Eutectic soldering process method of microwave chip

A technology of eutectic welding and microwave chips, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of not being suitable for the production of small batches, multi-variety modules, and high purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

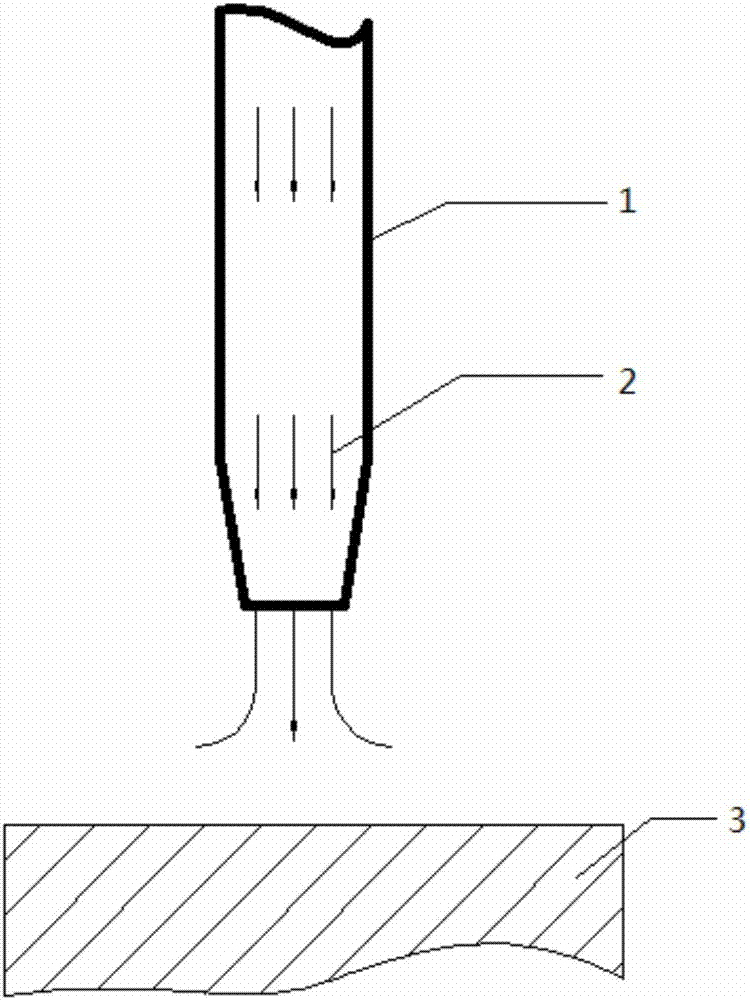

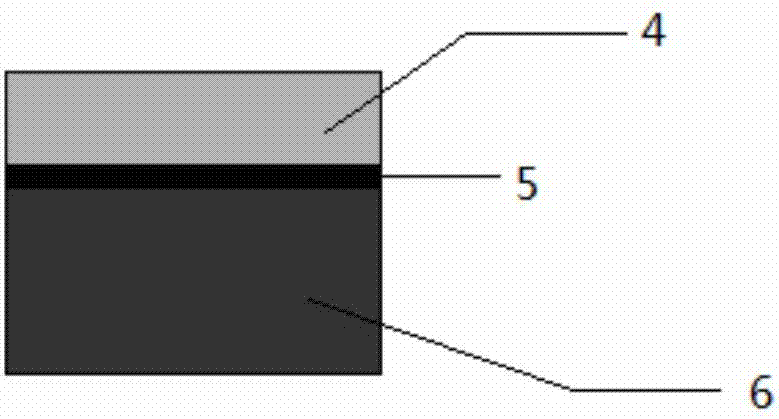

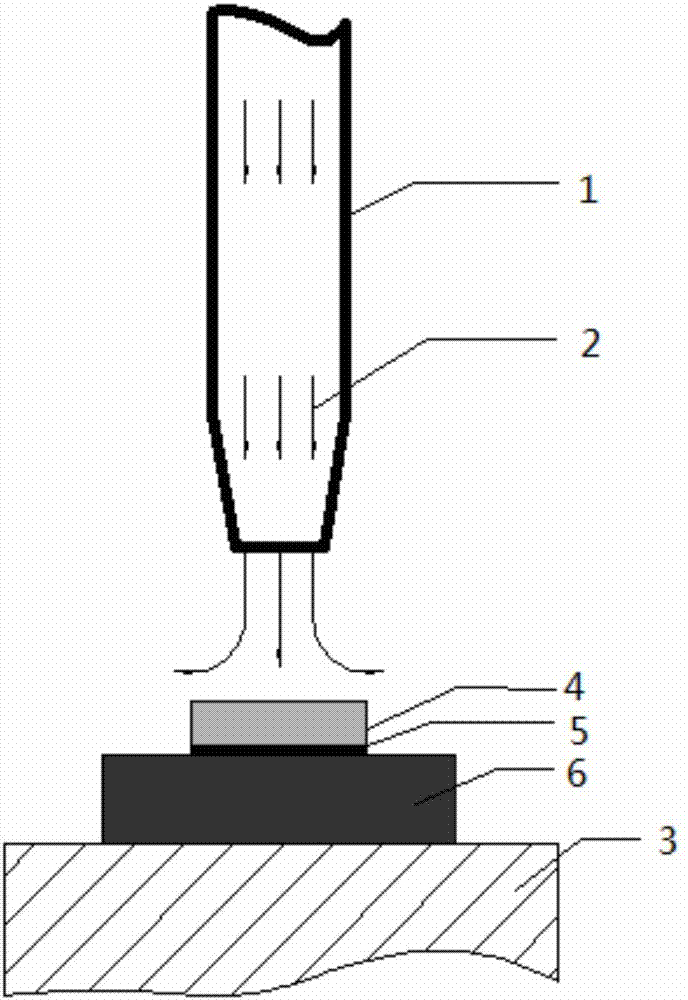

[0054]as attached figure 2 shown, with figure 2 It is a schematic diagram of microwave chip eutectic, carrier size specification: 4*8*0.2mm, preform size specification: 4*3.2*0.0254mm, chip size specification: 4*3.2*0.10mm; attached image 3 It is a schematic diagram of the microwave chip eutectic bonding process in Example 1. The specific implementation steps are as follows:

[0055] Step 1. Cleaning and drying of the carrier: put the carrier into an anhydrous ethanol solution, soak for 10 minutes, and then wipe the surface of the carrier (welding surface) with an absorbent cotton ball; then put the carrier into an oven at a temperature of 80-100°C , bake for 10 minutes;

[0056] Step 2. Plasma cleaning of the carrier: put the carrier in the previous step into a plasma cleaning machine for cleaning, and use argon gas for cleaning. The plasma cleaning power is: 500W, and the time: 15 minutes.

[0057] Step 3. Set the eutectic welding parameters:

[0058] The welding par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com