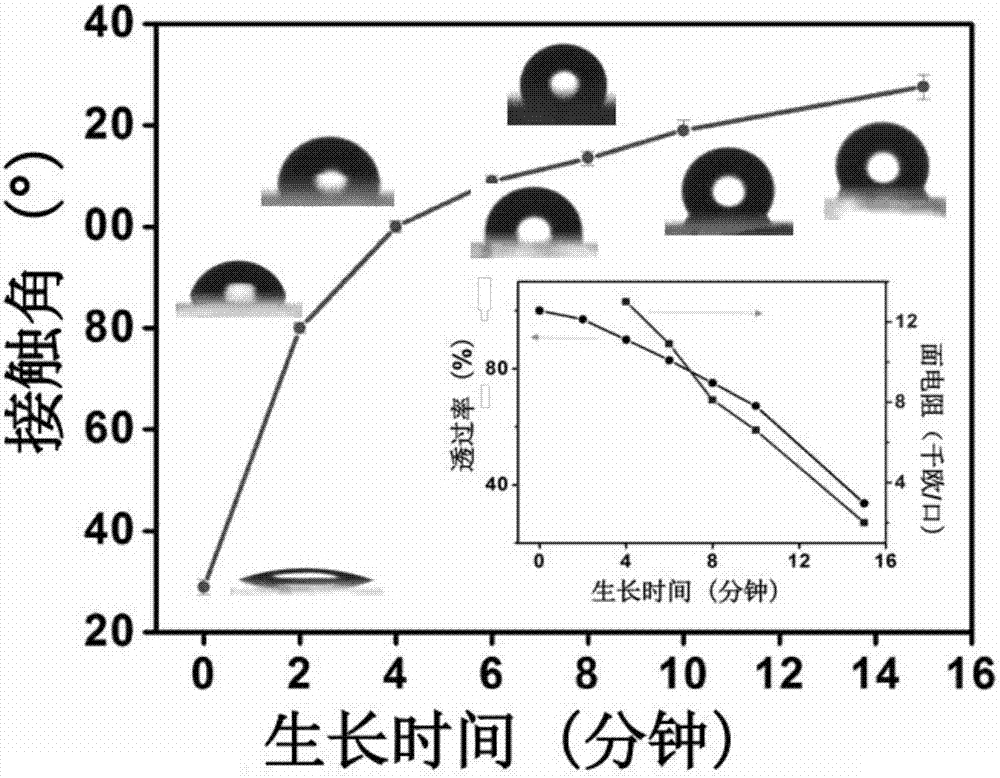

[0056] Embodiment 2: Obtaining of graphene glasses with different light-to-heat conversion efficiencies

[0057] As the height and length of the graphene nanosheets increase, the number of incident light reflections between the nanosheets increases, thereby improving the absorption efficiency of light energy. At the same time, it is also accompanied by a decrease in the transmittance of graphene glass. Ordinary soda-lime glass, as the growth substrate of graphene in the present invention, does not have any catalytic properties, indicating that the invention has wide applicability. The use of soda-lime glass as a low-cost material can reduce production costs. By adjusting different influencing parameters in the growth process, graphene glass products with different transmittances and different light-to-heat conversion efficiencies can be obtained.

[0058] Under optimized growth conditions, a series of graphene glass samples with different hydrophobicity, transmittance and sh...

Embodiment 3

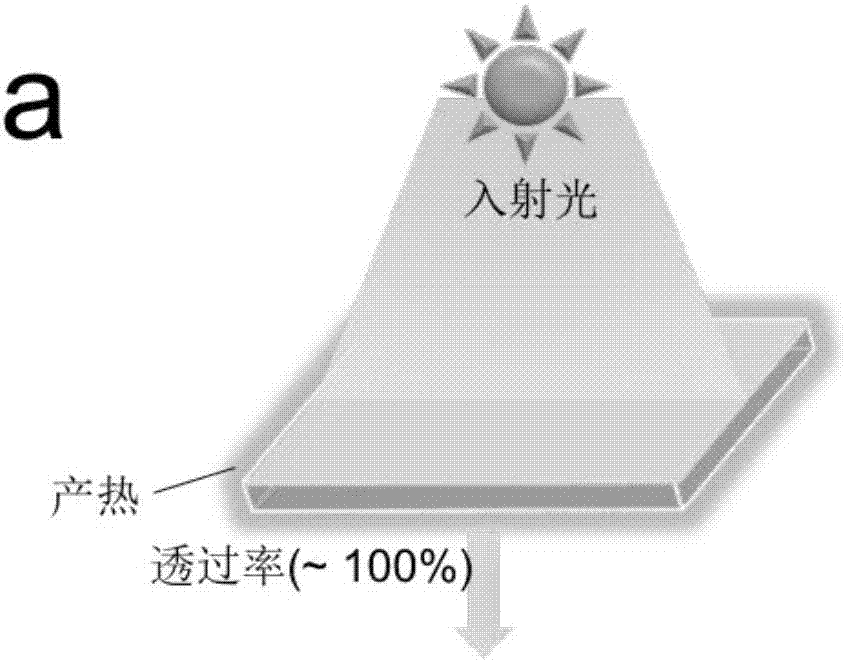

[0059] Example 3: The use of graphene glass in light-to-heat conversion

[0060] The graphene glasses with different transmittances obtained in Example 2 are directly used for light-to-heat conversion without other special treatment. Indicate as Figure 3a As shown in and b, the graphene glass is placed on the foam pad, and the simulated sunlight light source is placed directly above it. By adjusting the height of the foam pad, the simulated sunlight intensity irradiated on the surface of the graphene glass is close to a sun 1kW / m 2 , Another function of the foam pad is to reduce the influence of the external environment on the graphene glass and increase the accuracy of the measurement. Real-time detection and temperature data collection of the surface temperature of graphene glass can be realized through an infrared thermal imager. Figure 3c It is the graphene glass sample with different transmittance (respectively 100%, 97%, 83%, 75%, 34%, wherein 100% is intrinsic soda-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com