Shield tail sealing grease special for shield machine and preparation method thereof

A shield tail seal and shield machine technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor water pressure resistance sealing performance and pumping performance, increased engineering costs, and high transportation costs, and achieves strong adhesion and improved. Work efficiency, improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In addition, the embodiment of the present invention also provides a preparation method of special shield tail sealing grease for shield machines, which includes: stirring the base oil, calcium carbonate and bentonite evenly, adding polyisobutylene, ethylene-propylene copolymer, and lubricating grease and heating to Stir and mix evenly at 50-70°C, then add plant fiber and synthetic fiber, stir and mix evenly at 50-70°C, then cool to room temperature while stirring. The method is simple and easy to operate. Through the reasonable selection and proportioning of raw material components and the above mixing, the special shield tail sealing grease provided by the embodiment of the invention can be prepared.

[0026]It is worth noting that in this method, the order of adding the components is to first mix the base oil, calcium carbonate and bentonite at room temperature, then add polyisobutylene, ethylene-propylene copolymer, grease, and heat to 50~ 70°C to make the semi-soli...

Embodiment 1

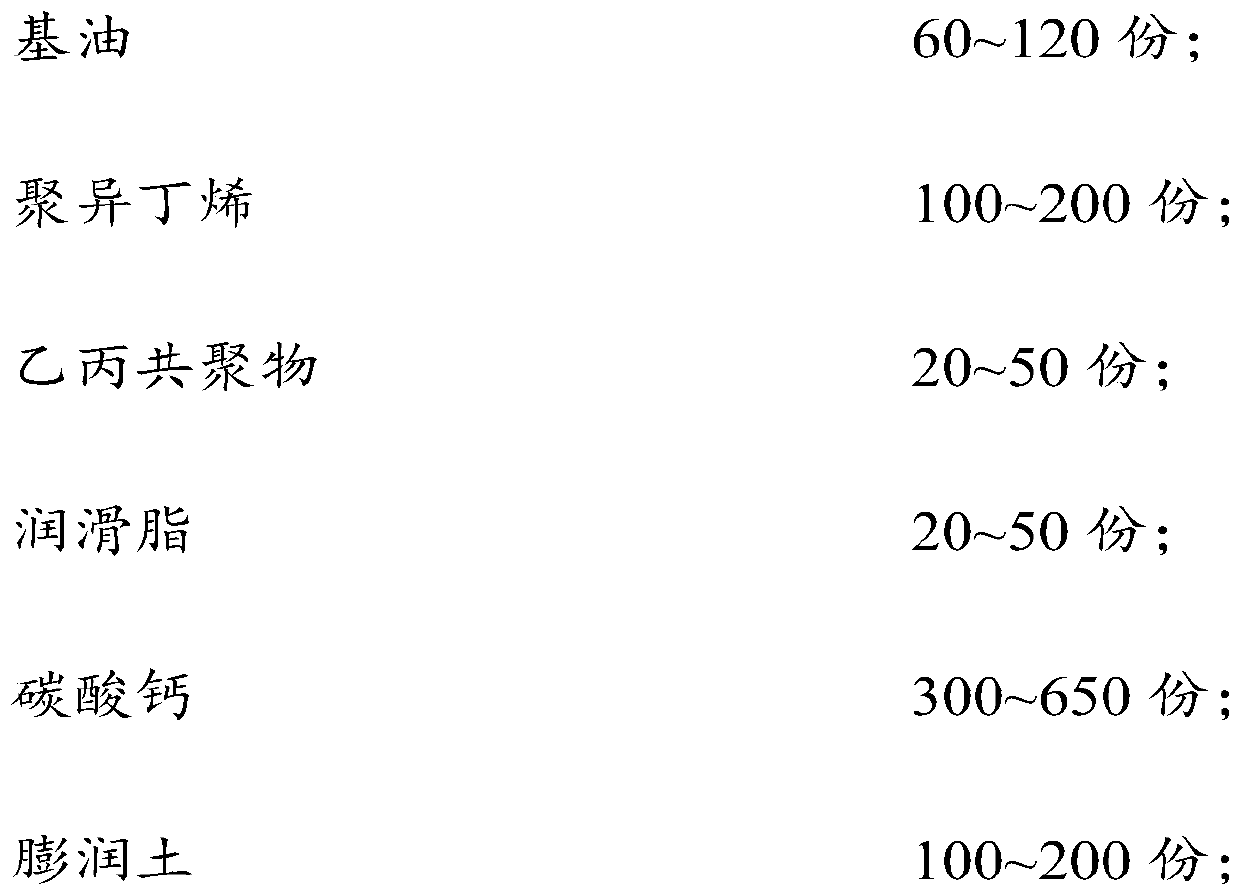

[0029] A special shield tail sealing grease for a shield machine, its components and the proportions by weight are as follows:

