Positive pole piece of capacitance type nickel-hydrogen power battery, preparation method of positive pole piece and battery prepared by positive pole piece

A positive pole piece, power battery technology, applied in the direction of battery electrodes, nickel storage batteries, alkaline storage battery electrodes, etc., can solve the problems of short battery life, achieve the effect of reducing oxygen generation and improving oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

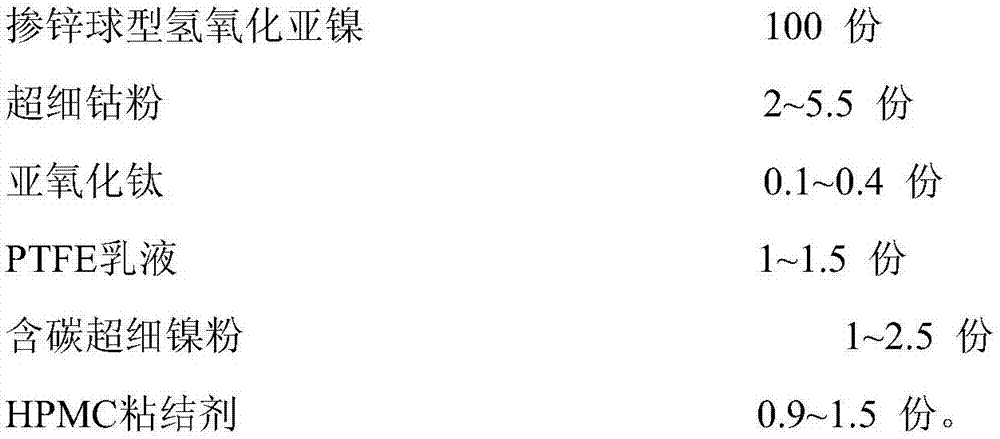

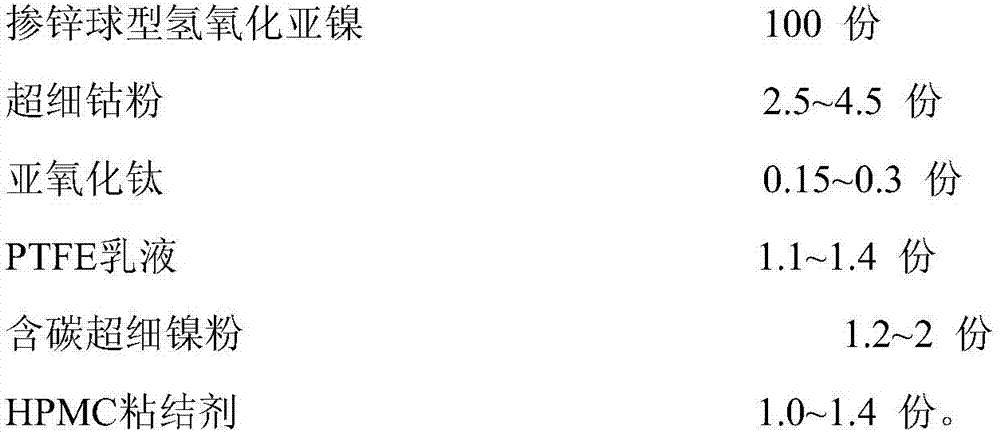

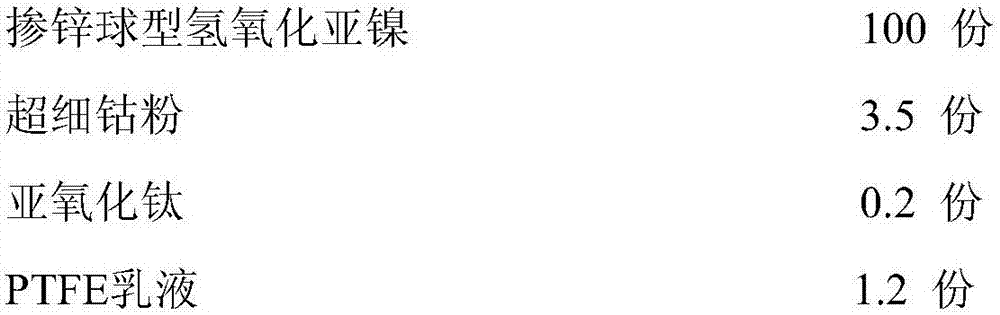

[0068] a. Preparation of positive and negative battery slurry:

[0069] Preparation of positive electrode battery slurry: according to zinc-doped spherical nickel hydroxide 100Kg, ultrafine cobalt powder 3.5Kg, titanium oxide 0.2Kg, HPMC binder 1.3Kg, PTFE emulsion 1.2Kg, carbon-containing ultrafine nickel powder 1.8 Kg, mixed evenly with deionized water accounting for 24% of the weight of the above-mentioned positive electrode battery material, to prepare positive electrode slurry.

[0070] Preparation of negative electrode battery slurry: according to the abundance of rare earth alloy 100Kg, activated carbon 0.9Kg, zinc oxide 10Kg, HPMC binder 3Kg, PTFE emulsion 2Kg, carbon-containing ultrafine nickel powder 3Kg, zinc powder 5Kg, and account for the above negative electrode battery materials 21% by weight of deionized water was evenly mixed to prepare negative electrode slurry.

[0071] b. Preparation of positive and negative electrodes: use 270g / m 2 Continuous wet coating...

Embodiment 2

[0076] a. Preparation of positive and negative battery slurry:

[0077] Preparation of positive battery slurry: 100Kg of zinc-doped spherical nickel hydroxide, 4.5Kg of superfine cobalt powder, 0.3Kg of titanium dioxide, 1.4Kg of HPMC binder, 1.4Kg of PTFE emulsion, 2Kg of carbon-containing superfine nickel powder , mixed evenly with deionized water accounting for 25% of the weight of the positive electrode battery material to prepare positive electrode slurry.

[0078] Preparation of negative electrode battery slurry: according to the abundance of rare earth alloy 100Kg, activated carbon 1.1Kg, zinc oxide 11Kg, HPMC binder 3.2Kg, PTFE emulsion 3.2Kg, carbon-containing ultrafine nickel powder 3.5Kg, zinc powder 5.5Kg, and accounted for 22% of the weight of the negative electrode battery material was mixed with deionized water evenly to prepare the negative electrode slurry.

[0079] b. Preparation of positive and negative electrodes: 300g / m 2 Continuous wet coating of foamed...

Embodiment 3

[0084] a. Preparation of positive and negative battery slurry:

[0085] Preparation of positive electrode battery slurry: according to zinc-doped spherical nickel hydroxide 100Kg, ultrafine cobalt powder 1.2Kg, titanium oxide 0.15Kg, HPMC binder 1.0Kg, PTFE emulsion 1.1Kg, carbon-containing ultrafine nickel powder 1.2 Kg, mixed evenly with deionized water accounting for 22% of the weight of the above-mentioned positive electrode battery material, to prepare positive electrode slurry.

[0086] Preparation of negative electrode battery slurry: according to the abundance of rare earth alloy 100Kg, activated carbon 0.6Kg, zinc oxide 8Kg, HPMC binder 2.8Kg, PTFE emulsion 2.4Kg, carbon-containing ultrafine nickel powder 2.5Kg, zinc powder 4Kg, and account for the above 20% of the weight of the negative electrode battery material was mixed with deionized water evenly to prepare the negative electrode slurry.

[0087] b. Preparation of positive and negative electrodes: 350g / m 2 Cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com