Evaporator for wastewater evaporation

An evaporator and waste water technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of poor waste water treatment effect, failure to meet waste water treatment standards, etc., and achieve low resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

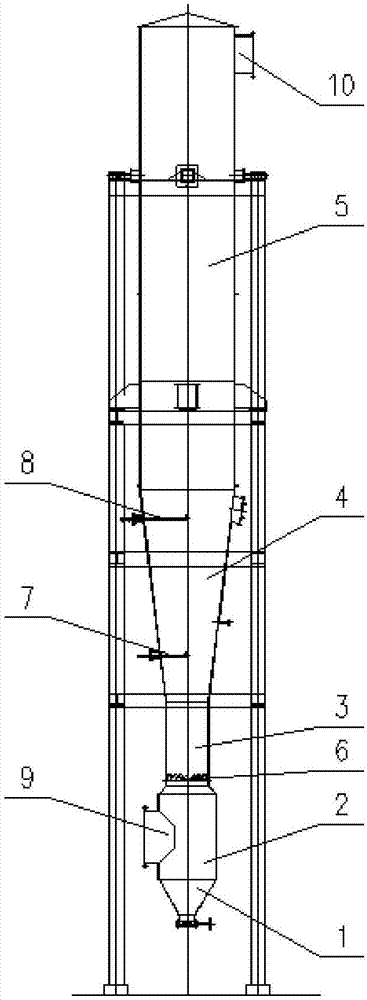

[0025] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment. An evaporator for wastewater evaporation in this embodiment includes an evaporator ash hopper 1, an evaporator inlet section 2, a constriction transition section 3, a cone barrel expansion section 4, an evaporation section 5, and a swirl rectifier 6. The first-stage dual-fluid spray gun 7 and the second-stage dual-fluid spray gun 8, the side of the evaporator inlet section 2 is provided with an air inlet flue 9, and the lower end of the evaporator inlet section 2 is connected to the evaporator ash hopper 1, The upper end of the inlet section 2 of the evaporator is connected to the necking transition section 3, the upper end of the necking transition section 3 is connected to the cone barrel expansion section 4, and the upper end of the cone barrel expansion section 4 is connected to the evaporation section 5, and the evaporation section 5 The top side of the top is provided with an ou...

