A small-scale light hydrocarbon gas generation gas production process

A technology for gas generation and light hydrocarbons, applied in combustion methods, combustion equipment, fuel supply, etc., can solve the problems of different gas calorific value, aggravate condensate, easy to produce condensate, etc., achieve stable gas quality, and solve the phenomenon of condensate , the effect of accelerating the volatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

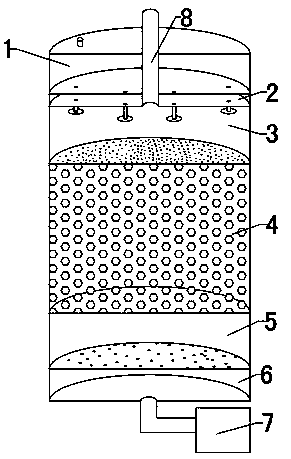

Embodiment 1

[0023] Fill the liquid light hydrocarbon raw material into the light hydrocarbon raw material chamber 1. When it needs to be used, turn on the control switch, the oil delivery booster pump starts to work, and the spray nozzle starts to spray the liquid light hydrocarbon raw material, and the liquid light hydrocarbon raw material is evenly sprinkled on the On the upper dividing plate of the porous ceramic material chamber 4, it enters the porous ceramic material chamber 4 from the pores, and continuously flows downward under the action of gravity to form an oil film on the surface of the porous ceramic material. Controlled by the circuit board, start the hot air blower 7 and start sending hot air 11s after the spray nozzle starts to spray oil. The air supply volume is 1L. The hot air passes through the rectifying chamber 6 and the steady flow chamber 5 successively to form a steadily rising hot air flow. After entering the porous ceramic material chamber 4, the hot air volatili...

Embodiment 2

[0025] Fill the liquid light hydrocarbon raw material into the light hydrocarbon raw material chamber 1. When it needs to be used, turn on the control switch, the oil delivery booster pump starts to work, and the spray nozzle starts to spray the liquid light hydrocarbon raw material, and the liquid light hydrocarbon raw material is evenly sprinkled on the On the upper dividing plate of the porous ceramic material chamber 4, it enters the porous ceramic material chamber 4 from the pores, and continuously flows downward under the action of gravity to form an oil film on the surface of the porous ceramic material. Controlled by the circuit board, start the hot air blower 7 and start sending hot air 15 seconds after the spray nozzle starts to spray oil. The air supply volume is 0.7L. The hot air passes through the rectifying chamber 6 and the steady flow chamber 5 successively to form a steadily rising hot air flow. After entering the porous ceramic material chamber 4, the hot air...

Embodiment 3

[0027]Fill the liquid light hydrocarbon raw material into the light hydrocarbon raw material chamber 1. When it needs to be used, turn on the control switch, the oil delivery booster pump starts to work, and the spray nozzle starts to spray the liquid light hydrocarbon raw material, and the liquid light hydrocarbon raw material is evenly sprinkled on the On the upper dividing plate of the porous ceramic material chamber 4, it enters the porous ceramic material chamber 4 from the pores, and continuously flows downward under the action of gravity to form an oil film on the surface of the porous ceramic material. Controlled by the circuit board, start the hot air blower 7 and start sending hot air 8 seconds after the spray nozzle starts to spray oil. The air supply volume is 1.3L. The hot air passes through the rectifying chamber 6 and the steady flow chamber 5 successively to form a steadily rising hot air flow. After entering the porous ceramic material chamber 4, the hot air v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com