Rapidly started self-heating type micro-reactor for producing hydrogen by reforming methanol

A reforming hydrogen production, quick start technology, applied in the directions of hydrogen, combustion type, lighting and heating equipment, etc., to achieve the effects of low processing cost, improved combustion efficiency and catalyst life, and high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

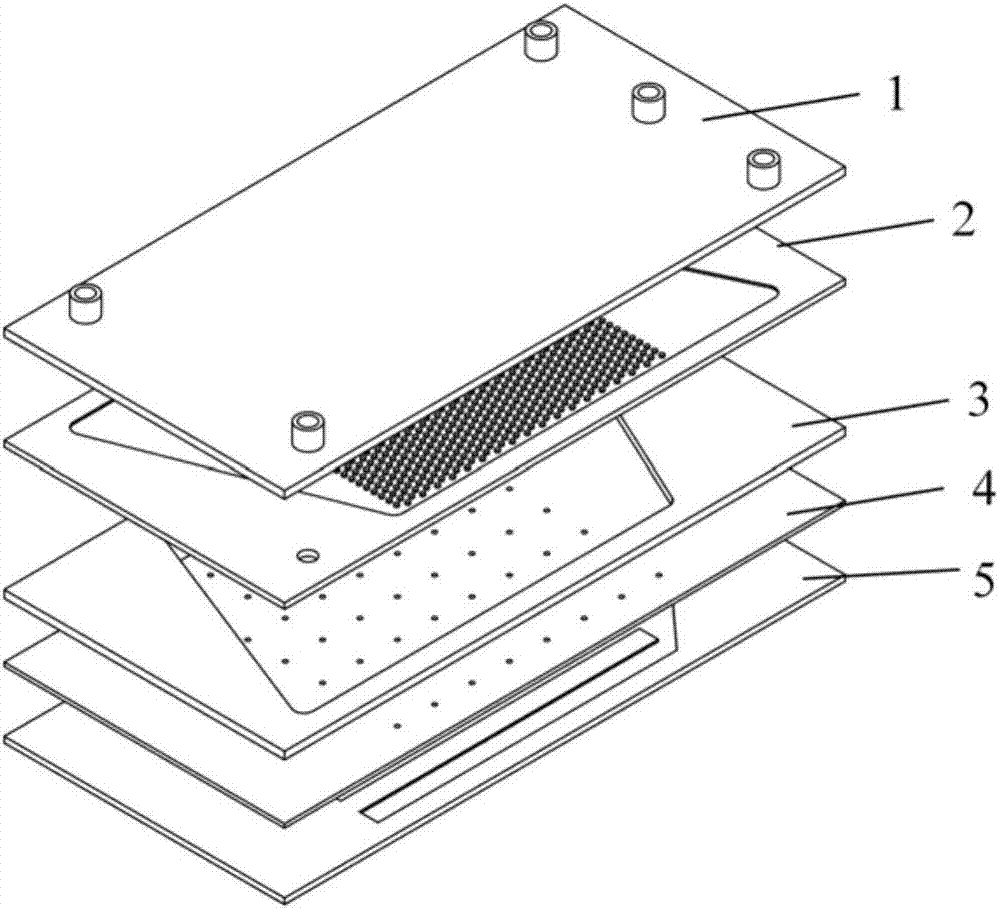

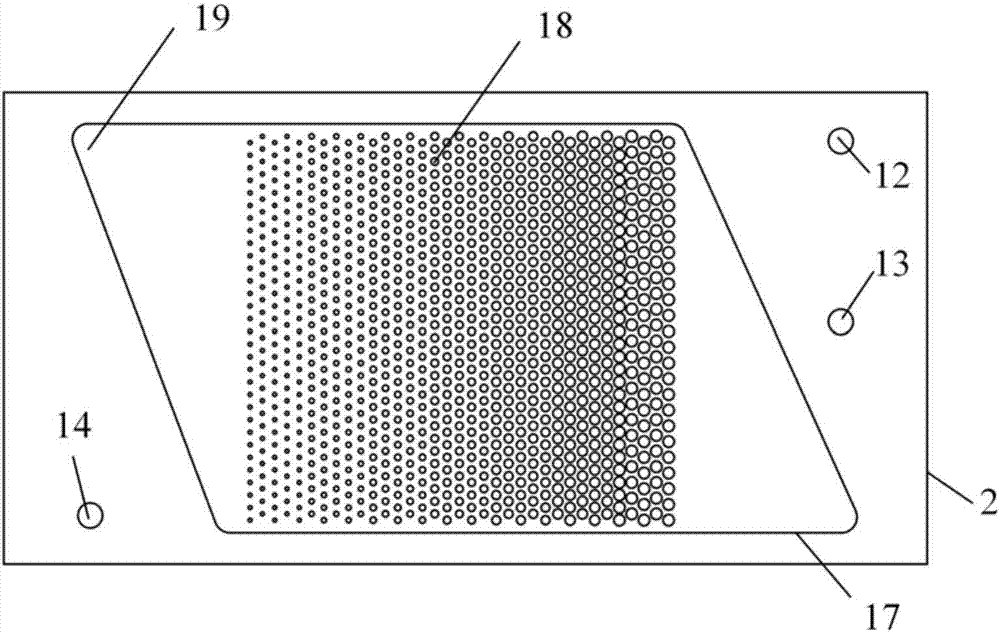

[0035] A kind of rapid start self-heating type methanol reforming hydrogen production micro-reactor of the present embodiment, such as Figure 1-7 As shown, from top to bottom, it is composed of cover plate assembly 1, reforming hydrogen production plate 2, first methanol combustion plate 3, methanol combustion porous plate 4, and second methanol combustion plate 5; and the cover The plate assembly 1, the reforming hydrogen production plate 2, the first methanol combustion plate 3, the methanol combustion porous plate 4, and the second methanol combustion plate 5 are respectively rectangular structures of equal size; wherein:

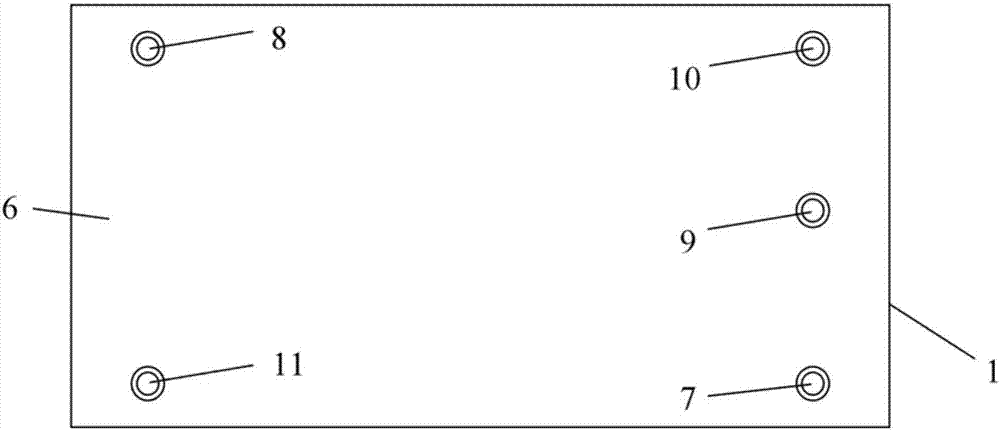

[0036] The cover plate assembly 1 includes a rectangular upper cover plate 6, and the rectangular upper cover plate 6 is equipped with a reformed fuel inlet stainless steel pipe 7, a reformed fuel outlet stainless steel pipe 8, a methanol inlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com