Mite-killing, degerming and deodorizing polyurethane foam material and preparation technology thereof

A foaming material and polyurethane technology, applied in the field of sterilizing, sterilizing and deodorizing polyurethane foam materials and their preparation, can solve the problem that the sterilization and mites cannot be fundamentally eliminated, the effect maintenance time is short, and the efficiency of sterilizing and sterilizing is low. and other problems, to achieve the effect of removing odor, simple steps and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a kind of polyurethane foaming material for killing acarids, degerming and deodorizing, which is mainly prepared from the following raw materials in parts by mass: 900 parts of polyether polyol, 650 parts of diphenylmethane diisocyanate, dimethyl 20 parts of ethanolamine, 50 parts of water, 10 parts of silicone oil, 2 parts of dibutyltin dilaurate, 3 parts of dimethylethanolamine, 100 parts of activated carbon, 5 parts of nano-titanium dioxide, 5 parts of azadirachtin, and 5 parts of spirulina.

Embodiment 2

[0068] This embodiment provides a kind of polyurethane foam material for killing acarids, degerming and deodorizing, which is mainly prepared from the following raw materials in parts by mass: 1000 parts of polyether polyol, 450 parts of ethylene diisocyanate, N-methyl diisocyanate 100 parts of ethanolamine, 40 parts of water, 80 parts of silicone oil, 3 parts of stannous oxalate, 8 parts of triethyldiamine, 30 parts of activated carbon, 100 parts of nano-titanium dioxide, 25 parts of azadirachtin, and 25 parts of spiromitin.

Embodiment 3

[0070] This embodiment provides a kind of polyurethane foam material for killing acarids, degerming and deodorizing, which is mainly prepared from the following raw materials in parts by mass: 920 parts of polyether polyol, 600 parts of toluene isocyanate, 40 parts of triethanolamine, water 48 parts, 30 parts of silicone oil, 3 parts of stannous octoate, 4 parts of dialkylpiperazine, 80 parts of activated carbon, 60 parts of nano-titanium dioxide, 20 parts of azadirachtin, and 20 parts of spirulina.

PUM

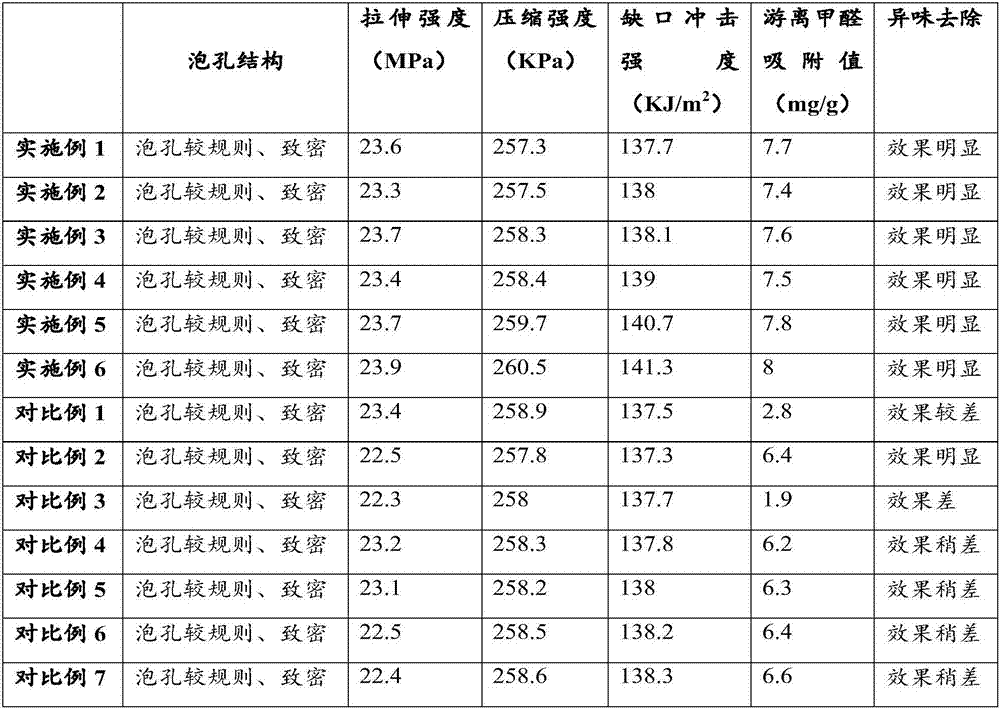

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com