A kind of heavy oil well wellbore viscosity reduction test device and method

A test method and wellbore technology are applied in the process optimization of the viscosity reducer for heavy oil wells and the field of viscosity reduction test devices for heavy oil wells, which can solve the problems of lack of theoretical basis, low accuracy and reliability, and achieve a high degree of simulation. , Simple structure, improve the effect of on-site application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

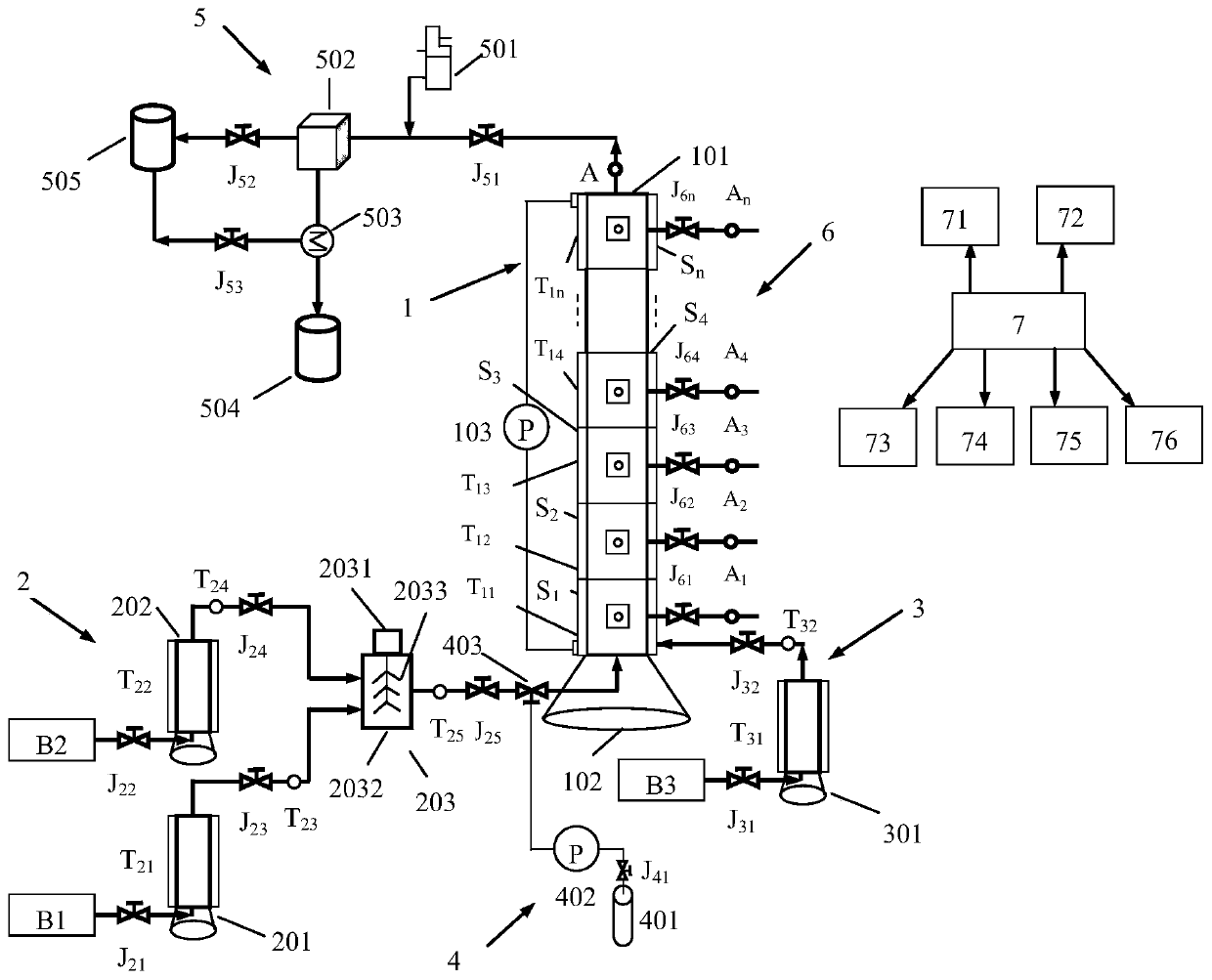

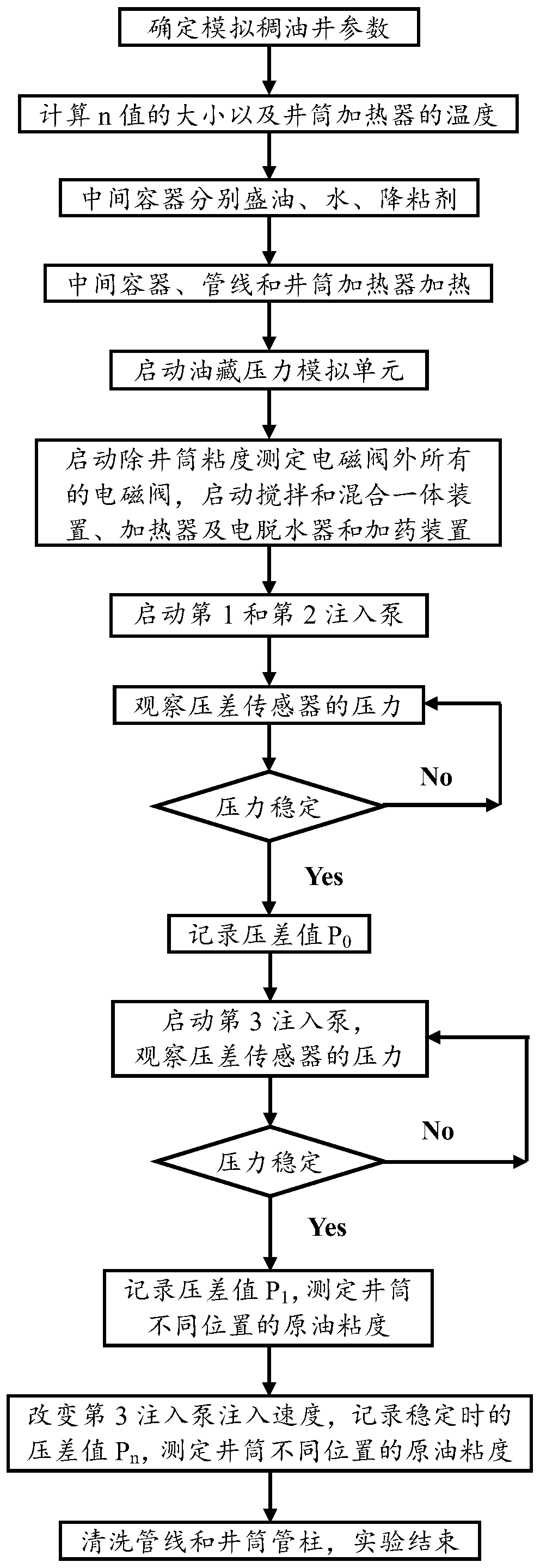

Method used

Image

Examples

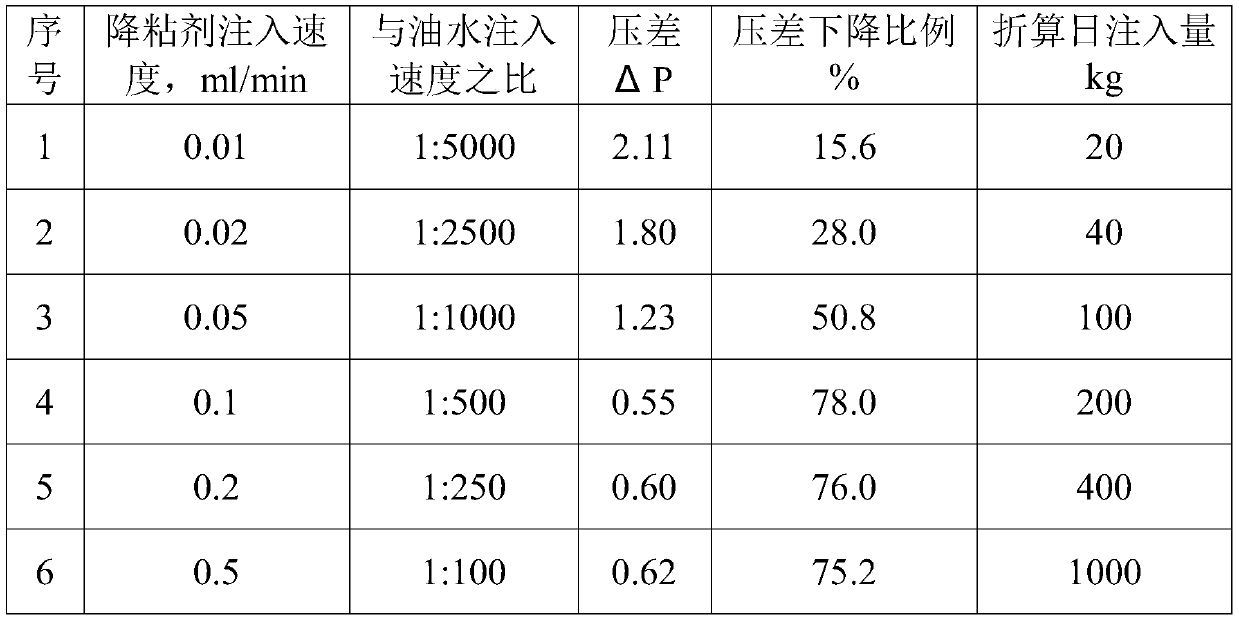

Embodiment 1

[0063] CD of a heavy oil well in a block of Shengli Oilfield 11 , Oil layer pressure 10.5MPa, oil layer temperature 56℃, surface crude oil viscosity 8560mPa.s, well depth 525m, produced fluid water content 80% (oil-water ratio 