Improved Tibet lamb skin clean production technology

A production process and technology of Tan sheepskin, which is applied in chemical treatment equipment for leather/skin/leather/raw hide, chemical treatment of small raw hides/large raw hides/leather hides/furs, chemical treatment before tanning, etc. It can solve the problem of waste liquid treatment and utilization. The efficiency is not high, the Tan sheepskin production process pollutes the environment, etc., to stably maintain the shape and softness, avoid the loss of collagen, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

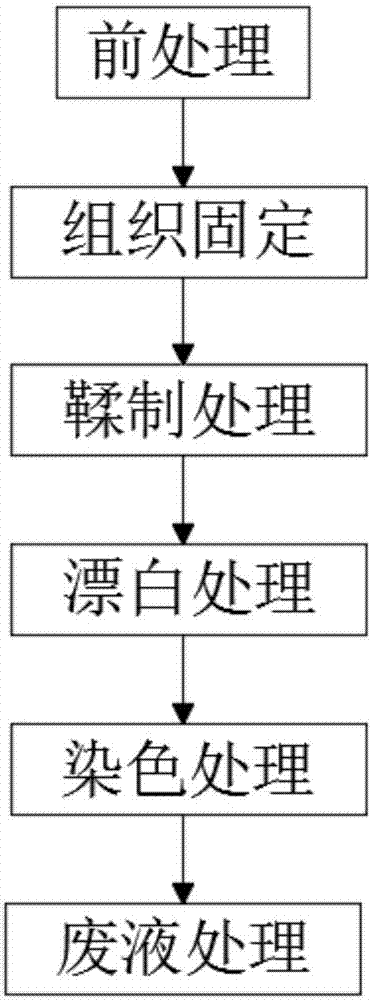

[0022] Example 1, such as figure 1 Shown:

[0023] An improved clean production process for Tan sheepskin, comprising the following steps:

[0024] (1) Pre-treatment: Trim the burrs on the corners of the Tan sheepskin, remove the burrs on the corners of the Tan sheepskin, then scrape and degrease the flesh of the Tan sheepskin, soak in salt water for 2h-3h;

[0025] (2) Tissue fixation: Mix glutaraldehyde, glycerin, phenol and polyethylene glycol according to the concentration ratio of 25:53:20:2 under ultrasonic vibration at 35°C to 45°C to adjust the pH of the solution The value is 9.0-11.0, and the Tan sheepskin is soaked in the mixed solution for 12h-15h;

[0026] (3) Tanning treatment: Tan sheepskin is tanned with a drum, the temperature of the tanning treatment is 32-35°C, the time is 3.5-3.8h, the pH of the tanning treatment solution is 5.5-6.0, and the compound tanning agent in the tanning treatment solution is The amount of 10-20g / L is added; the leather tanning pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com