[0030]

[0031]

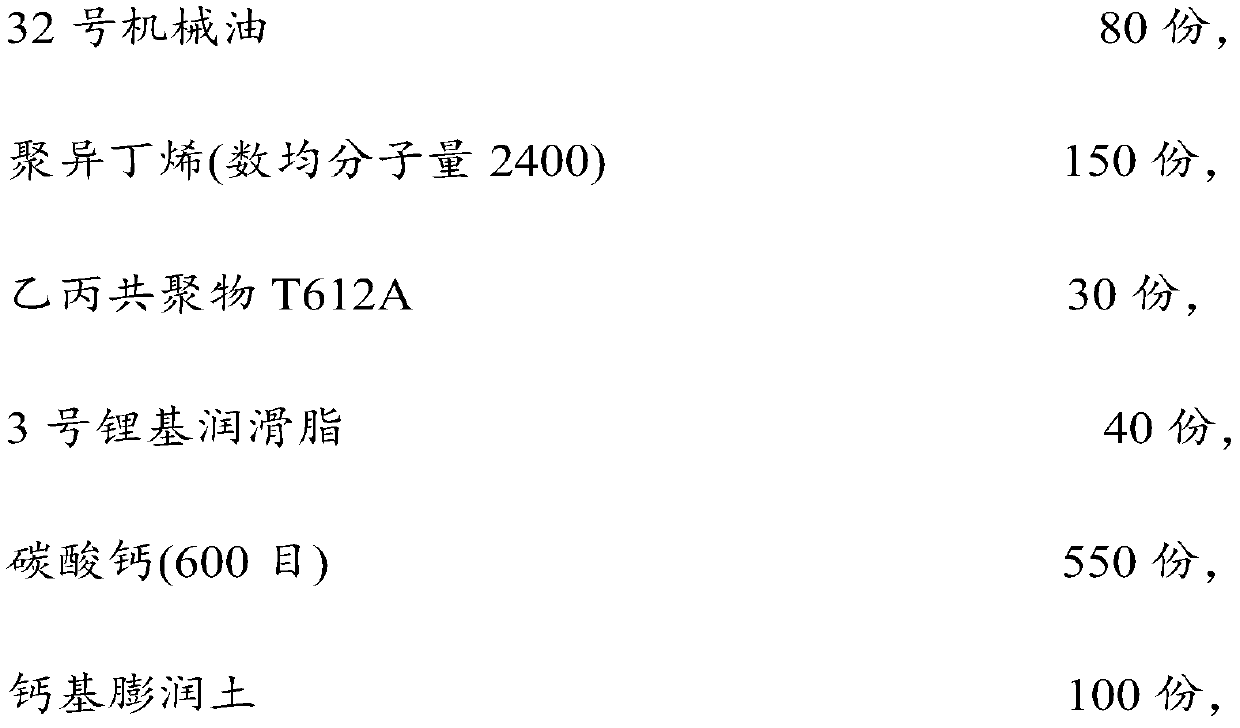

[0032] The preparation process is as follows: First, mix 80kg No. 32 mechanical oil, 550kg 600-mesh calcium carbonate and 100kg calcium-based bentonite in a mixing mixer at room temperature, then add 150kg polyisobutylene with a number average molecular weight of 2400, 30kg ethylene-propylene copolymer T612A, 40kg3 No. Lithium-based grease is heated to 60°C and stirred evenly, and finally 50kg of wood fibers with an average length of 2mm and 20kg (average length of 3mm, average diameter of 20 microns) of polyester fibers are added at 60°C and stirred evenly, then cooled while stirring To normal temperature, a kind of shield tail sealing grease specially used for shield machine can be obtained.

Embodiment 2

[0034] A special shield tail sealing grease for a shield machine, its components and their weight proportions are as follows:

[0035]

[0036]

[0037] The preparation process is as follows: first, mix 120kg No. 46 mechanical oil, 650kg 400-mesh calcium carbonate and 120kg sodium-based bentonite in a mixing mixer at room temperature, then add 200kg polyisobutylene with a number average molecular weight of 1000, 20kg ethylene-propylene copolymer T612, 5kg Heat No. 2 lithium-based lubricating grease to 50°C and mix evenly. Finally, add 25kg of cotton fibers with an average length of 1mm and 5kg of nylon fibers (average length of 5mm, average diameter of 10 microns) and stir at 50°C. Cool to normal temperature to get a kind of special shield tail sealing grease for shield machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com