Flavored ready-to-eat natto

A natto and flavor technology, applied in the field of food processing, can solve problems such as less consumption, and achieve the effects of increasing strong taste, rich raw materials, and delaying aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

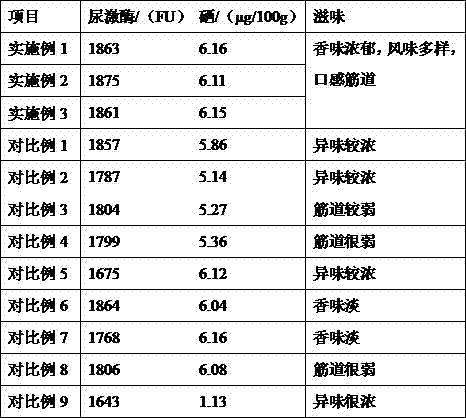

Examples

Embodiment 1

[0023] A flavored instant natto, made of the following raw materials in parts by weight: 87 soybeans, 2 bacteria natto, 1.5 spices, 2 pomelo peels, 8 eggs, 21 millet, and 6 konjac starch;

[0024] The spices are made of the following raw materials in parts by weight: salt 23, pepper 7, pepper 7, pepper 6, star anise 5, grass fruit 4, nutmeg 4, amomum 4, all raw materials are mixed and crushed to 160~ 200 mesh, stir-fry until fragrant, add 400 times the weight of all raw materials in water, heat to boil, cook on low heat until the volume is 1 / 50 of the original volume, and dry until the water content is 8-10% to obtain spices.

[0025] For the grapefruit peel, peel the ripe grapefruit, remove the inner flesh, and dry the skin until the water content is 8-10%, so as to obtain the grapefruit peel.

[0026] The eggs are fresh green shell eggs with a selenium content of 48-52 μg / 100g.

[0027] A preparation method of flavor instant natto, comprising the following steps:

[0028] ...

Embodiment 2

[0039] A flavor instant natto, made of the following raw materials in parts by weight: 88 soybeans, 3 natto bacteria, 1.6 spices, 3 pomelo peels, 9 eggs, 22 millet, and 7 konjac starch;

[0040] The spices are made of the following raw materials in parts by weight: 24 salt, 8 peppers, 8 peppers, 7 peppercorns, 6 star anise, 5 grass fruit, 5 nutmeg, and 5 amomum. Mix all the raw materials and grind them to 180 mesh , stir-fry until fragrant, add water 450 times the weight of all raw materials, heat to boil, cook on low heat until the volume is 1 / 50 of the original volume, and dry until the water content is 8-10% to obtain spices.

[0041] For the grapefruit peel, peel the ripe grapefruit, remove the inner flesh, and dry the skin until the water content is 8-10%, so as to obtain the grapefruit peel.

[0042] The eggs are fresh green shell eggs with a selenium content of 48-52 μg / 100g.

[0043] Preparation and eating method are the same as in Example 1.

Embodiment 3

[0045] A flavored instant natto, made of the following raw materials in parts by weight: 89 soybeans, 4 natto bacteria, 1.7 spices, 4 pomelo peels, 10 eggs, 23 millet, and 8 konjac starch;

[0046] The spices are made of the following raw materials in parts by weight: salt 25, pepper 9, pepper 9, Chinese prickly ash 8, star anise 7, grass fruit 6, nutmeg 6, amomum 6, all raw materials are mixed and crushed to 160~ 200 mesh, stir-fry until fragrant, add 500 times the weight of all raw materials in water, heat to boil, cook on low heat until the volume is 1 / 50 of the original volume, and dry until the water content is 8-10% to obtain spices.

[0047]For the grapefruit peel, peel the ripe grapefruit, remove the inner flesh, and dry the skin until the water content is 8-10%, so as to obtain the grapefruit peel.

[0048] The eggs are fresh green shell eggs with a selenium content of 48-52 μg / 100g.

[0049] Preparation and eating method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com