A bismuth sodium titanate-strontium titanate submicron rod and its preparation method and application

A technology of sodium bismuth titanate and sub-micron rods is applied in the field of preparation of lead-free piezoelectric ferroelectric material sub-micron rods, and can solve problems such as no reports of bismuth titanate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

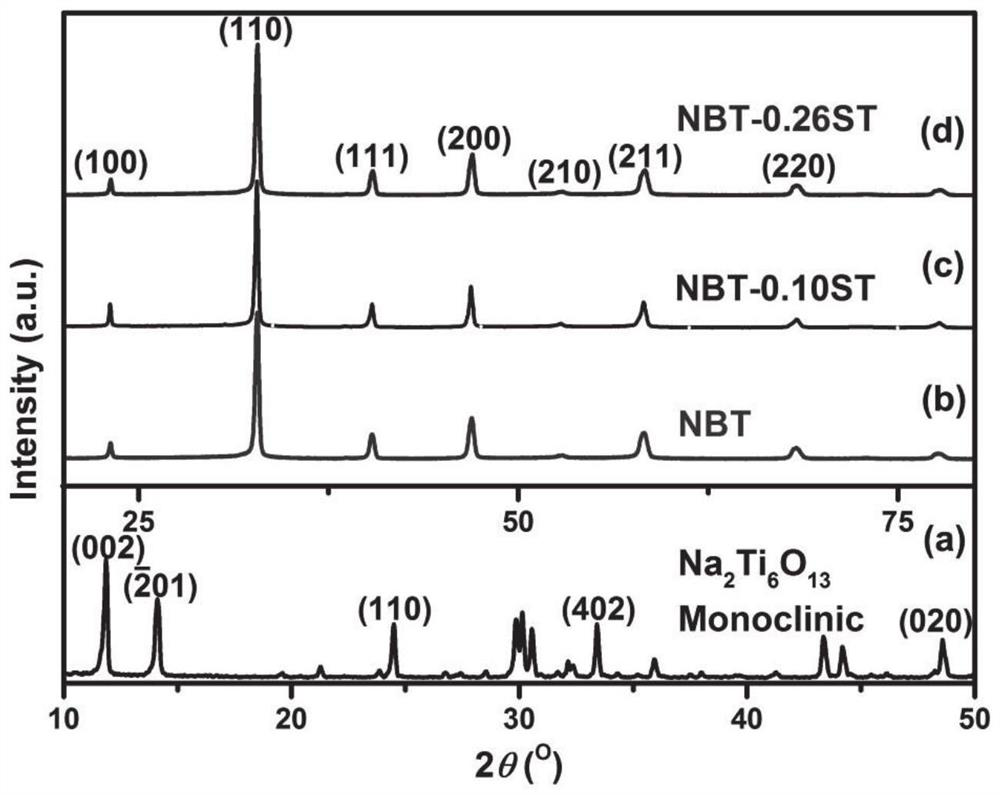

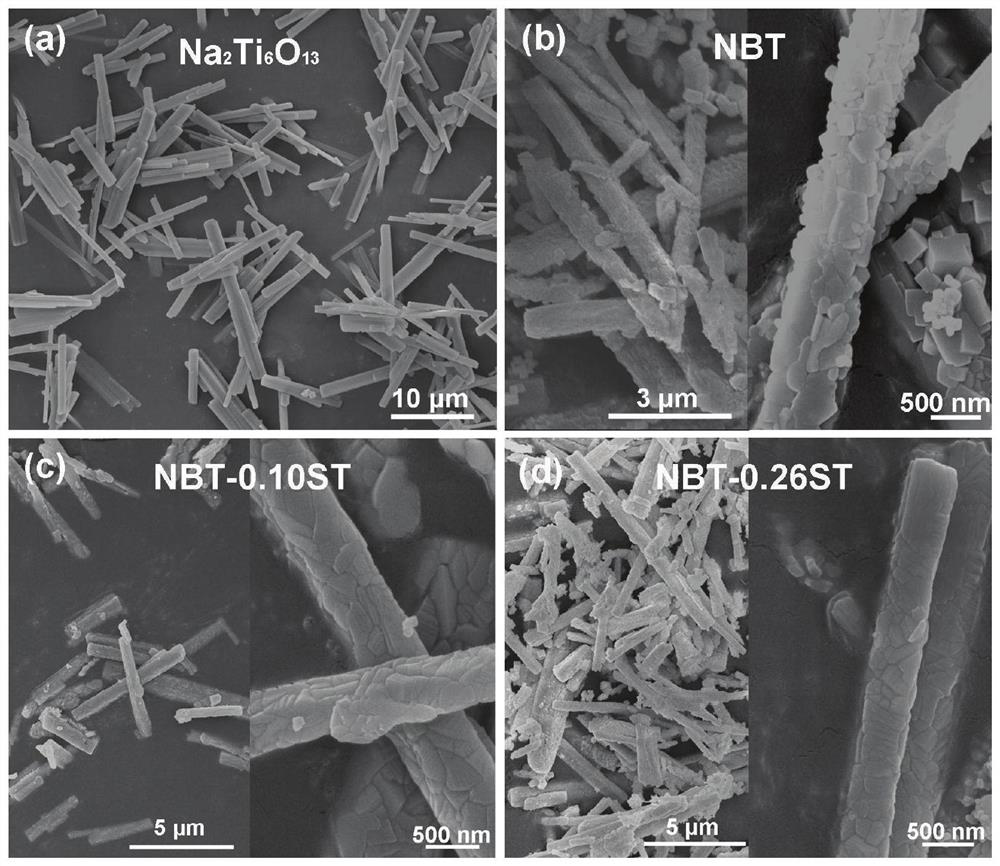

[0122] The first step of molten salt method to prepare Na 2 Ti 6 o 13 Single crystal submicron rods:

[0123] Weigh 2.650g Na 2 CO 3 Powder, 11.975g TiO 2 Powder and 29.250g NaCl powder, using absolute ethanol as the medium, wet ball milling for 24h, after uniform mixing, drying, sieving powder, putting the mixed powder in an alumina crucible, and raising the temperature to 1050°C at a rate of 5°C / min (sintering temperature), heat preservation 2 hours, after heat preservation time finishes, naturally cool to room temperature. The obtained product was soaked in deionized water, suction filtered, cleaned, and then dried in a drying oven at 80°C to obtain Na 2 Ti 6 o 13 Single crystal submicron rods.

Embodiment 2

[0125] Preparation of NBT polycrystalline submicron rods by molten salt method in the second step:

