Novel frame-structure hydropress technical field

A frame structure and hydraulic press technology, applied in the field of hydraulic presses, can solve the problems of high labor intensity of workers and large production line pressure, and achieve the effects of improving production efficiency, speeding up production speed, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

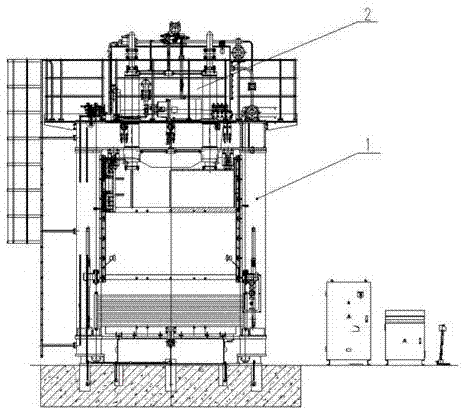

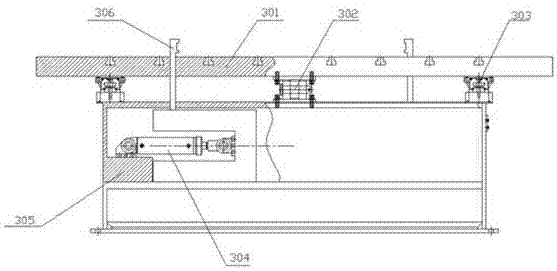

[0050] like figure 1 , figure 2 As shown in , a novel frame structure hydraulic machine, including a foundation, a fuselage 1 and a hydraulic system 2; the fuselage 1 is installed on the foundation, and the fuselage 1 includes a mobile workbench 3; the hydraulic system 2 is installed on the top of the fuselage 1, The hydraulic system 2 includes a hydraulic pump and a motor; the hydraulic pump is an inclined-axis plunger pump; the power of the motor is 30kw; the mobile workbench 3 includes a base 305, a mobile device and a quick clamping device; the mobile device includes a positioning hydraulic control system, a mold Base plate 301, first oil cylinder 302 and linear guide rail pair 303; Linear guide rail pair 303 is strip guide rail, quantity is two, is arranged between base 305 and mold base plate 301 in parallel, the distance of linear guide rail pair 303 and base 305 side The linear guide rail pair 303 is divided into an upper guide rail and a lower guide rail; the upper ...

Embodiment 2

[0068] The device in this embodiment is the same as that in Embodiment 1, except that there is one threaded hole on the upper surface of the sliding body; the distance between the linear guide pair 303 and the side of the base 305 is 30 mm.

[0069] In this embodiment, the method of using a novel frame structure hydraulic press needs to replace the mold three times, and the steps are the same as in Embodiment 1, except that:

[0070] G replace the third mold, the steps are as follows:

[0071] 1) Place the third mold on the mold bottom plate 301 and adjust its orientation.

[0072] 2) Take back the mold bottom plate 301, output an electric signal through the controller 34, and transmit it to the proportional valve 32 through the amplifier 33, and the second oil port of the proportional valve 32 is opened to input pressure oil to the oil outlet of the first oil cylinder 302, and the proportional valve 32 The first oil port is opened to receive the oil flowing back from the oil...

Embodiment 3

[0077] The device in this implementation is the same as that in Embodiment 1, the difference is that there are 8 threaded holes on the upper surface of the sliding body; the distance between the linear guide pair 303 and the side of the base 305 is 50 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com