A method for manufacturing a single-chip white light LED based on a lithium aluminate substrate and a structure thereof

A lithium aluminate substrate, single-chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost and complex lighting of multi-crystal LEDs, and achieve high quantum efficiency and hardness, high luminous efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

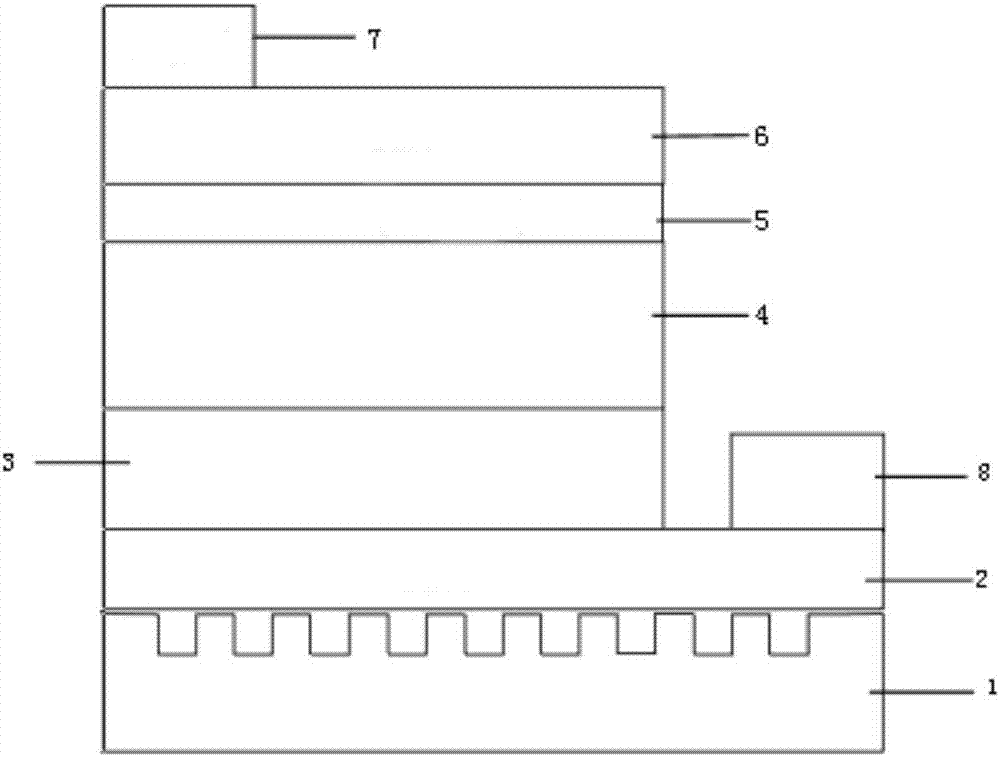

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. In conjunction with the following description, the advantages and characteristics of the present invention will be more clear. It should be noted that the accompanying drawings all use very simplified forms and inaccurate ratios. The purpose of this embodiment is explained for convenience and clarity.

[0026] In the present invention, a patterned lithium aluminate substrate is first prepared by a femtosecond laser etching process, and then a multi-quantum well InGaN / GaN LED is grown on the patterned substrate by MOCVD (metal organic chemical vapor deposition) method.

[0027] In this embodiment, the method for preparing a single-chip white light InGaN / GaN LED based on a lithium aluminate substrate includes the following steps:

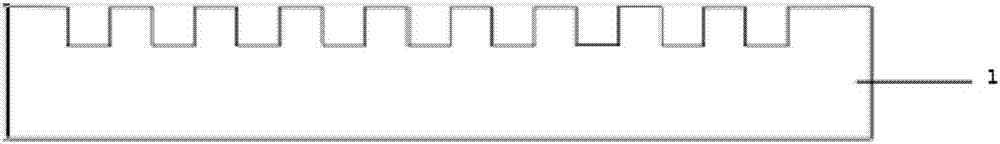

[0028] 1. Preparation of patterned lithium aluminate substrate, such as figure 1 Shown:

[0029] 1. The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com