Metal oxide/NiPi photo-anode material and preparation thereof

A technology of oxide and photoanode, applied in electrodes, electrolysis process, energy input, etc., to achieve the effect of improving photocurrent density and hole injection efficiency, improving charge transfer, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of Fe2O3 / NiPi photoanode preparation method is as follows:

[0040] (1) Preparation of FeOOH nanorod film on FTO: the formula is: 0.15M FeCl3: 0 ~ 1M NaNO3 (adjusting pH to 1.3 ~ 2) hydrothermal reaction solution is placed in the inner tank with FTO, the inner tank Seal it in an autoclave, conduct a hydrothermal reaction at 70-110° C. for 3-10 hours, wash, and dry to form a layer of light yellow transparent FeOOH nanorod film. Increasing the hydrothermal reaction time resulted in larger FeOOH nanorods.

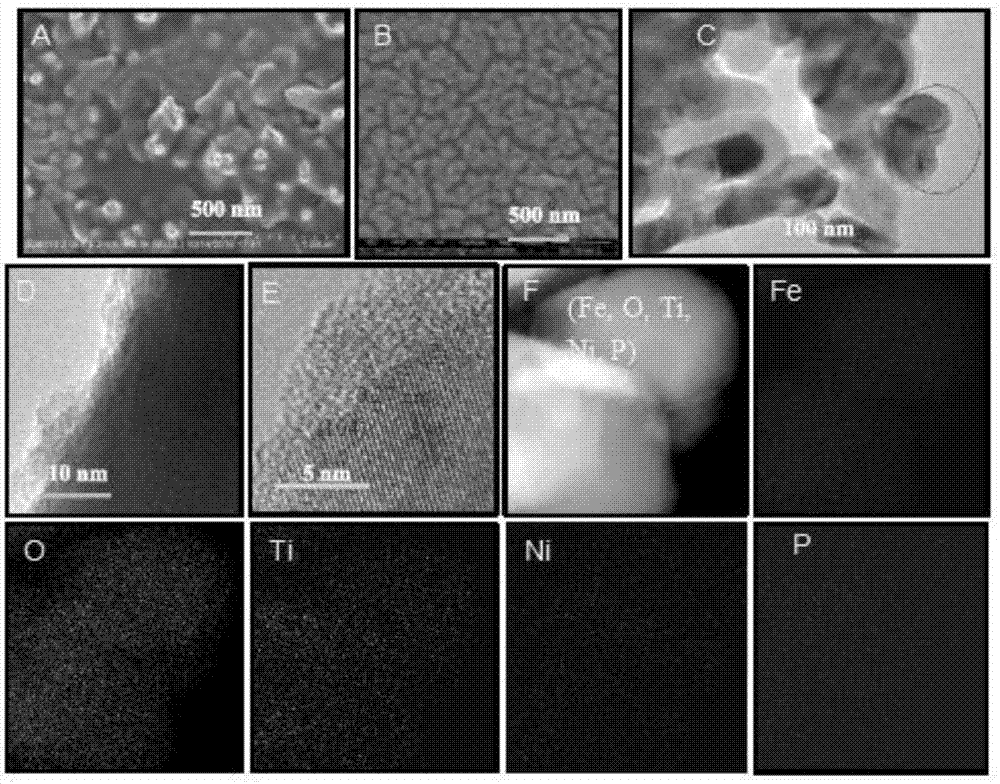

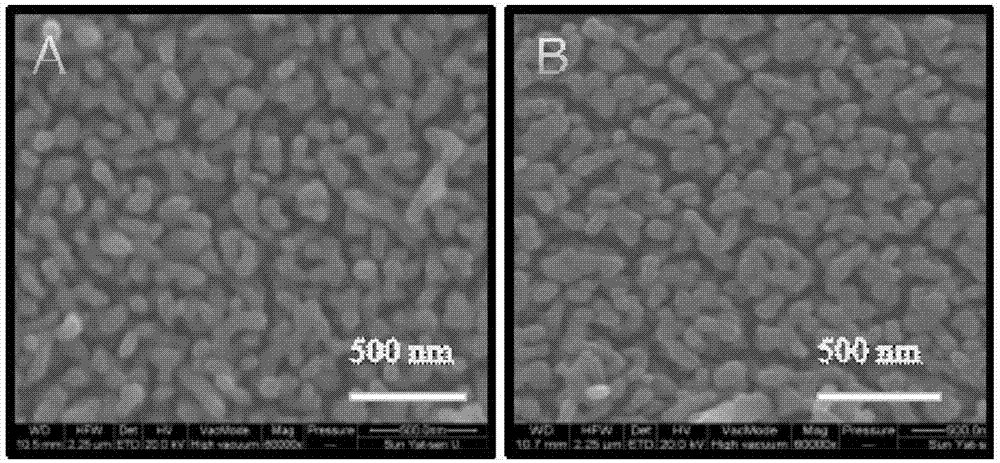

[0041] (2) Fe 2 o 3 Film preparation: the above-mentioned FeOOH film is placed in a tube furnace and calcined for 20-120 minutes when the temperature is raised to 500-750°C, cooled to room temperature and taken out to obtain red-red Fe2O3 and electrodes, the appearance of which is as follows: figure 1 A shows.

[0042] from figure 2 A can see Fe 2 o 3 The Fe 2p3 / 2 and 2p1 / 2 of the film are located at 710.4eV and 723.7 eV, respectively, which are Fe 2 o ...

Embodiment 2

[0051] a kind of Fe 2 o 3 / NiPi photoanode is prepared as follows:

[0052] (1) Preparation of 0-5% Ti:FeOOH nanorod film on FTO: the formula is: 0.15M FeCl 3 : 0~1MNaNO 3 : 0 ~ 7.5mM Ti solution (such as K 2 TiF 6 、TiCl 3 、TiCl 4 , TiCN, TiF 4 etc.) (adjust the pH to 1.3~2) hydrothermal reaction solution is placed in the liner equipped with FTO, seal the liner in the autoclave, perform hydrothermal reaction at 70-110°C for 3-10 hours, wash and dry , forming a layer of light yellow transparent 0-5% Ti:FeOOH nanorod film. Increasing the hydrothermal reaction time will result in larger size 0-5%Ti:FeOOH nanorods.

[0053] (2) 0~5%Ti:Fe 2 o 3 Film preparation: the above-mentioned 0-5% Ti:FeOOH film is placed in a tube furnace and calcined for 20-120 minutes when the temperature is raised to 500-750°C, cooled to room temperature and taken out to obtain red-red 0-5% Ti:Fe 2 o 3 electrodes, which look like figure 1 Shown in B. Such as figure 2 As shown in A and 2B, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com