Magnesium-tin-zinc-aluminum-manganese wrought magnesium alloy and preparing method thereof

A technology for deforming magnesium alloys and magnesium alloys, applied in the field of magnesium alloys, can solve the problems of composition design and preparation methods of magnesium alloys without deformation, and achieve the effects of homogenization and low solution heat treatment temperature, improving strength and toughness, and excellent plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a low-cost magnesium-tin-zinc-aluminum-manganese deformed magnesium alloy and a preparation method thereof.

[0025] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0026] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0027] The percentages used in the following examples are all mass percentages unless otherwise specified.

Embodiment 1

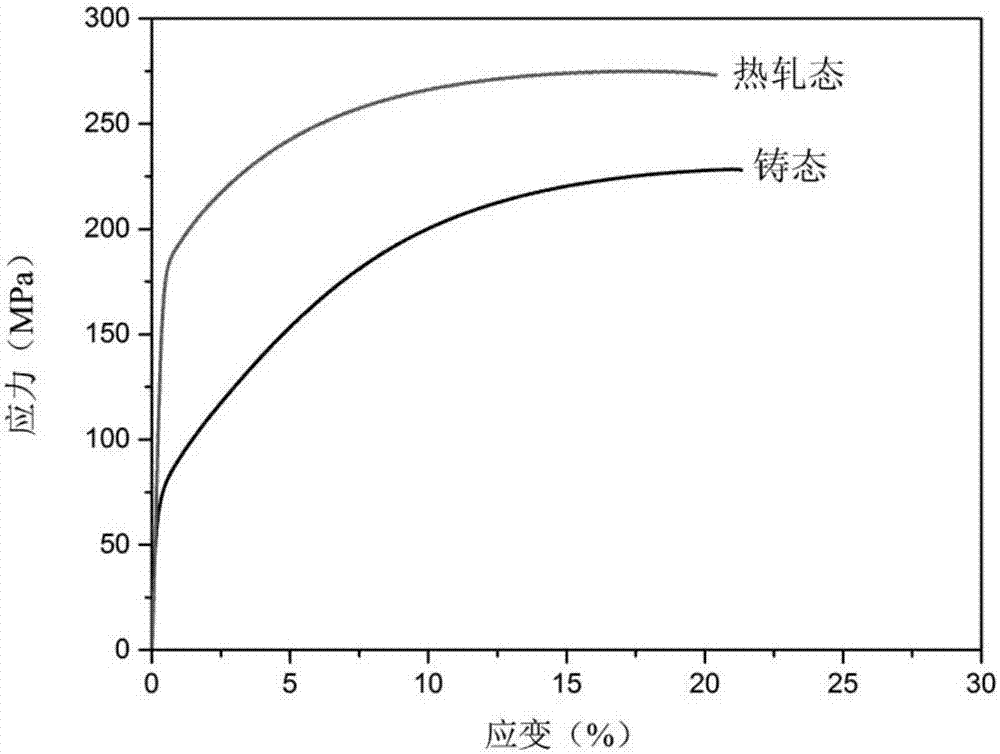

[0029] The hot-rolled sheets of Mg-2Sn-2Zn-2Al-0.2Mn alloy were prepared and the mechanical properties of the materials were measured.

[0030] The process flow is: raw material preparation and batching→alloy smelting and casting→homogenizing annealing→hot rolling→finished plate.

[0031] With pure Mg (99.9%), pure Sn (99.99%), pure Zn (99.99%), pure Al (99.99%) and pure Mn (99.9%) as raw materials, according to Sn, Zn and Al are 2%, Mn is 0.2%, the balance is Mg ingredients, Al put into the vacuum induction melting furnace 2 o 3 in the crucible. Vacuumize first, and after the pressure in the vacuum induction melting furnace drops to 20Pa, argon gas is introduced to make the pressure of argon gas reach 0.04MPa. The Al containing raw material was then heated under the protection of argon 2 o 3 The crucible was refined at 800°C for 3 minutes, and then the alloy melt was poured into a cylindrical high-purity graphite mold with a diameter of 75mm, and cooled to room temperatu...