specific Embodiment approach 2

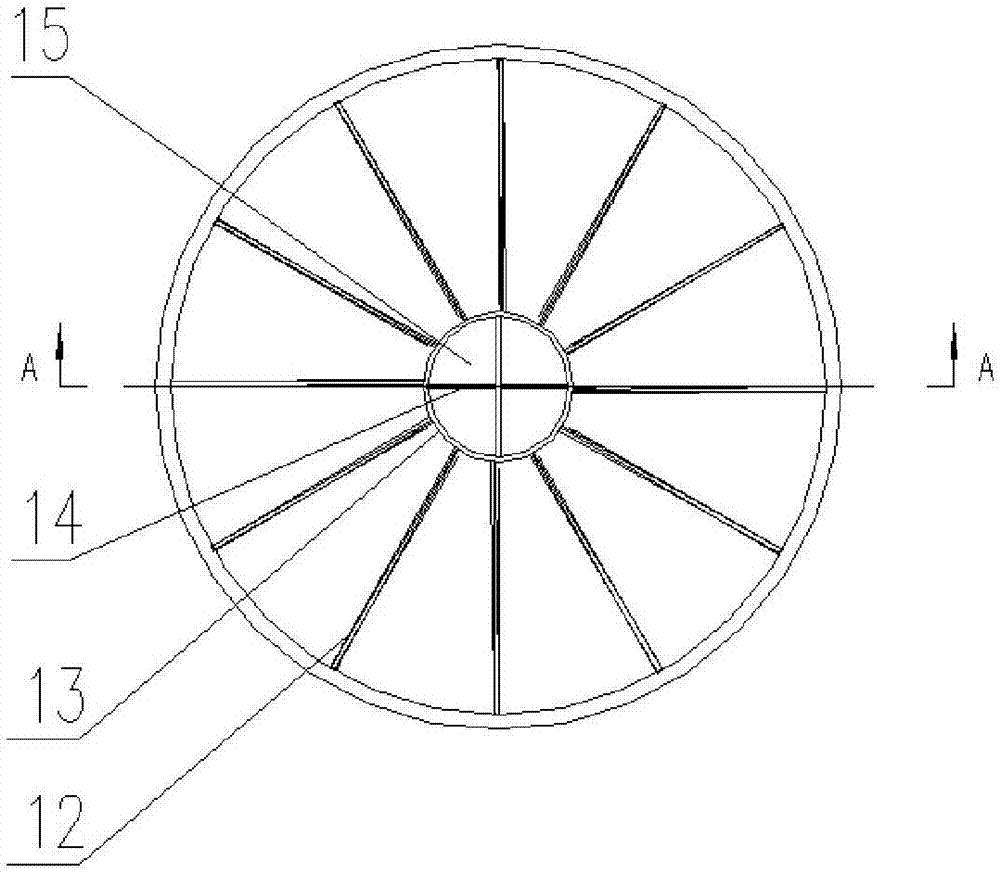

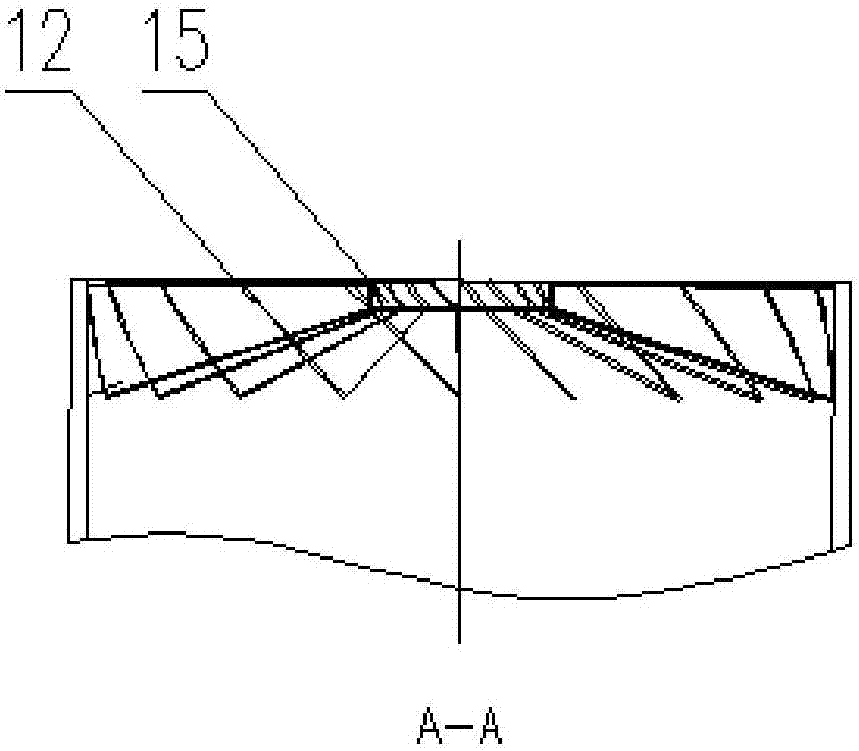

[0027] Specific implementation mode two: combination Figure 1-Figure 3 To illustrate this embodiment, the swirl rectifier 6 described in an evaporator for evaporating waste water in this embodiment is arranged at the entrance of the constricted transition section 3, and the swirl rectifier 6 is arranged to cover the entrance of the constricted transition section 3. Section; the swirl rectifier 6 includes rectifying blades 12, a rectifier central cylinder 13, a cross rib 14 and a central cylinder cover plate 15, and the rectifier central cylinder 13 is arranged at the entrance center of the necking transition section 3, and the rectifier The central cylinder 13 is supported and fixed by cross ribs 14 , the rectifying vanes 12 are evenly distributed along the circumference of the rectifier central cylinder 13 , and the upper and lower ends of the rectifier central cylinder 13 are closed by the central cylinder cover plate 15 . In this way, the flue gas enters the initial stage ...

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the constricted transition section 3 of the evaporator for evaporating wastewater in this embodiment is a cylindrical structure, and the diameter of the constricted transition section 3 is smaller than the diameter of the inlet section 2 of the evaporator. In this way, the flow rate of the flue gas in the constricted transition section 3 is accelerated compared with that in the evaporator inlet section 2, and the diameter of the constricted transition section 3 is smaller than that of the evaporator inlet section 2, which is convenient for compressing the flue gas, and is convenient for the expansion section of the cone barrel. 4 connections.

[0029] Specific implementation mode four: combination figure 2 Describe this embodiment, the rectifying blades 12 described in an evaporator for wastewater evaporation in this embodiment are evenly distributed along the circumference around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com