Engine lubricating oil and preparation method thereof

A lubricating oil and engine technology, applied in the field of lubricating oil, can solve the problems of short oil change mileage, large water and soil pollution, poor shear resistance, etc., and achieve the effect of slight wear, long oil change mileage, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-2

[0072] A preparation method of engine lubricating oil, step 1) raw materials are prepared according to the weight ratio shown in Table 1;

[0073] Step 2) Add VHVI 250N base oil, heat up to 45°C, then add polyol ester, polyα-olefin, alkylnaphthalene, and compounding agent in sequence, and heat up to 55°C at a constant temperature;

[0074] Step 3) Then add organic molybdenum salt, then add calcium salicylate, magnesium sulfonate and boric acid ester in sequence, and stir evenly at a constant temperature of 55°C to obtain lubricating oil for more than 3 hours.

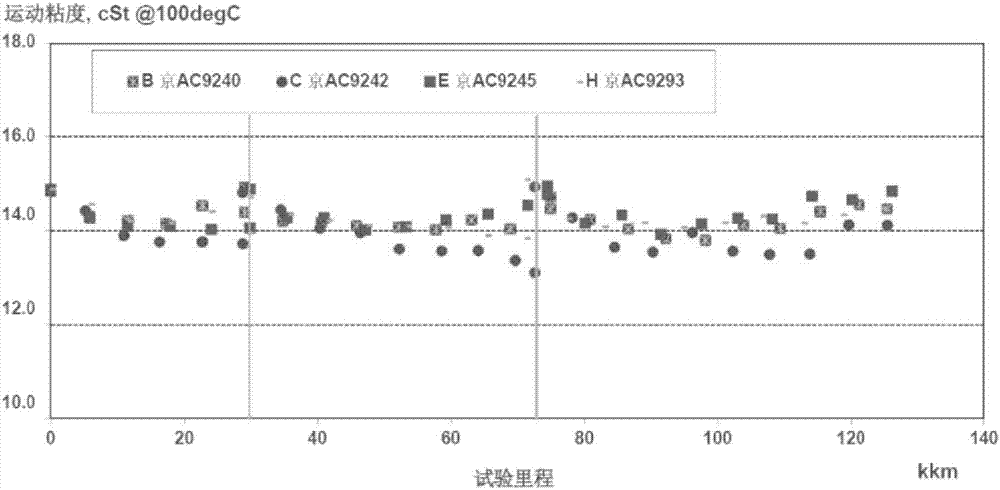

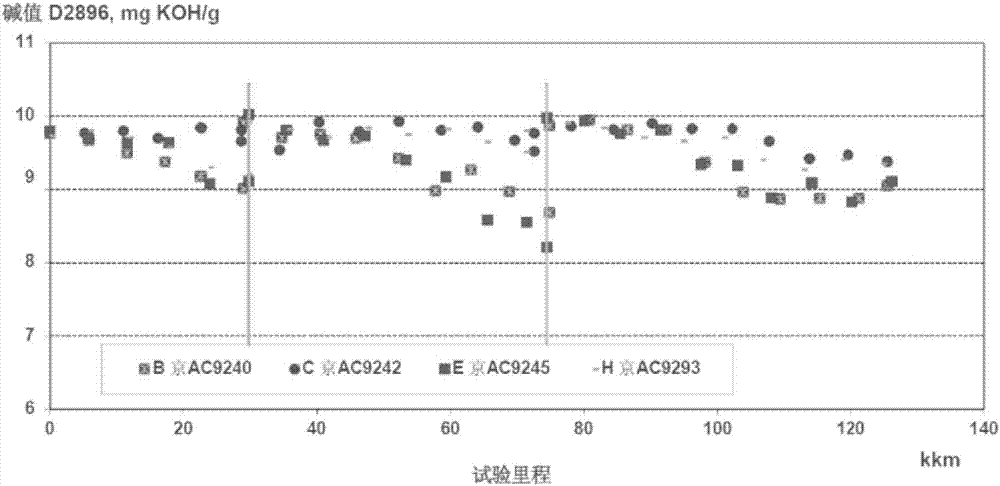

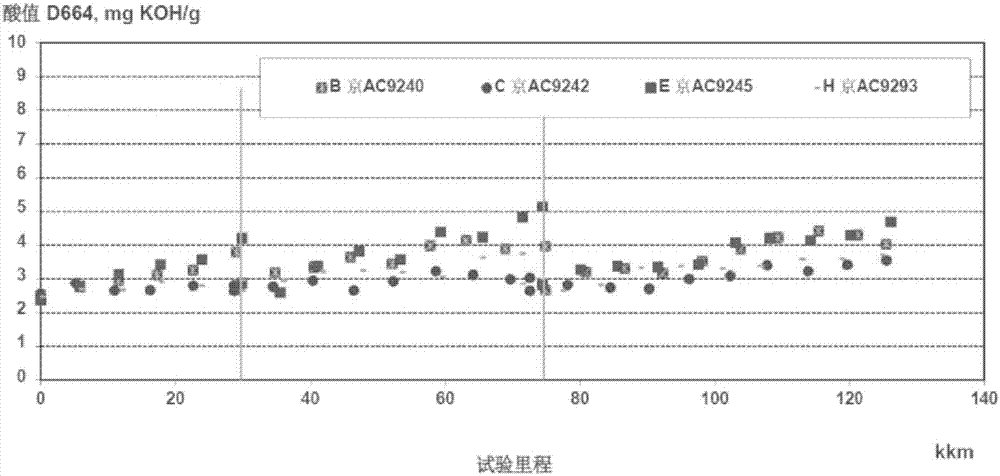

[0075]During the preparation process, the moisture content is strictly controlled to be no more than traces: the micro-content of moisture in the product is tested according to the GB / T 260-1977 (2004) experimental specification. The lubricating oil is subjected to oil change mileage test, old oil analysis and engine wear test, and the test results are listed in Table 2-Table 8.

Embodiment 6

[0107] The invention provides a kind of engine lubricating oil, is made up of following composition by its weight part:

[0108] GTL250N 35.2%;

[0109] Polyalphaolefin PAO4 16.5%;

[0110] Polyalphaolefin PAO150 10.9%;

[0111] Compounding agent Chevron OLOA59110 15%;

[0112] Calcium Salicylate 1.6%;

[0113] Magnesium sulfonate 0.65%;

[0114] Molybdenum salt 0.3%;

[0115] Borate 2.5%;

[0116] Alkylated Naphthalene 7.6%

[0117] Polyol ester 11.75%;

[0118] Among them, the performance grade of Chevron OLOA59110 is CI-4+, and the viscosity quality is 10W-40

[0119] Among them, the kinematic viscosity (KV) of GTL250N at 100°C is 7.6mm 2 / s;

[0120] Low temperature dynamic viscosity (-30°C CCS) is 4020mPa.S.

[0121] The preparation method is:

[0122] Step 1) raw materials are prepared according to weight ratio;

[0123] Step 2) Add VHVI 250N base oil, raise the temperature to 45°C, then add polyol ester, polyα-olefin, alkylnaphthalene, compounding agent in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com