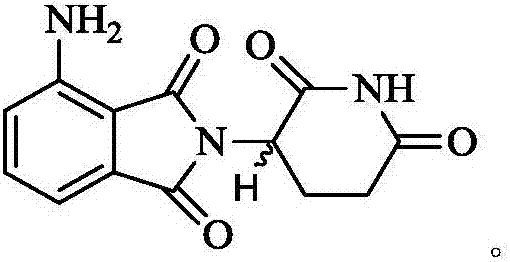

Preparation method of pomalidomide

A technology for pomalidomide and a compound is applied in the field of preparation of anticancer drug pomalidomide, which can solve the problems of numerous steps, complicated operation, and difficulty in realizing industrialized production, and achieves reduction of production cost, short synthesis route and raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

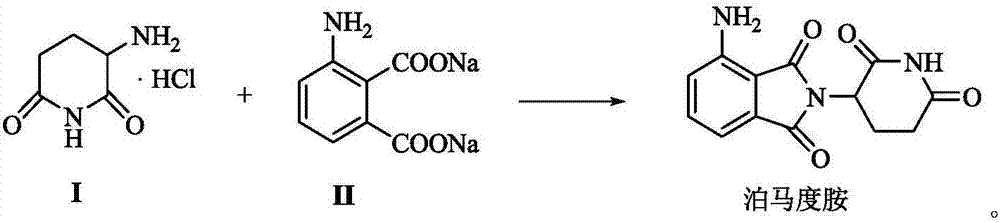

Method used

Image

Examples

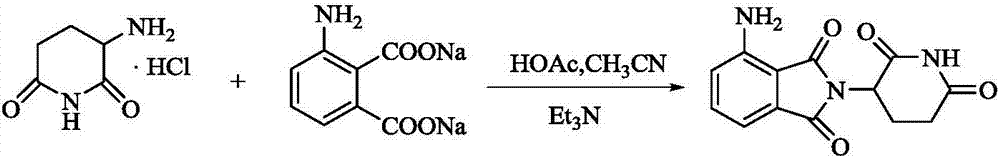

Embodiment 1

[0020]

[0021] Acetonitrile (100 mL), acetic acid (25.41 mL, 444.2 mmol), triethylamine (22.48 g, 222.1 mmol), disodium 3-aminophthalate (10 g, 44.4 mmol), 3-aminopiperidine-2, Add 6-diketone hydrochloride (7.68g, 46.6mmol) into the reaction flask, heat to 80-85°C and reflux. After 6 hours of reaction, the reaction is complete. Cool the reaction solution to 20-25°C, slowly add purified water, stir and analyze Crystallized for 2 hours, filtered, and the filter cake was dried under reduced pressure at 60±5°C for 8 hours to obtain 8.98 g of a black solid with a yield of 74.0% and a purity of 99.1%.

Embodiment 2

[0023] Acetonitrile (100 mL), acetic acid (25.41 mL, 444.2 mmol), triethylamine (12.62 mL, 88.8 mmol), disodium 3-aminophthalate (10 g, 44.4 mmol), 3-aminopiperidine-2, Add 6-diketone hydrochloride (7.68g, 46.6mmol) into the reaction flask, heat to 80-85°C to reflux, react for 8 hours, cool the reaction solution to 20-25°C, slowly add purified water, stir and crystallize for 2 hours , filtered, and the filter cake was dried under reduced pressure at 60±5° C. for 8 hours to obtain 8.9 g of yellow solid, yield: 73.3%, purity: 99.2%. Example 3

Embodiment 3

[0024] Acetonitrile (100mL), acetic acid (25.41mL, 444.2mmol), anhydrous sodium acetate (18.22g, 222.1mmol), disodium 3-aminophthalate (10g, 44.4mmol), 3-aminopiperidine-2 , Add 6-diketone hydrochloride (7.68g, 46.6mmol) into the reaction flask, heat to 80-85°C to reflux, react for 8 hours and complete the reaction, cool the reaction solution to 20-25°C, slowly add purified water, stir Crystallize for 2 hours, filter, and dry the filter cake under reduced pressure at 60±5°C for 8 hours to obtain 10.2 g of a yellow solid with a yield of 84.0% and a purity of 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com