Laser welding plume control and molten bath protection method and device

A laser welding and protection device technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of reduced flexibility of laser welding, reduced performance of welded joints, increased thermal deformation of workpieces, etc., to improve energy utilization and welding efficiency, improved stability and weld shape, improved weld protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

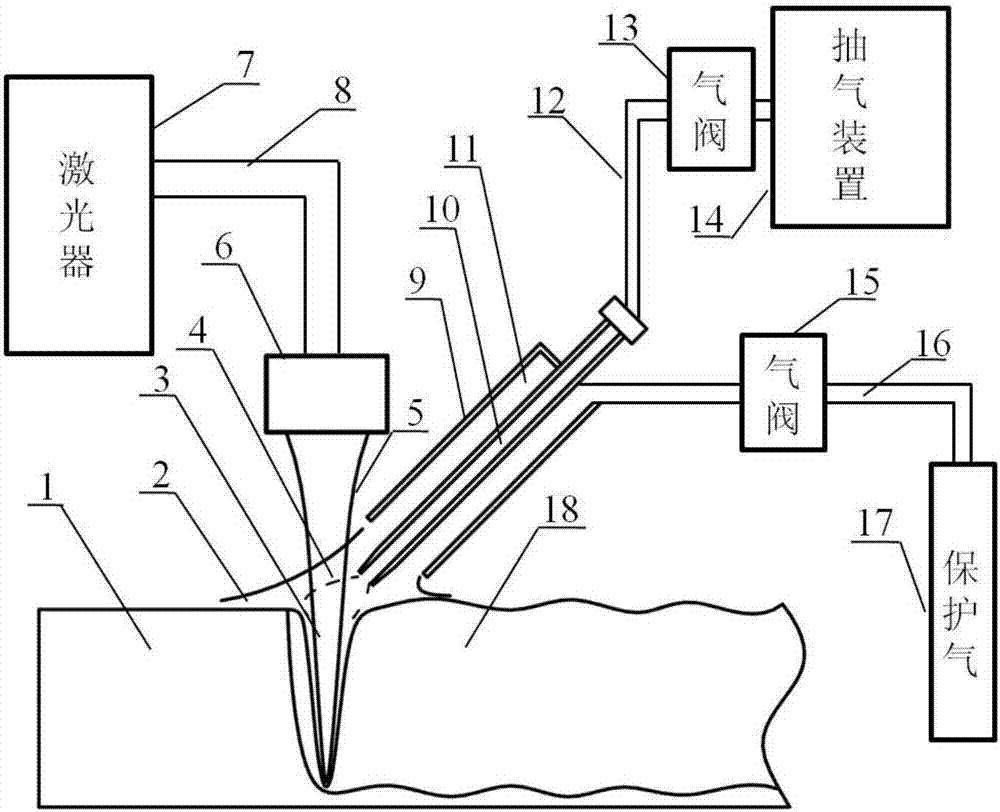

[0019] figure 1 Schematic diagram of a laser welding device for controlling the plume and protecting the molten pool for a coaxial double-layer nozzle, wherein the welding device includes a laser beam 5, a coaxial double-layer nozzle 9 (including an inner tube 10 and an outer tube 11), and an air pump that provides negative pressure The device 14 and the gas cylinder 17 providing shielding gas, wherein the workpiece 1 is the welding object, the deep penetration hole 3, the plume 4, the welding pool and the weld seam 18 are formed during the welding process; during welding, the laser beam 5 acts For the workpiece 1, the positions of the double-layer nozzle 9 and the laser beam 5 are relatively fixed; the negative air pressure and the protective air flow 2 are respectively generated in the inner tube 10 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com