[0126] Weigh 2.710g Na 2 Ti 6 o 13 Single crystal submicron rod (made in embodiment 1), 0.265g Na 2 CO 3 Powder, 3.495gBi 2 o 3 Powder and 12.940g NaCl powder, with absolute ethanol as the medium, magnetically stirred for 6h, after uniform mixing, dried, sieved, put the mixed powder in an alumina crucible, and raised the temperature to 900°C at a rate of 5°C / min , heat preservation for 6 hours, after the heat preservation time is over, cool down to room temperature naturally. The obtained product was soaked in deionized water, suction filtered, washed, and then dried in a drying oven at 80° C. to obtain NBT polycrystalline submicron rods.

Embodiment 3

[0128] The second step is to prepare NBT-0.10ST polycrystalline submicron rods by molten salt method:

[0129] Weigh 2.435g Na 2 Ti 6 o 13 Single crystal submicron rod (made in embodiment 1), 0.239g Na 2 CO 3 Powder, 3.145gBi 2 o 3 Powder, 0.443g SrCO 3 Powder, 0.240g TiO 2 Powder and 13.003g NaCl powder, with absolute ethanol as the medium, magnetically stirred for 6h, after uniform mixing, dried, sieved, put the mixed powder in an alumina crucible, and raised the temperature to 900°C at a rate of 5°C / min. Keep warm for 2 hours, and cool down to room temperature naturally after the heat preservation time is over. The obtained product was soaked in deionized water, suction filtered, washed, and then dried in a drying oven at 80° C. to obtain NBT-0.10ST polycrystalline submicron rods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com