Salt pan tedding technology of high-magnesium and low-potassium sulfate brine

A sulfate-type, high-magnesium-low-potassium technology, which is applied in the field of salt chemical industry, can solve the problems that brine resources cannot produce added value, high products, and low output of potassium-magnesium mixed salt, so as to improve resource recovery rate and product added value , Process controllable, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

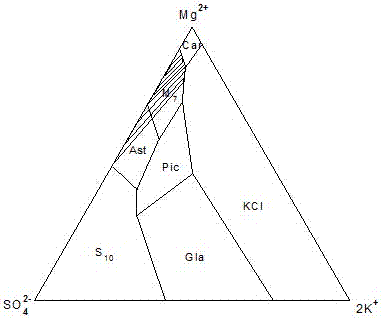

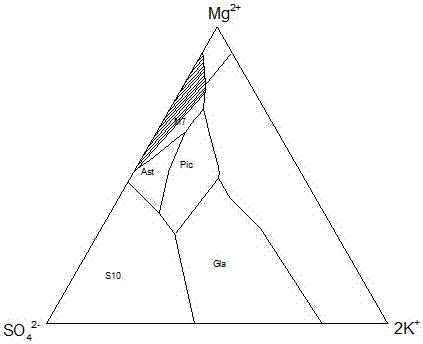

Image

Examples

Embodiment 1

[0037] Example 1: The raw brine used in this example (that is, high magnesium and low potassium sulfate type brine) is the same as that in Comparative Example 1; it is tanned at 15°C.

[0038] (1) Import high-magnesium and low-potassium sulphate-type brine into the sodium chloride salt field, and naturally spread out the sodium chloride. When the brine point reaches the saturation of Epsom salt and begins to precipitate Epsom salt, introduce the brine into the Epsom salt field; The mineral precipitated in the sodium chloride salt field is sodium chloride; (2) Evaporate the brine introduced into the Epsom salt salt field, and when the precipitation of the Epsom salt is 45wt%, the brine is introduced into the first-grade carnallite salt field, and the Epsom salt The minerals precipitated in the salt field are mixed salts composed of sodium chloride and epsom salt;

[0039] (3) Evaporate the brine imported into the first-grade carnallite salt field until the amount of carnallite ...

Embodiment 2

[0046] The original brine used in this example (that is, high magnesium and low potassium sulfate type brine) is the same as that in Comparative Example 2; it was tanned at 25°C.

[0047] (1) Import high-magnesium and low-potassium sulphate-type brine into the sodium chloride salt field, and naturally spread out the sodium chloride at 25°C. Liyan salt field; the mineral precipitated in the sodium chloride salt field is sodium chloride;

[0048] (2) Evaporate the brine introduced into the epsom salt field until the precipitation of epsom salt is 65wt%, then introduce the brine into the first-grade carnallite salt field, and the minerals precipitated in the epsom salt field are composed of sodium chloride and salt mixtures;

[0049] (3) When the brine introduced into the first-grade carnallite salt field is evaporated until the amount of carnallite precipitation is 40wt%, the brine is introduced into the second-grade carnallite salt field; when the brine reaches potassium satur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com