1:4), daily fluid production is 100m 3 , It is planned to use heavy oil viscosity reducer to reduce the viscosity of the wellbore. The mass concentration of the heavy oil viscosity reducer is 20%. Before field implementation, the device and method of the present invention are used to optimize the dosage of the heavy oil viscosity reducer. Specific steps are as follows:

[0064] (1) Determine CD of simulated heavy oil well 11 Parameters such as oil layer pressure, temperature, well depth and produced fluid water cut.

[0065] The oil layer pressure is 10.5MPa, the oil layer temperature is 56°C, the well depth is 525m, and the produced fluid contains 80% water (oil-water ratio 1:4).

[0066] (2) Determine the value of n according to the depth of the simulated he...

Embodiment 2

[0090] CD of a heavy oil well in a block of Shengli Oilfield 32 , Oil layer pressure 9.2MPa, oil layer temperature 90℃, surface crude oil viscosity 9256mPa.s, well depth 980m, produced fluid water content 90% (oil-water ratio 1:9), daily fluid production volume is 120m 3 It is planned to use heavy oil viscosity reducer to reduce the viscosity of the wellbore. The mass concentration of the heavy oil viscosity reducer is 25.0%. Before field implementation, the device and method of the present invention are used to optimize the dosage of the heavy oil viscosity reducer. Specific steps are as follows:

[0091] (1) Determine CD of simulated heavy oil well 32 Parameters such as oil layer pressure, temperature, well depth and produced fluid water cut.

[0092] The oil layer pressure is 9.2MPa, the oil layer temperature is 90°C, the well depth is 980m, and the produced fluid contains 90% water (oil-water ratio 1:9).

[0093] (2) Determine the value of n according to the depth of the simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com