Liquid level detection device circuit board assembly and installation method thereof

A technology of liquid level detection and installation method, which is applied in the direction of buoy liquid level indicators, printed circuit components, laminated printed circuit boards, etc., and can solve problems such as large space occupation, high PCB board hardness, and damage to magnetic induction components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

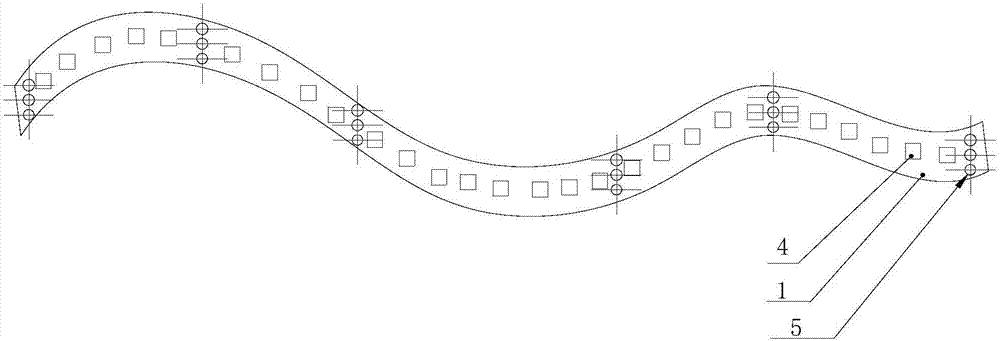

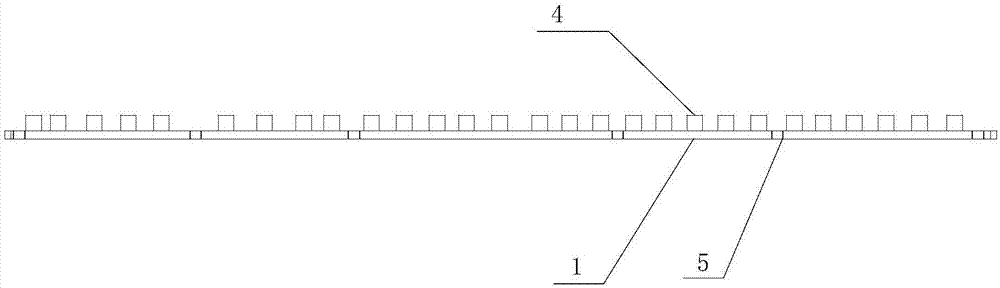

[0075] see Figure 1-Figure 4 As shown, this embodiment provides a circuit board assembly of a liquid level detection device, including a magnetic induction element 4, a first substrate 1, and a second substrate 2. The first substrate 1 is a flexible substrate, and on the first substrate 1 The magnetic induction element 4 is provided; the second substrate 2 is a non-magnetic substrate whose hardness is greater than that of the first substrate 1 , and the first substrate 1 is fixed on the second substrate 2 .

[0076] In the above solution, by arranging the magnetic induction element 4 on the flexible substrate, it is beneficial to roll and store, and facilitates later assembly. The present invention also provides a second substrate 2 with a hardness greater than that of the first substrate 1. The second substrate 2 The tensile strength of the sensor is improved, which is beneficial to the installation and debugging of circuit board components.

[0077]Preferably, the second s...

Embodiment 2

[0105] see figure 1 , figure 2 As shown, this implementation further describes the first substrate 1 on the basis of the first embodiment, the first substrate 1 is a flexible substrate, and the first substrate 1 is provided with a magnetic induction element 4 .

[0106] In the present invention, each magnetic induction element 4 is arranged on the first substrate 1, and the first substrate 1 has many advantages. The magnetic induction element 4 is arranged on the first substrate 1, which is beneficial to storage. For example, the first substrate 1 can be wound It is not necessary to use a hard printed circuit board as the substrate of the magnetic induction element 4 as in the prior art, so that the formed detection circuit is inconvenient to store and prone to wear and tear. On the other hand, in this embodiment, the first substrate 1 is used as the carrier of the magnetic induction element 4 , which is beneficial for cutting the first substrate 1 during the assembly proce...

Embodiment 3

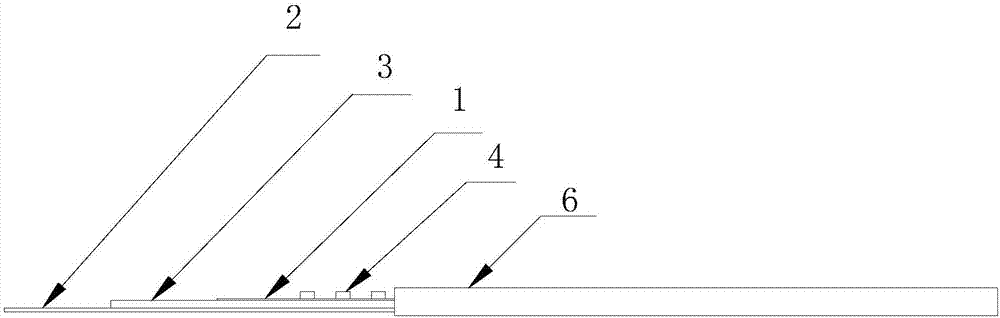

[0116] This embodiment provides a method for installing a circuit board assembly applied to the liquid level detection device in Embodiment 1, including the following steps:

[0117] S1. Cutting the first substrate 1 of the required length according to the process requirements;

[0118] S2. Cutting the second substrate 2 according to the length of the first substrate 1;

[0119] S3, bonding and fixing the first substrate 1 and the second substrate 2 through the third substrate 3;

[0120] S4. Put sealing sleeves 6 on each of the fixed substrates for encapsulation.

[0121] In the above step S1, the length of the first substrate 1 is cut according to the length required by the liquid level inspection device.

[0122] Preferably, in step S2, the second substrate 2 is cut to be longer than the first substrate 1, and a reserved section is formed at one end thereof for later connection and fixing with a corresponding installation structure to define the position of the circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com