Embodiment 2

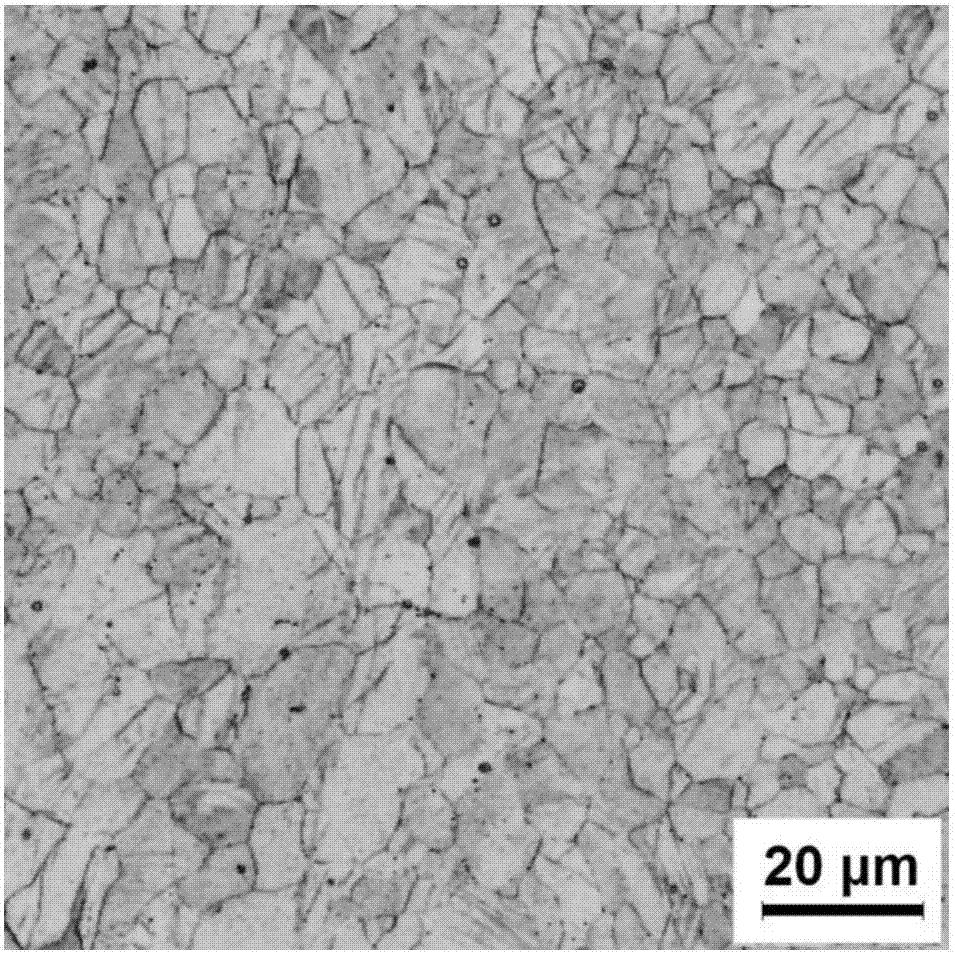

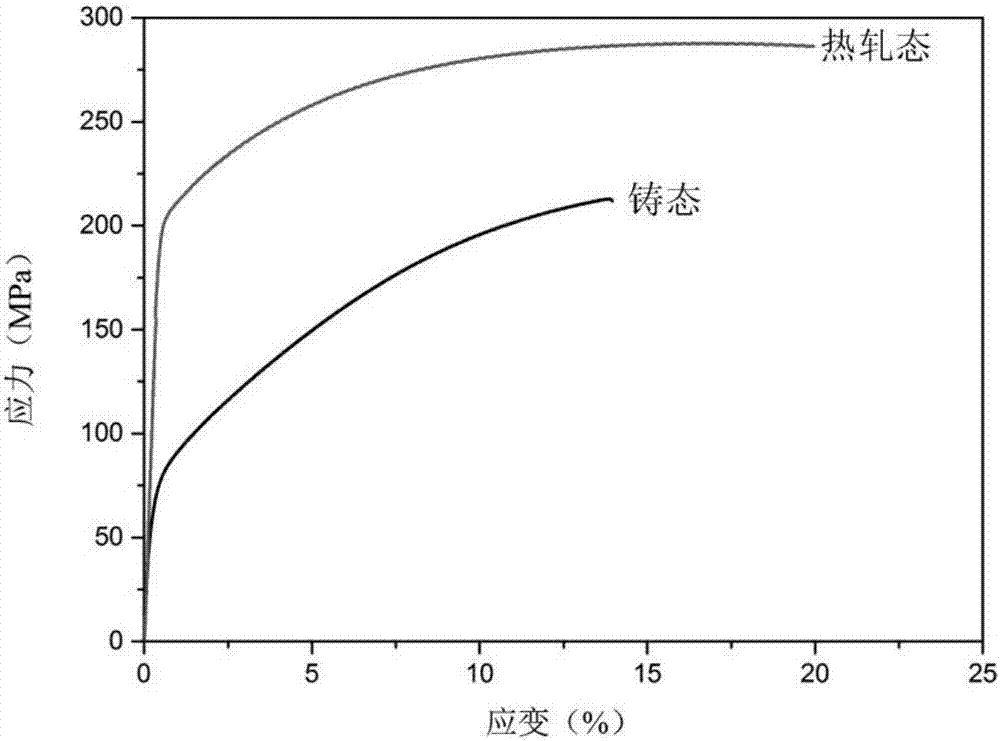

[0036] The hot-rolled sheets of Mg-4Sn-2Zn-2Al-0.2Mn alloy were prepared and the mechanical properties of the materials were measured.

[0037] The process flow is: raw material preparation and batching→alloy smelting and casting→homogenizing heat treatment→hot rolling→finished plate.

[0038] Using pure Mg (99.9%), pure Sn (99.99%), pure Zn (99.99%), pure Al (99.99%) and pure Mn (99.9%) as raw materials, Sn is 4%, Zn and Al are 2% , Mn is 0.2%, the balance is Mg ingredients, Al put into the vacuum induction melting furnace 2o 3 in the crucible. Vacuumize first, and after the pressure in the vacuum induction melting furnace drops to 20Pa, argon gas is introduced to make the pressure of argon gas reach 0.04MPa. The Al containing raw material was then heated under the protection of argon 2 o 3 The crucible was refined at 800°C for 3 minutes, and then the alloy melt was poured into a cylindrical high-purity graphite mold with a diameter of 75mm, and cooled to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com