Method for green preparation of 5-hydroxymethyl furfural from monosaccharide

A technology of hydroxymethyl furfural and monosaccharide, applied in the field of biomass, can solve the problems of high cost and difficult separation of products, and achieve the effects of simple process, easy industrialization and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

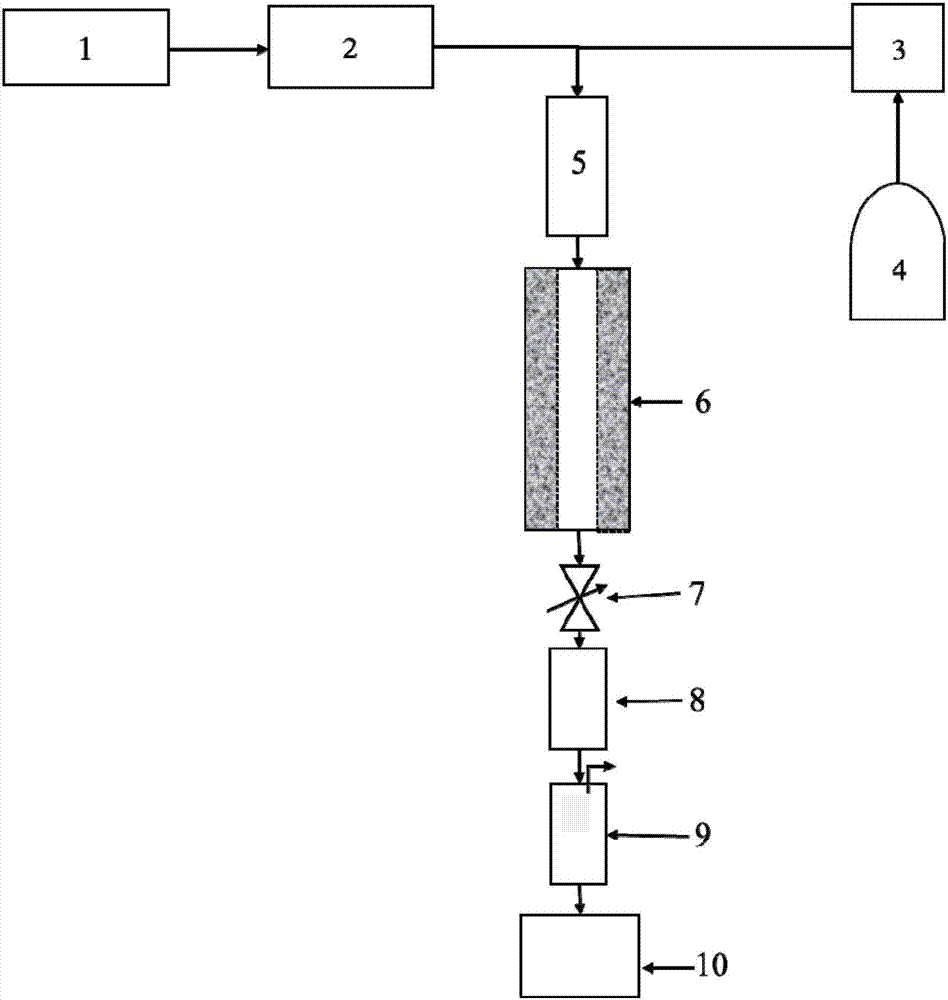

[0022] (1) Take 100ml of glucose solution with a concentration of 10% and put it into liquid storage tank 1;

[0023] (2) Take by weighing 40-60 order zirconium phosphate catalyst 1g and put into fixed bed reactor 6, tighten fixed bed reactor 6 joints;

[0024] (3) Nitrogen is fed into the fixed-bed reactor 6, the system pressure is increased to 3Mpa, and the nitrogen flow rate is set at 0.5L / min;

[0025] (4) The temperature of the fixed bed reactor 6 is set to be 160° C., and the temperature of the preheater 5 is 100° C., and the fixed bed reactor 6 and the preheater 5 are started to be heated;

[0026] (5) After the temperature of the preheater 5 and the fixed bed reactor 5 rises to the predetermined temperature respectively, the sugar solution is provided to the preheater 5 through the high-pressure advection pump 2, the water flow rate is 0.1ml / min, and the solution is in the preheater 5 Pass into fixed-bed reactor 6 after becoming gas-liquid state and mix with nitrogen;...

Embodiment 2

[0030] (1) Take 100ml of glucose solution with a concentration of 10% and put it into liquid storage tank 1;

[0031] (2) Take by weighing 40-60 order niobium phosphate catalyst 1g and put into fixed bed reactor 6, tighten fixed bed reactor 6 joints;

[0032] (3) Nitrogen is fed into the fixed-bed reactor 6, the system pressure is increased to 3Mpa, and the nitrogen flow rate is set at 0.5L / min;

[0033] (4) The temperature of the fixed bed reactor 6 is set to be 150° C., and the temperature of the preheater 5 is 100° C., and the fixed bed reactor 6 and the preheater 5 are started to be heated;

[0034] (5) After the temperature of the preheater 5 and the fixed bed reactor 5 rises to the predetermined temperature respectively, the sugar solution is provided to the preheater 5 through the high-pressure advection pump 2, the water flow rate is 0.1ml / min, and the solution is in the preheater 5 Pass into fixed-bed reactor 6 after becoming gas-liquid state and mix with nitrogen; T...

Embodiment 3

[0038] (1) Take 100ml of glucose solution with a concentration of 10% and put it into liquid storage tank 1;

[0039] (2) Weigh 1g of 40-60 mesh sulfated zirconia catalyst and put it into fixed-bed reactor 6, and tighten the fixed-bed reactor 6 joints;

[0040] (3) Nitrogen is fed into the fixed-bed reactor 6, the system pressure is increased to 3Mpa, and the nitrogen flow rate is set at 0.5L / min;

[0041] (4) The temperature of the fixed bed reactor 6 is set to be 180° C., and the temperature of the preheater 5 is 100° C., and the fixed bed reactor 6 and the preheater 5 are started to be heated;

[0042] (5) After the temperature of the preheater 5 and the fixed bed reactor 5 rises to the predetermined temperature respectively, the sugar solution is provided to the preheater 5 through the high-pressure advection pump 2, the water flow rate is 0.1ml / min, and the solution is in the preheater 5 Pass into fixed-bed reactor 6 after becoming gas-liquid state and mix with nitrogen;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com