Copper metal organic framework material with supercapacitor performance as well as preparation method and application thereof

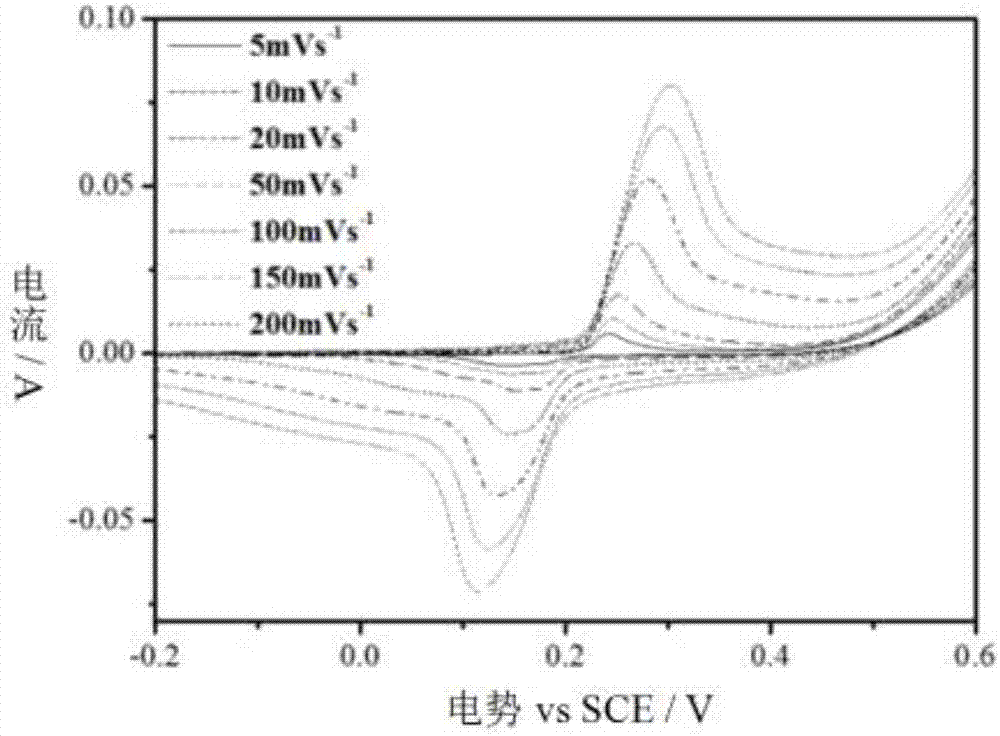

An organic framework and supercapacitor technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited application of MOFs materials and limited specific capacitance, so as to enhance the ability to store charges and improve specific capacitance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

