Vapor phase corrosion inhibitor and preparation method thereof

A technology of gas phase corrosion inhibitor and benzoic acid, which is applied in the field of gas phase corrosion inhibitor and its preparation, can solve the problems of poor corrosion inhibition effect, achieve the effect of enhancing corrosion inhibition effect, improving volatile performance and gas phase corrosion inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

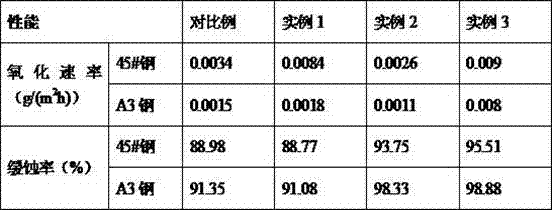

Examples

example 1

[0021] Weigh 20g of cysteine, 200mL of ether and 10g of benzoic acid into a three-necked flask equipped with a thermometer and a reflux device, place the three-necked flask in a water bath, control the temperature of the water bath to 50°C, stir and mix for 1min, and then add 0.1mL mass fraction is 96% sulfuric acid solution, stirred and reacted for 2h, filtered after the reaction to obtain the filter residue, that is, benzoic acid-modified cysteine, and finally in parts by weight, get 20 parts of benzoic acid-modified cysteine , 10 parts of catechol, 1 part of dicyclohexyl ammonium nitrite, and 60 parts of water were added to the mixer, stirred and mixed for 15 minutes, and charged to obtain a gas phase corrosion inhibitor.

example 2

[0023] Weigh 20g of cysteine, 200mL of ether and 10g of benzoic acid into a three-necked flask equipped with a thermometer and a reflux device, place the three-necked flask in a water bath, control the temperature of the water bath to 50°C, stir and mix for 1min, and then add 0.1mL mass fraction is 96% sulfuric acid solution, stirred and reacted for 2h, filtered after the reaction to obtain the filter residue, that is, benzoic acid-modified cysteine, and finally in parts by weight, get 20 parts of benzoic acid-modified cysteine , 10 parts of catechol, 6 parts of N-oleoyl sarcosine, 1 part of dicyclohexyl ammonium nitrite and 60 parts of water are added to the mixer, stirred and mixed for 15 minutes, and charged to obtain a gas phase corrosion inhibitor.

example 3

[0025] Weigh 20g of cysteine, 200mL of ether and 10g of benzoic acid into a three-necked flask equipped with a thermometer and a reflux device, place the three-necked flask in a water bath, control the temperature of the water bath to 50°C, stir and mix for 1min, and then add 0.1mL of sulfuric acid solution with a mass fraction of 96%, stirred and reacted for 2h, filtered after the reaction to obtain a filter residue, namely benzoic acid-modified cysteine, at the same time, 400g shells were added to a pulverizer and pulverized for 40min to obtain shell powder. Add powder, 100g diammonium hydrogen phosphate, 60g ammonium dihydrogen phosphate and 800mL water into the hydrothermal kettle, move the hydrothermal kettle into an oven, and react at a temperature of 150°C for 5 hours. After the reaction, place the product in a centrifuge In the machine, centrifuge at a speed of 4000r / min for 5min to obtain a precipitate, add the precipitate, 15g of carbon disulfide, 200g of grape skin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com