Salted duck egg production equipment and process

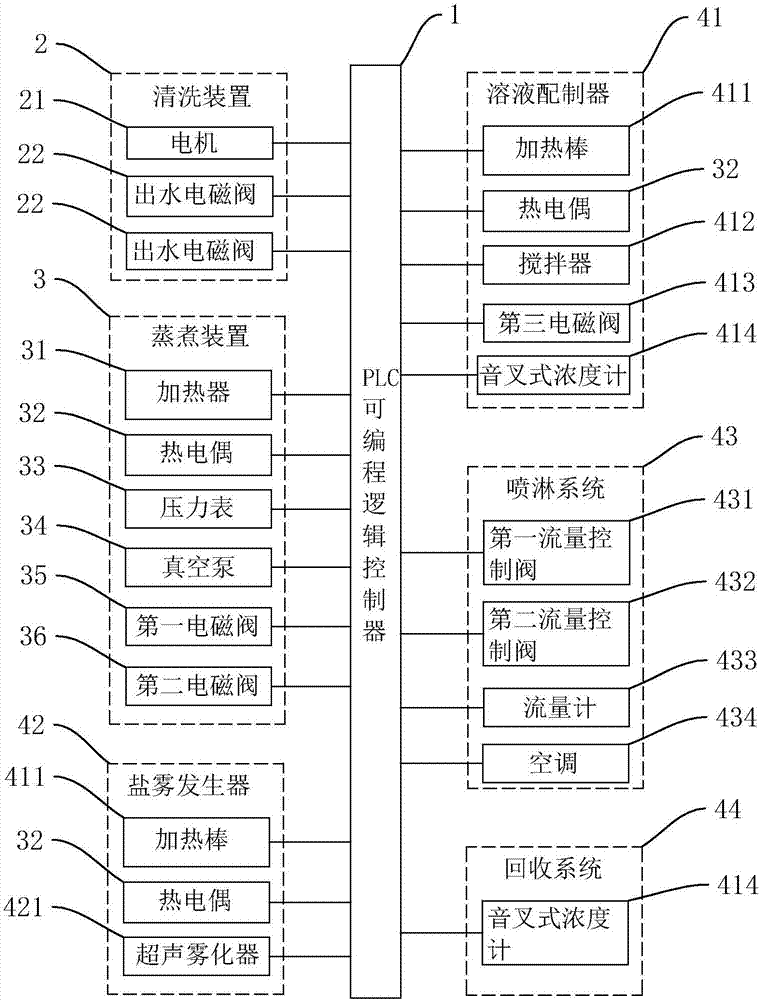

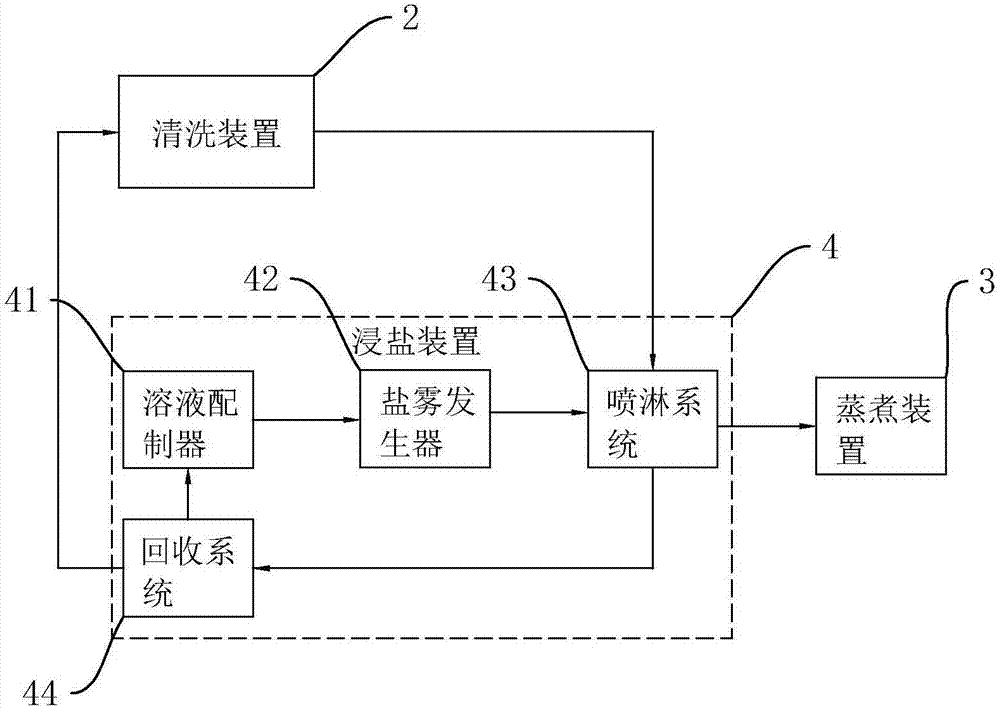

A salted duck egg and duck egg technology, which is applied in the field of salted duck egg production equipment and production technology, can solve the problems of uncontrollable salt content balance and uneven saltiness of duck eggs, and achieve the effects of convenient transportation, accelerated atomization speed, and prevention of dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The production process of salted duck eggs:

