Preparation method of high-strength bamboo plywood

A technology of high-strength bamboo and plywood, which is used in the joining of wooden veneers, manufacturing tools, and reed/straw treatment. It can solve the problems of poor mechanical strength and toughness of bamboo plywood, and improve mechanical strength and toughness. , the effect of improving toughness and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

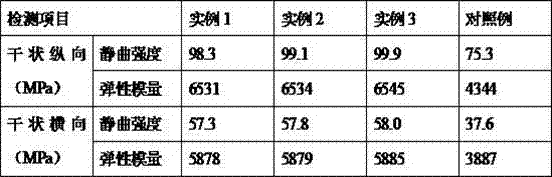

example 1

[0023] Take pine sawdust and 20% sodium hydroxide solution with a mass fraction of 1:10, mix them with a mass ratio of 1:10, heat and boil for 1 hour, filter and separate to obtain the filtrate, adjust the pH of the filtrate to 5.5 with a concentration of 1mol / L hydrochloric acid, and then use a centrifuge to Centrifuge at a speed of 3000r / min for 10min, separate and obtain the lower precipitate; add phenol into a four-neck flask equipped with a condenser, a thermometer and a stirrer, heat up to 50°C, start the stirrer to stir and mix at a speed of 100r / min, and Add the above precipitate with 40% phenol mass and alumina powder with 1% phenol mass to the four-necked flask under stirring, heat up to 80°C, keep warm for liquefaction reaction for 20min, and obtain the liquefied product, cool the liquefied product to 45°C, and then Add 5% of the liquefied product mass fraction to 10% formaldehyde solution into the four-neck flask, heat up to 55°C, continue stirring and reacting for ...

example 2

[0025]Take pine sawdust and 20% sodium hydroxide solution with a mass fraction of 1:10, mix them, heat and boil for 2 hours, filter and separate to obtain the filtrate, adjust the pH of the filtrate to 5.8 with a concentration of 1mol / L hydrochloric acid, and then use a centrifuge to Centrifuge at 3500r / min for 13min to separate and obtain the lower precipitate; add phenol to a four-neck flask equipped with a condenser, thermometer and stirrer, heat to 55°C, start the stirrer to stir and mix at 150r / min, Add the above-mentioned precipitate with 40% phenol mass and alumina powder with 1% phenol mass to the four-neck flask under stirring, heat up to 85°C, keep warm for liquefaction reaction for 25min, and obtain the liquefied product, cool the liquefied product to 48°C, and then Add 5% of the liquefied product mass fraction to 10% formaldehyde solution into the four-neck flask, heat up to 60°C, continue stirring and reacting for 55 minutes, and obtain self-made bamboo board glue;...

example 3

[0027] Take pine sawdust and 20% sodium hydroxide solution with a mass fraction of 1:10, mix them with a mass ratio of 1:10, heat and boil for 2 hours, filter and separate to obtain the filtrate, adjust the pH of the filtrate to 6.0 with a concentration of 1mol / L hydrochloric acid, and then use a centrifuge to Centrifuge at a speed of 4000r / min for 15min to separate and obtain the lower precipitate; add phenol to a four-neck flask equipped with a condenser, thermometer and stirrer, heat up to 60°C, start the stirrer to stir and mix at a speed of 200r / min, and Add the above precipitate with 40% phenol mass and alumina powder with 1% phenol mass to the four-necked flask under stirring, heat up to 90°C, keep warm for liquefaction for 30min, and obtain the liquefied product, cool the liquefied product to 50°C, and then Add 5% of the liquefied product mass fraction to 10% formaldehyde solution into the four-neck flask, heat up to 65°C, continue stirring and reacting for 60 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com