Environment-friendly waterborne sliced rock paint for coating external walls of buildings and preparation method thereof

An environmentally friendly technology for building exterior walls, applied in the field of decorative paint, can solve the problems of complicated preparation process, heavy weight, and many raw materials used, and achieve the effect of simple production process, superior product performance, and realistic stone-like effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

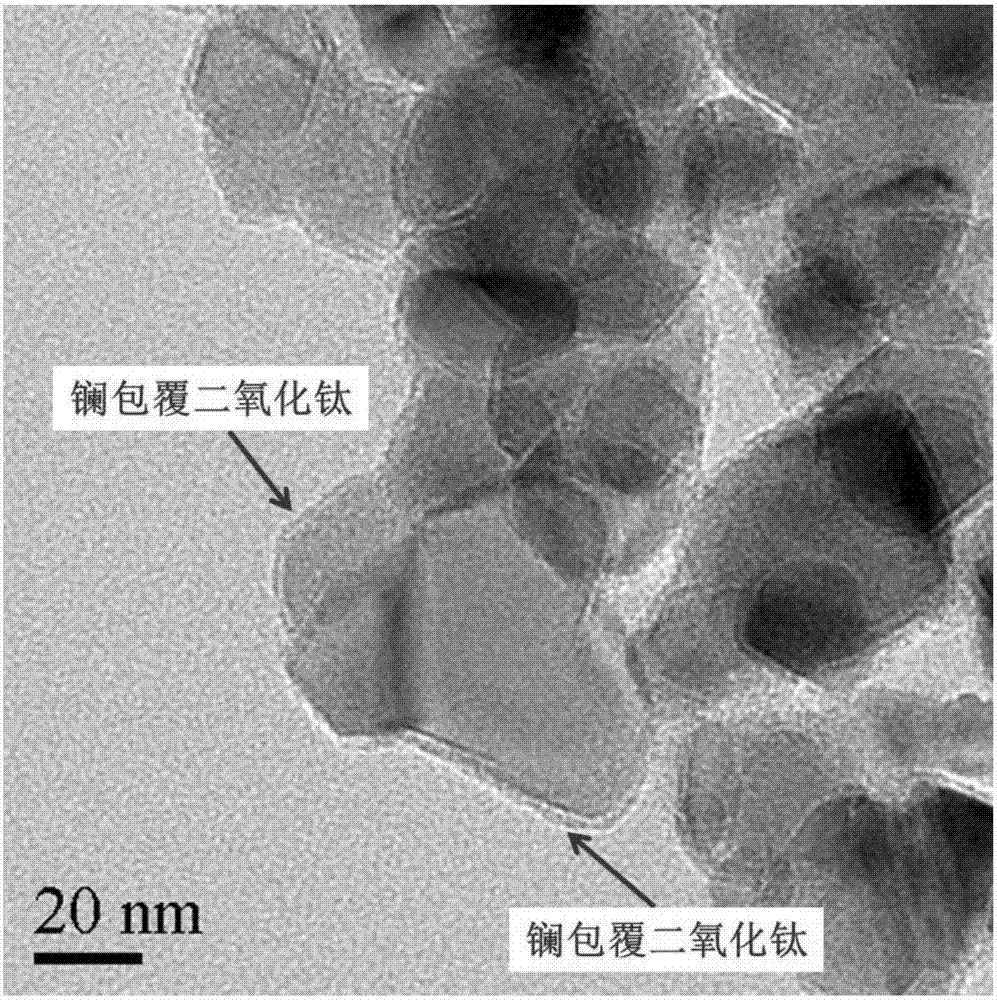

[0033] First, add distilled water, rare earth element compound and titanium source P25 into the reaction kettle in a certain proportion, wherein the mass ratio of distilled water, lanthanum nitrate and titanium source P25 is 1000:1:20, and then stir at a speed of 1000 rpm After 15 minutes, a white suspension dispersion was formed. After hydrothermally treating the above reaction kettle at 180°C for 8-10 hours, suction filtration, washing and roasting at 600°C for 5 hours, the rare earth element-coated nano-titanium dioxide can be obtained. Such as figure 1 shown. Secondly, calculated by weight, add water 35%, wetting agent 0.1%, defoamer 0.4%, multifunctional auxiliary agent 0.2%, film-forming auxiliary agent 3%, emulsion 35%, rare earth element package Coated with nano-titanium dioxide (that is, functional particles) 5%, natural rock slices 20%, thickener 1%, and bactericidal preservative 0.3%. After stirring for 30 minutes, an environmentally friendly water-based rock fla...

Embodiment 2

[0035] First, add distilled water, rare earth element compound and titanium source P25 into the reaction kettle in a certain proportion, wherein the mass ratio of distilled water, lanthanum nitrate and titanium source P25 is 1000:2:20, and then stir at a speed of 1000 rpm After 15 minutes, a white suspension dispersion was formed. After hydrothermally treating the above reaction kettle at 180°C for 8-10 hours, suction filtration, washing and roasting at 600°C for 5 hours, the rare earth element-coated nano-titanium dioxide can be obtained. Secondly, calculated by weight, add water 35%, wetting agent 0.1%, defoamer 0.4%, multifunctional auxiliary agent 0.2%, film-forming auxiliary agent 3%, emulsion 35%, rare earth element package Coated with nano-titanium dioxide (that is, functional particles) 5%, natural rock slices 20%, thickener 1%, and bactericidal preservative 0.3%. After stirring for 30 minutes, an environmentally friendly water-based rock flake paint can be obtained, ...

Embodiment 3

[0037] First, add distilled water, rare earth element compound and titanium source P25 into the reaction kettle in a certain proportion, wherein the mass ratio of distilled water, rare earth element compound and titanium source P25 is 1000:2:20, and the rare earth element compound is lanthanum nitrate and nitric acid Cerium was obtained by mixing at a mass ratio of 1:1, and then stirred at a speed of 1000 rpm for 15 minutes to form a white suspension dispersion. After hydrothermally treating the above reaction kettle at 180°C for 8-10 hours, suction filtration, washing and roasting at 600°C for 5 hours, the rare earth element-coated nano-titanium dioxide can be obtained. Secondly, calculated by weight, add water 35%, wetting agent 0.1%, defoamer 0.4%, multifunctional auxiliary agent 0.2%, film-forming auxiliary agent 3%, emulsion 35%, rare earth element package Coated with nano-titanium dioxide (that is, functional particles) 5%, natural rock slices 20%, thickener 1%, and bact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com