Flowmeter acieral rotating impeller rapid moulding and surface hardening anti-corrosion process

A technology of rotating impellers and aluminum-based alloys, which is applied in the field of rapid prototyping of aluminum-based alloy rotating impellers for flowmeters and surface hardening and corrosion-resistant technology. It can solve problems such as difficult processing, affecting service life, and affecting product service life. Strong grinding performance and corrosion resistance, saving production costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention provides a rapid prototyping and surface hardening anti-corrosion process of an aluminum-based alloy rotary impeller for a flowmeter, comprising the following steps:

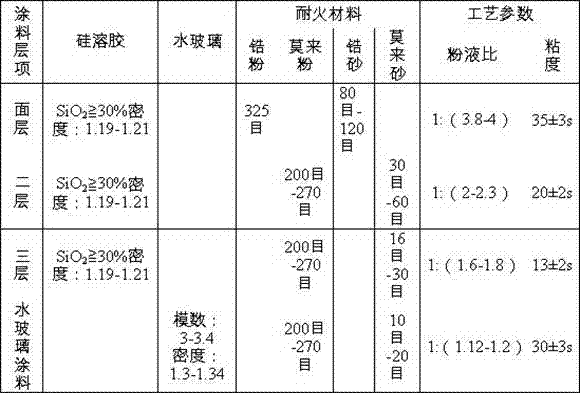

[0040] 1) Aluminum-based alloy rotary impeller formed by composite casting of silica sol:

[0041] ①Aluminum mold production: Eight-petal split mold is used. The inner cavity of the mold is carved out of the outer surface of the rotating impeller by turning. The hollow reserved position is the molding cavity of the wax pattern of the rotating impeller. There is a small pressure relief and diversion hole at the tail end of the eight impellers of the impeller, and a gripping position is provided in the middle of the outer end of the eight-petal module, and the eight-petal module of the mold is embracing and pre-tightened with the matching quick clamp. Aluminum mold making is the most critical step in the forming of the rotary impeller. Whether the pressed wax parts can be released from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com