Calculation method for critical overlapping rate in laser cladding forming process for vertical surface

A technology of laser cladding and forming process, which is used in the improvement of process efficiency, metal material coating process, additive processing, etc., can solve the problem of inability to fuse the surface contour assumption, and achieve good surface flatness, simple and easy to achieve Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

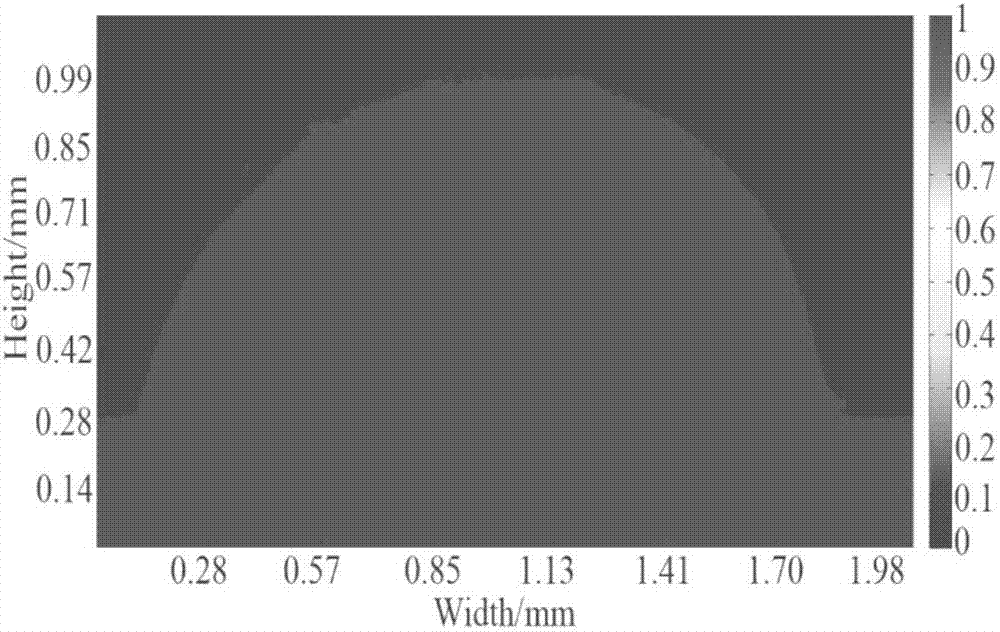

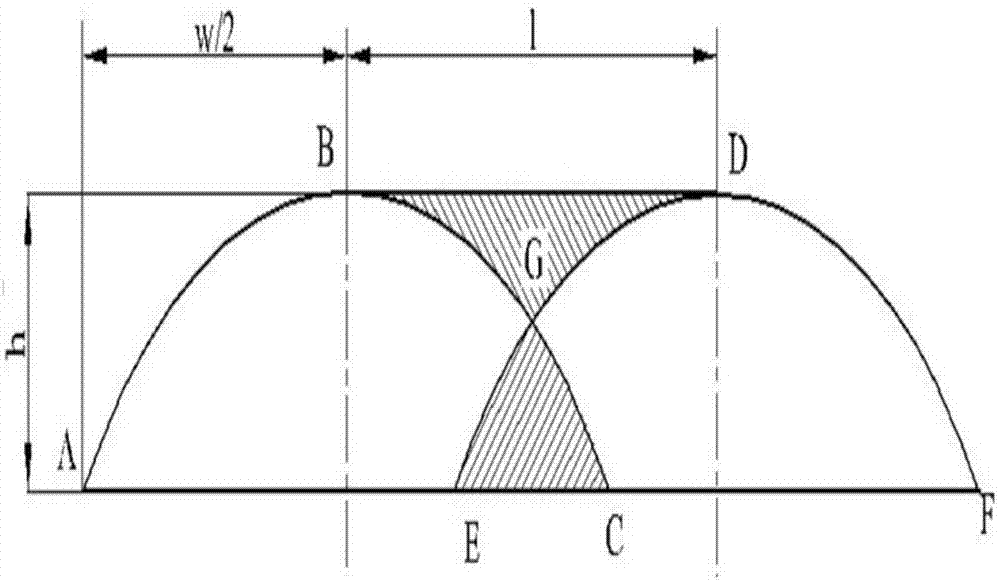

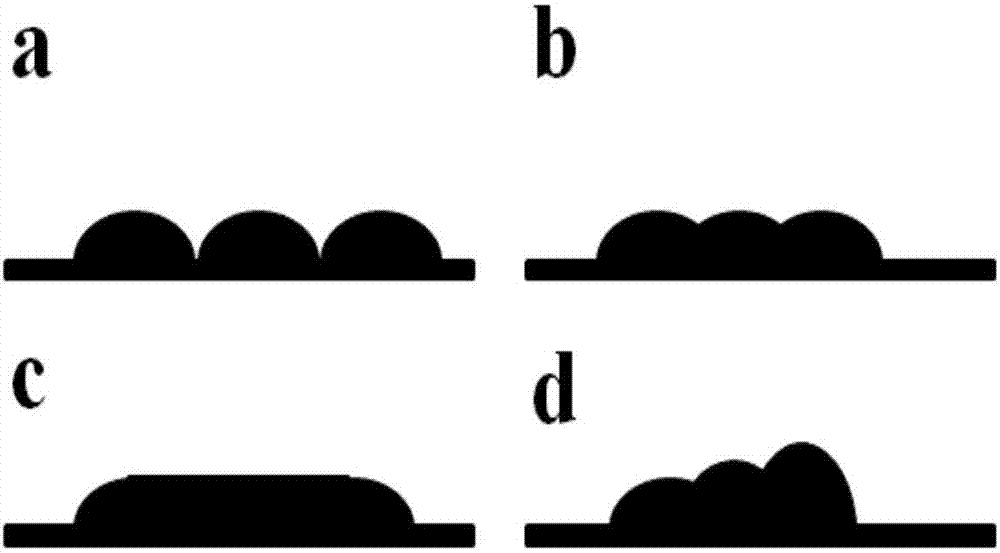

[0047] The present invention is a research on the facade laser cladding forming technology, and mainly studies a calculation method for the critical overlap rate suitable for the facade laser cladding forming process; at the same time, the critical offset of the facade melting channel is calculated according to different process parameters Modeling, and the significance test of the obtained regression equation model is carried out to establish the final regression equation.

[0048] The process equipment used in this research mainly includes: fiber laser, hollow laser light coaxial powder feeding nozzle, KUKA robot, workbench, powder feeding system and control center; some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com