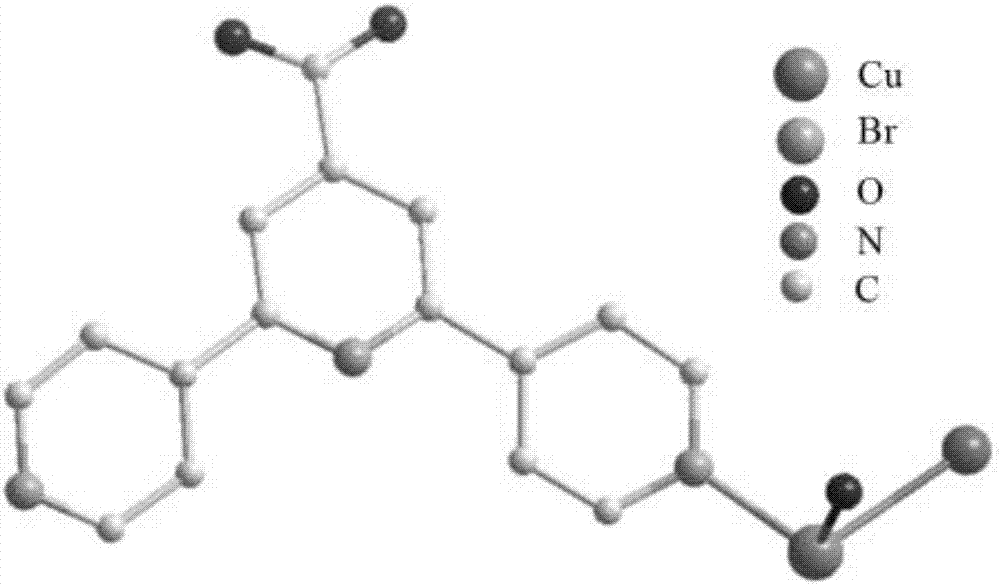

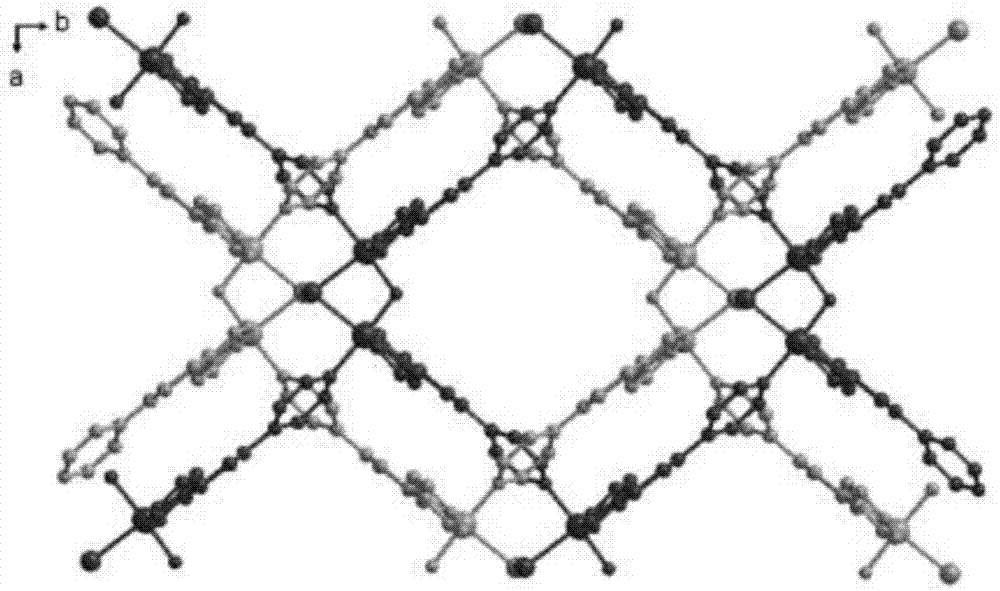

[0034] Weigh 5 mg of 4,2′:6′,4″-tripyridine-4′-benzoic acid (commercially available, produced by Jinan Henghua Reagent Co., Ltd.) and 10 mg of copper nitrate into the reaction flask, and add 4 mL of methanol Solution, the reaction bottle was ultrasonicated for 10 minutes, and the pH of the solution was adjusted to 7 with 0.1moL / L NaOH solution, put into a stainless steel reaction kettle and placed in an oven. The reaction temperature was 130°C, and the time was 48 hours. ℃, the product obtained is green crystal particles, and the crystals are separated and separated by cooling and filtration. Finally, the crystals are washed and dried to obtain a copper metal organic framework material with supercapacitive properties, with a yield of 60%.

Embodiment 2

[0036]Weigh 5 mg of 4,2′:6′,4″-tripyridine-4′-benzoic acid (commercially available product, produced by Jinan Henghua Reagent Co., Ltd.) and 9 mg of copper nitrate into the reaction flask, and add 5 mL of methanol Solution, the reaction bottle was ultrasonicated for 12min, and the pH of the solution was adjusted to 7.2 with 0.09moL / L NaOH solution, put into a stainless steel reaction kettle and placed in an oven. The reaction temperature was 110°C, and the time was 60 hours. ℃, the obtained product is a large amount of green flocculent precipitate and a small amount of green crystal particles, the crystals are separated and separated by cooling and filtration, and finally the crystals are washed and dried to obtain a copper metal organic framework material with supercapacitive properties, with a yield of 65%.

Embodiment 3

[0038] Weigh 5 mg of 4,2′:6′,4″-tripyridine-4′-benzoic acid (commercially available product, produced by Jinan Henghua Reagent Co., Ltd.) and 11 mg of copper nitrate into the reaction bottle, and add 2.5 mL of Methanol solution, sonicate the reaction bottle for 10min, take it out and adjust the pH of the solution to 6.8 with 0.09moL / L NaOH solution, put it into a stainless steel reaction kettle and put it in an oven. The reaction temperature is 140°C, and the time is 24 hours. Program cooling to At 30°C, the product obtained is a large amount of green flocculent precipitate and a small amount of green crystal particles. The crystals are separated and separated by cooling and filtration. Finally, the crystals are washed and dried to obtain a copper metal organic framework material with supercapacitive properties, with a yield of 62%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com