A kind of high-performance film printing emulsion, preparation method and application thereof

A film printing, high-performance technology, used in applications, household appliances, inks, etc., can solve the problem of no connecting material, and achieve the effect of fast drying, stable operability, and high ethanol tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

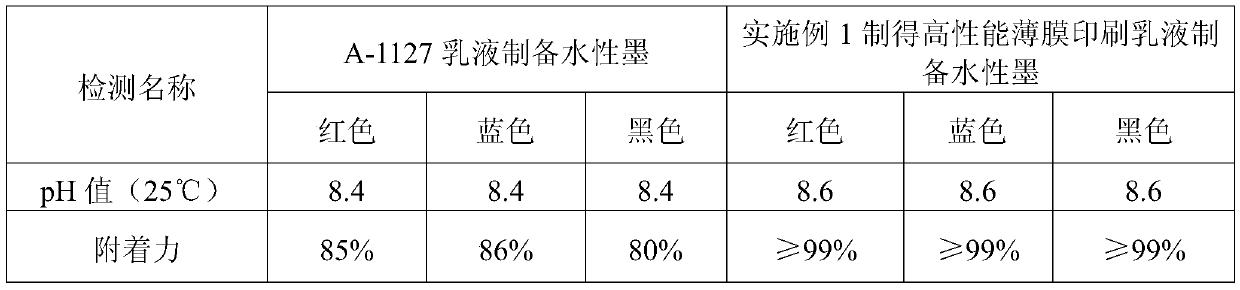

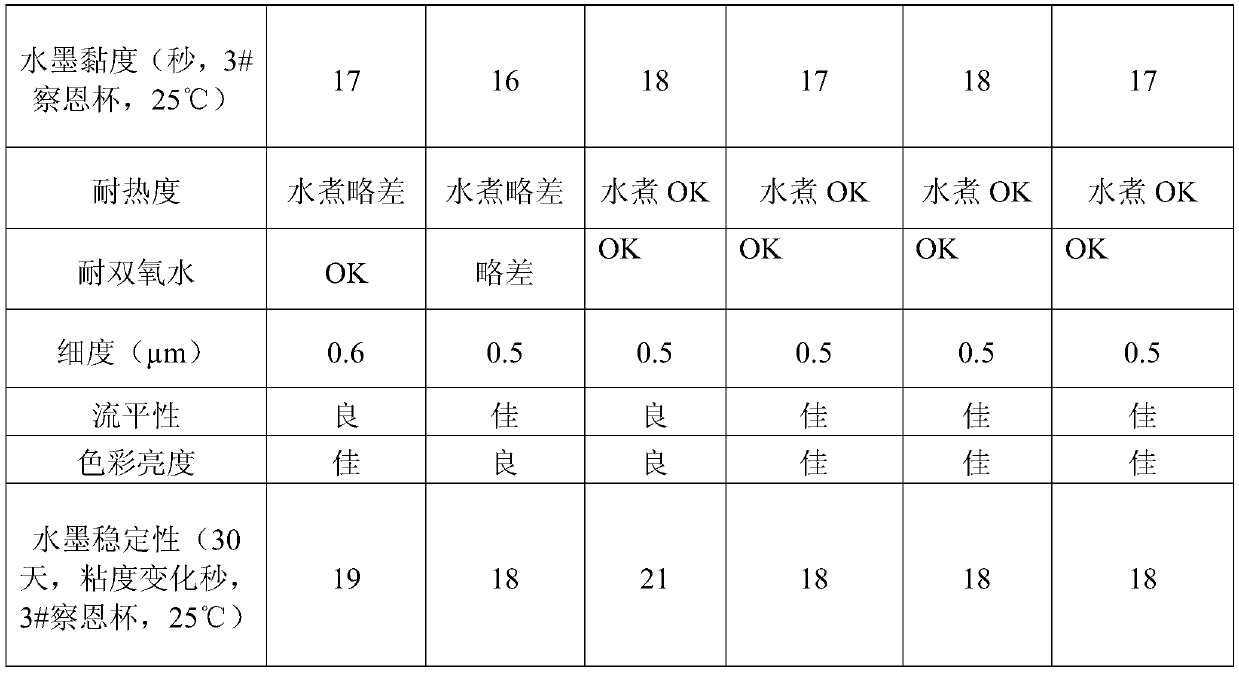

Examples

Embodiment 1

[0035] Seed core-shell emulsion polymerization: 611.9 grams of deionized water and 4 grams of ammonium persulfate were added to a four-necked flask with a thermometer, a reflux condenser, a dripping device, and agitation to mix and dissolve to obtain solution A; solution A was heated to 85°C, feed nitrogen, add 135 grams of deionized water, 5 grams of dihexyl sodium salt of sulfosuccinate, 4 grams of ethoxylated nonylphenol disodium phosphate half ester, 15 grams of methacrylic acid, Pre-emulsify 35 grams of methyl methacrylate, 200 grams of styrene, and 200 grams of butyl acrylate to obtain solution B. The solution B is a pre-emulsified mixed monomer; Dropwise add the pre-emulsified mixed monomers of solution B into the flask for reaction. The dropwise addition time is 90 minutes. After the dropwise addition is completed, continue the reaction at 80°C to 85°C for 30 minutes to prepare the seed core-shell emulsion;

[0036] Dissolve 0.4 grams of ammonium persulfate in 10 grams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com