Environment-friendly device for rapidly evaporating water and liquid and structure thereof

A rapid evaporation and liquid technology, applied in the direction of water/sewage treatment, heating water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of large energy consumption, slow evaporation speed, waste of resources, etc., to improve evaporation rate, The effect of fast evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

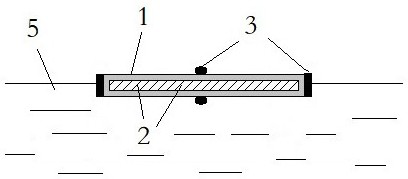

[0058] This embodiment provides a medium-sized floating evaporator, such as figure 1 , 2As shown, it includes an evaporation layer 1, a floating body 2, and a water absorbent 3; the evaporation layer 1 is a natural fiber and / or chemical fiber and its fabric (such as absorbent cotton yarn, quick-drying imitation cotton cloth, etc.) with a thickness of 0.1mm-1mm, as long as it can be wetted by the water and solution 5 and have a capillary structure on the surface and / or inside), the overall size is designed according to the floating body 2; the floating body 2 is 10mm-20mm in thickness and 50mm-100mm in diameter , circular flakes that can float on water and liquid 5 (such as polystyrene foam boards, hollow objects made of waterproof rubber, etc., as long as they can float on the water and liquid 5); The water-absorbent 3 is a cylinder-shaped water-absorbent object (such as absorbent cotton sliver, absorbent sponge, etc.) with any length and a diameter of 5mm-10mm, as long as i...

no. 2 example

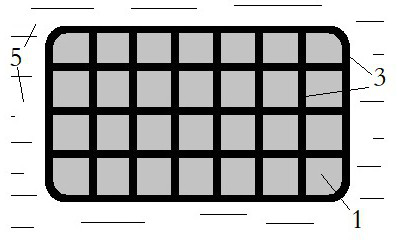

[0061] This embodiment provides a large floating evaporator, such as Figure 3-6 As shown, it includes an evaporation layer 1, a floating body 2, and a water absorbent 3; the specific composition, structure, and working principle of this embodiment are basically the same as those of the first embodiment, and the differences with the first embodiment are: one is that the floating body 2 is any size and any shape, such as a rectangular sheet with a length of 100mm-1000mm, a width of 50mm-500mm, and a thickness of 10mm-20mm. The evaporation layer 1 is adjusted according to the size and shape of the floating body 2; The second is that the large-scale floating evaporator is evenly distributed with holes, gaps, pipes, etc. that penetrate the middle part of the floating body 2 and are filled by the absorbent 3, that is, use the absorbent 3 to pass through the floating body 2 The middle is in direct contact with the water and liquid 5 below it, so as to use the capillary phenomenon of...

no. 3 example

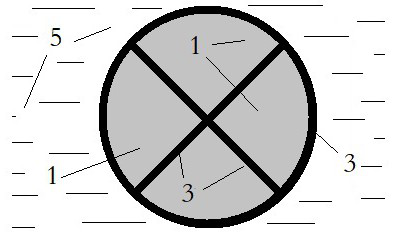

[0063] This embodiment provides a small floating evaporator, such as Figure 7 , 8 As shown, it includes an evaporation layer 1 and a floating body 2; the specific composition, structure, and working principle of this embodiment are basically the same as those of the first embodiment, and the differences with the first embodiment are: one is the small floating evaporator The water absorbent 3 is not provided, and the capillary phenomenon of the evaporation layer 1 is used to replenish water; the second is that the size of the small floating evaporator is small (such as a spherical object with a diameter of 10mm-30mm), so as to better Make use of the hair phenomenon to replenish water, realize that as long as the small floating evaporator is placed on the surface of the water and the solution 5, all parts of the evaporation layer 1 can be moistened by the water and the solution 5 Wet effect; if this effect cannot be achieved, further reduce the diameter of the floating body 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com