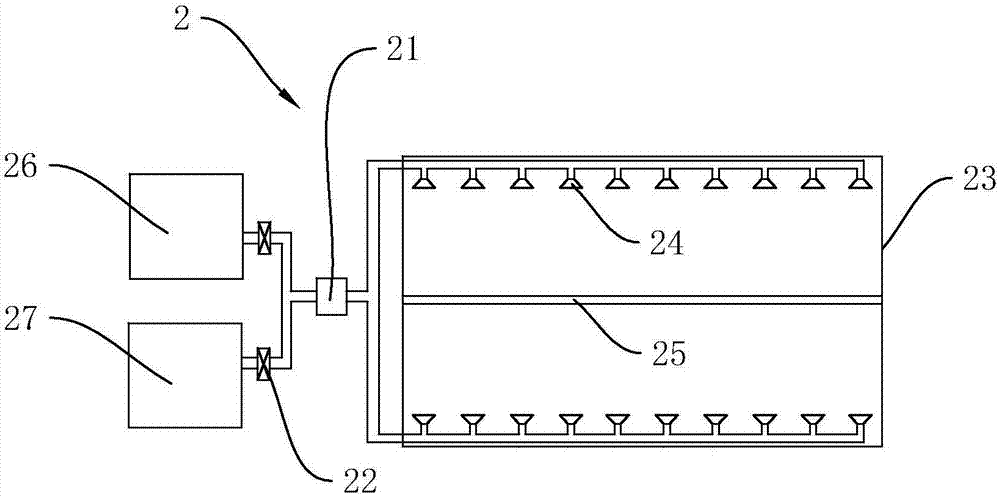

[0068] Such as Figure 10 Shown, (1) cleaning: duck eggs are placed on the lower fixing frame, the upper fixing frame is fixed on the lower fixing frame, the duck egg fixing frame is fixed on the upper fixing plate and the lower fixing plate of the cleaning rack, and the cleaning device is used to Use 1.2% (wt) sodium dodecylsulfonate aqueous solution to clean the stains on the duck eggs, the sodium dodecylsulfonate aqueous solution also includes zeolite, and the weight of zeolite is 5% of the sodium dodecylsulfonate aqueous solution weight , then with the sodium chloride aqueous solution of 4% (wt) concentration, the residual sodium lauryl sulfonate on the duck's egg is cleaned up, and after cleaning is finished, the duck's egg is dried on the duck's egg fixed rack;

[0069] (2) Soak salt preparation: place the duck egg fixing rack and duck eggs obtained in step (1) on the upper fixing plate and the lower fixing plate of t...

Embodiment 2

[0076] The production process of salted duck eggs:

[0077] (1) Cleaning: the duck eggs are placed on the lower fixing frame, the upper fixing frame is fixed on the lower fixing frame, the duck egg fixing frame is fixed on the upper fixing plate and the lower fixing plate of the cleaning rack, and the cleaning device is used to use 0.8% (wt) the sodium dodecylsulfonate aqueous solution of concentration cleans the spot on the duck egg, the sodium dodecylsulfonate aqueous solution also comprises zeolite, and the weight of zeolite is 5% of the sodium dodecylsulfonate aqueous solution weight, then use The sodium chloride aqueous solution of 4% (wt) concentration cleans up the residual sodium lauryl sulfonate on the duck's egg, and after cleaning is completed, the duck's egg is dried on the duck's egg fixed rack;

[0078] (2) Soak salt preparation: place the duck egg fixing rack and duck eggs obtained in step (1) on the upper fixing plate and the lower fixing plate of the spray cab...

Embodiment 3

[0085] The production process of salted duck eggs:

[0086] (1) Cleaning: the duck eggs are placed on the lower fixing frame, the upper fixing frame is fixed on the lower fixing frame, the duck egg fixing frame is fixed on the upper fixing plate and the lower fixing plate of the cleaning rack, and the cleaning device is used to use 1.1% (wt) the sodium dodecylsulfonate aqueous solution of concentration cleans the spot on the duck egg, the sodium dodecylsulfonate aqueous solution also comprises zeolite, and the weight of zeolite is 5% of the sodium dodecylsulfonate aqueous solution weight, then use The sodium chloride aqueous solution of 4% (wt) concentration cleans up the residual sodium lauryl sulfonate on the duck's egg, and after cleaning is completed, the duck's egg is dried on the duck's egg fixed rack;

[0087] (2) Soak salt preparation: place the duck egg fixing rack and duck eggs obtained in step (1) on the upper fixing plate and the lower fixing plate of the spray cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com