Environment-friendly water pipe cleaning coating treatment method

A treatment method and an environmentally friendly technology, applied in the field of water system pipeline treatment, can solve problems such as cooling capacity reduction, motor load increase, evaporator pressure drop, etc., and achieve the effect of speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The environmental-friendly water pipe cleaning and coating treatment method of this embodiment washes and cleans the cold and hot pipe networks, and chemically treats the waste liquid after cleaning and coating. Because there is a spare pipe for hot water, it needs to be connected to the original water supply or return pipe for rinsing, cleaning and coating cycle.

[0051] Since no chemicals are added in the water flushing stage, no water quality treatment is required, and the flushing water is discharged on the spot. In the cleaning and coating stage, a cleaning and coating agent is used, and calcium hydroxide + cyclohexylamine method is used to treat phosphorus-containing wastewater.

[0052] The treatment method of this example is used to clean and coat the paint slag of the pipe network of the frozen water hole hot water system in an amusement park in East China, and to chemically treat the waste liquid after cleaning and coating, so as to meet the requirements of t...

Embodiment 2

[0120] In this embodiment, the cold and hot pipe network of this embodiment washes and cleans the coating film, and carries out chemical treatment technology to the waste liquid after cleaning the coating film. The project objectives are:

[0121] (1) Complete the cleaning work of the main network, the cleaning water quality target is less than 20NTU, and the iron ion is less than 2ppm.

[0122] (2) Drainage in the process of adding tap water to degreasing meets GB3838-2002 "National Surface Water Environmental Quality Standard".

[0123] (3) Add desalinated water to clean the coating and the coating reaches the national standard.

[0124] (4) Clean the coating After the coating is finished, replenish the desalinated water in the cold storage tank, add bactericides, corrosion and scale inhibitors and color chemicals to ensure that the corrosion rates of copper and carbon steel in the pipe network system are 0.1MPY and 1.0MPY respectively. Finally, the normal operation of the ...

Embodiment 3

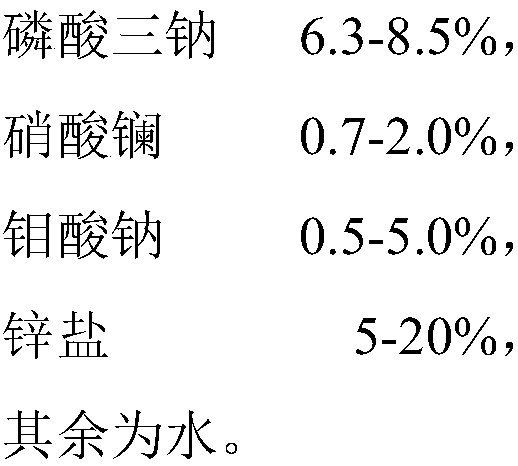

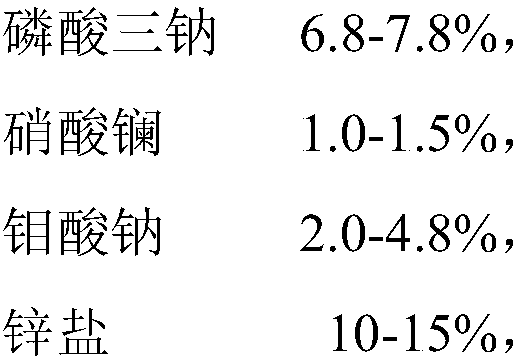

[0147] This embodiment is basically the same as Embodiment 1, except that in this embodiment, the cleaning and coating agent is composed of the following components in percentage by weight: trisodium phosphate 8.5%, lanthanum nitrate 0.7%, sodium molybdate 5.0%, Zinc salt 20%, the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com