Rare earth-magnesium nodulizing agent

A technology of spheroidizing agent and rare earth magnesium, applied in the field of spheroidizing agent, can solve problems such as increasing the spheroidizing rate, and achieve the effect of increasing the spheroidizing rate and reducing the depth of white mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

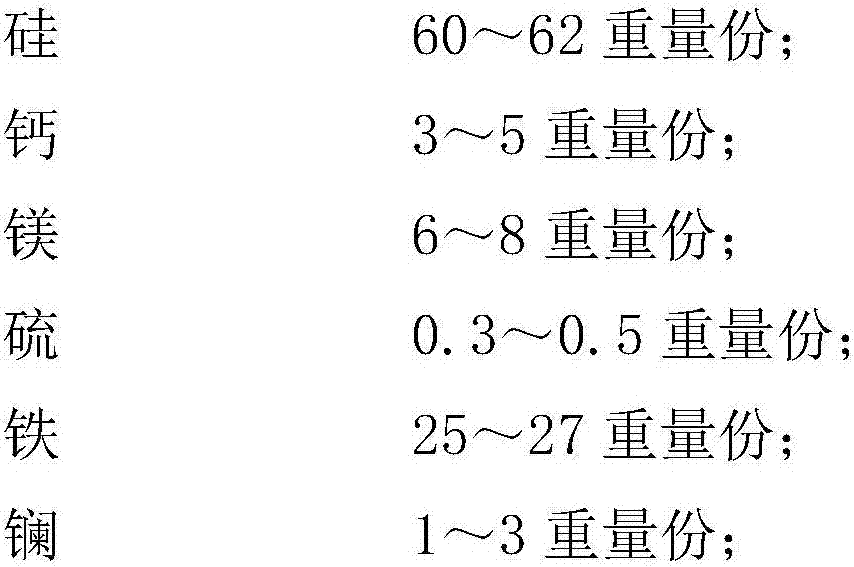

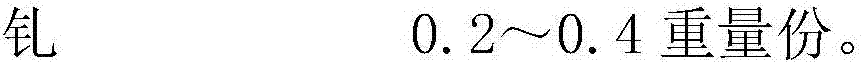

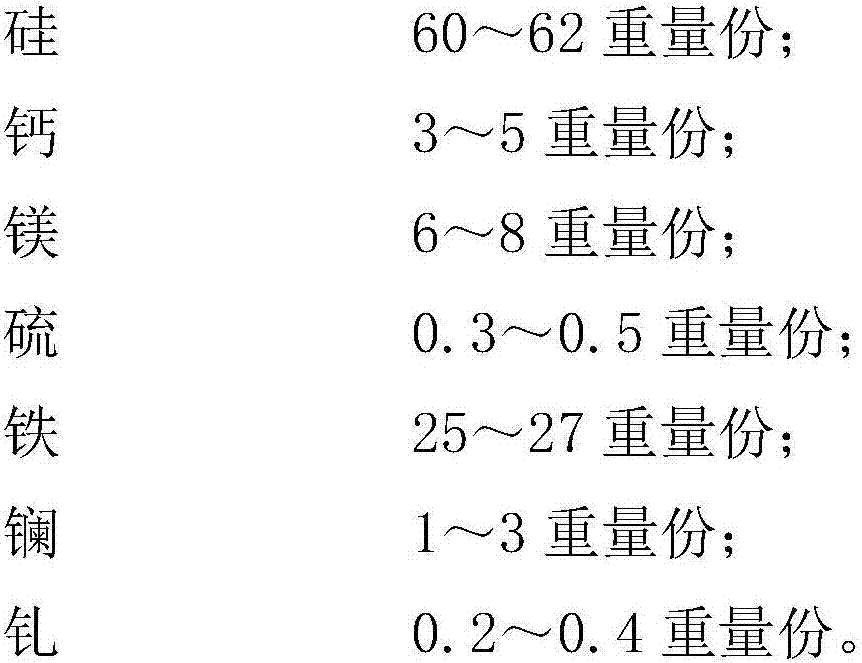

[0016] This case proposes the rare earth magnesium nodulizer of an embodiment, comprises the material of following weight part:

[0017]

[0018] As another embodiment of the present application, 0.5-1.5 parts by weight of barium and 0.05-0.1 parts by weight of molybdenum are further included.

[0019] As yet another embodiment of the present application, 0.05-0.1 parts by weight of cerium is further included.

[0020] As yet another embodiment of the present application, 0.05-0.1 parts by weight of yttrium is further included.

[0021] As yet another embodiment of the present application, 0.005-0.01 parts by weight of rubidium oxide is further included.

[0022] The following table lists the specific composition and performance parameters of different embodiments:

[0023]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com