Large-aspect-ratio magnetic shaft structure of shaft type linear motor

A linear motor, large aspect ratio technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of the complex assembly process of the radially magnetized magnetic steel single body of the ring magnet, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

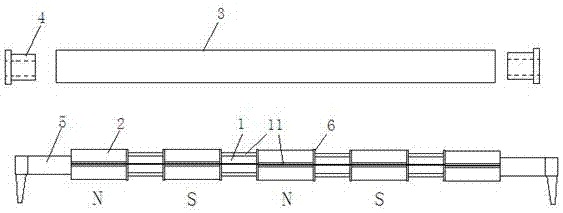

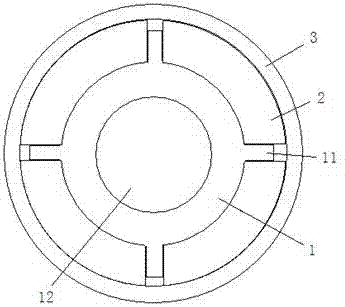

[0026] Such as figure 1 , figure 2As shown, the present invention includes a cross hollow shaft 1, a fan-shaped radial magnetic tile 2, a stainless steel sleeve 3 and an end cover 4. The cross hollow shaft 1 is a symmetrically raised axial rib 11 on the outer peripheral surface of the hollow circular shaft. structure, the outer peripheral surface of the cross hollow shaft 1 is axially connected to the fan-shaped radial magnetic tiles 2 at intervals, and each section is connected by four fan-shaped radial magnetic tiles 2 inner arc walls on the axial peripheral surface between two ribs 11, and the adjacent sections The magnetic tile is a heterogeneous magnetic tile, and the fan-shaped radial magnetic tile 2 is connected into one body and set in the casing 3. The two ends of the hollow cavity of the cross hollow shaft 1 are connected to the water pipe head 5 to form a cooling water channel 12. The water pipe head 5 passes through the end. The cover 3 is snapped and fixed.

...

Embodiment 2

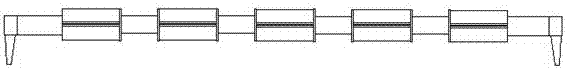

[0030] Such as image 3 As shown, the ribs on the outer peripheral surface of the cross hollow shaft between the two sections of magnetic tiles are removed, and a spacer is connected to the cross hollow shaft at the end of each section of magnetic tile. There is a ring groove, and the ring-shaped spacers are clamped and bonded in the ring groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com