Method for quantitatively determining content of cuprous oxide in corrosion products of copper

A technology for corrosion products and cuprous oxide, which is applied in the direction of chemical analysis by titration, and can solve the problems of inability to accurately measure the content of cuprous oxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

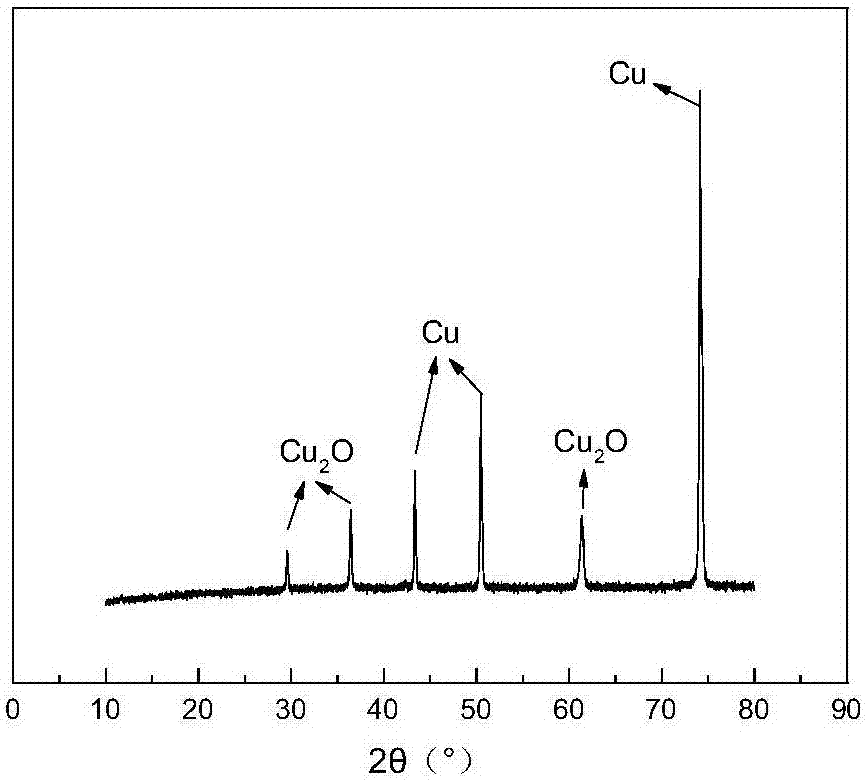

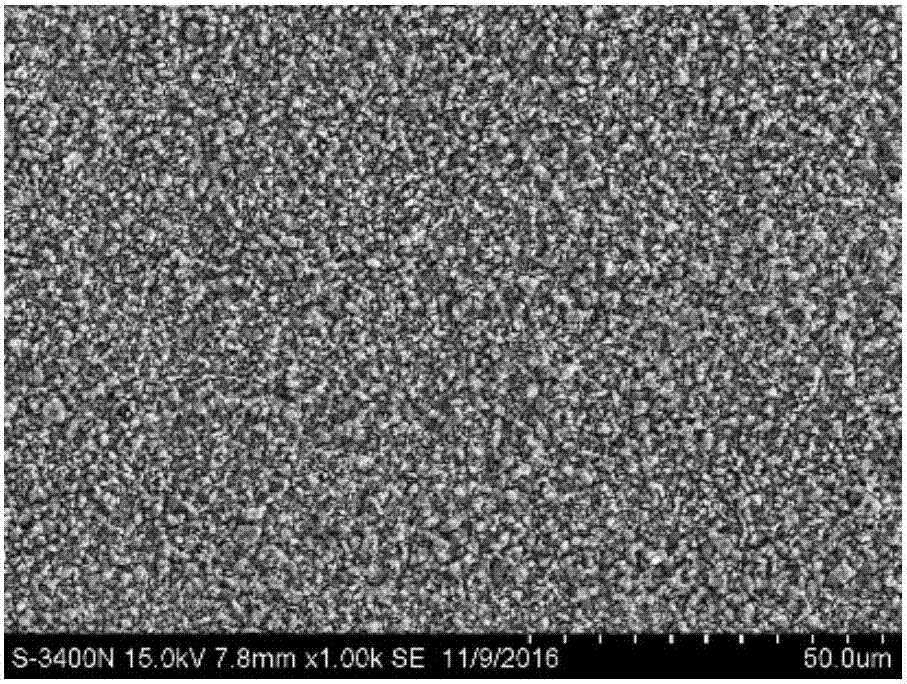

[0025] Quickly prepare a rusted copper sheet sample with only cuprous oxide on the surface: polish a pure copper sheet with a size of 25mm×10mm×1mm to 3000 mesh with SiC polishing paper, and then polish it to 1 μm with a diamond abrasive. Put the polished pure copper sheet into the boiling saturated copper sulfate solution and let it stand for 1 hour, then rinse it with deionized water, take out the corroded copper sample from the copper sulfate solution, and ultrasonically vibrate the front and back of the corroded copper sheet 20s removes the copper sulfate reagent sticking to the surface, then repeatedly rinses with deionized water, and dries to make a uniform and dense cuprous oxide film on the surface of the copper sheet (see figure 2 , image 3 ). Weigh the mass of the rusted copper sheet to be 3.961267g

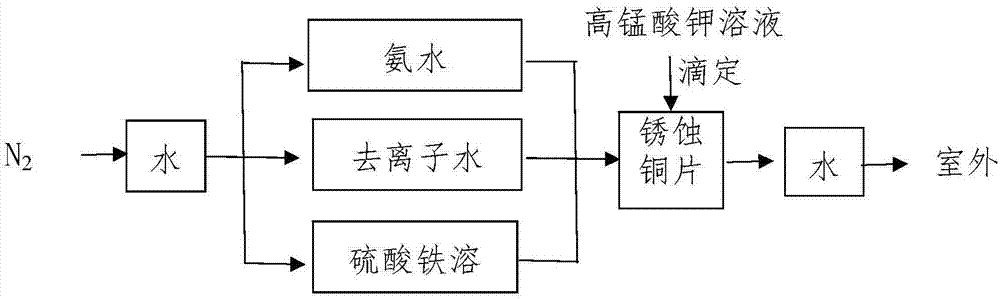

[0026] according to figure 1 Process shown:

[0027] 1) Dissolution of corrosion products on the surface of the rusted copper sheet: use high-purity nitrogen (99....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com