A method of improving corrosion resistance and wear resistance of magnesium metal surface

A technology of corrosion resistance and wear resistance, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of restricting application effect and low wear resistance, and achieve improved corrosion resistance and wear resistance Improved abrasiveness and reduced destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

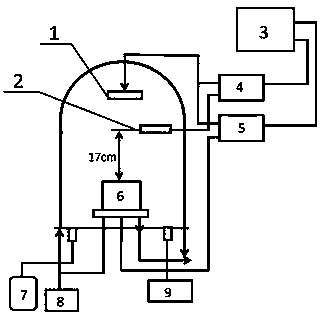

[0021] figure 1 It shows the double-glow plasma metallization furnace equipment used in the present invention, which mainly includes 9 parts, namely: 1-anode, 2-source, 3-control board, 4-source power supply, 5-workpiece power supply, 6-workpiece cathode, 7-argon gas, 8-cooling water, 9-vacuum device.

[0022] use figure 1 The device shown is to test a pure magnesium specimen with a thickness of 3mm and a side length of 10mm×10mm. The operation steps are as follows:

[0023] (1) Magnesium sample pretreatment: the magnesium sample was ground to 1200# with sandpaper, mechanically polished, and then ultrasonically cleaned in absolute ethanol.

[0024] (2) Put the pretreated magnesium sample into figure 1 On the sample stage of the double-glow plasma metallization furnace equipment shown, the planar graphite target is placed opposite to the sample, and the distance between the target and the sample is adjusted to 17cm.

[0025] (3) First use the vacuum device 9 to draw the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com